Flameproof motors | 39

8.2.2. TYPE AND GREASE

CHARACTERISTICS

For standard temperature range, WEG ribbed

cooled motors, 2, 4 or more poles and tube cooled

motors 2 poles are supplied with POLYREX EM

103 grease (Supplier: Esso).

Tube cooled motors of 4 poles and more are

supplied with STABURAGS N12MF grease

(Supplier: Klüber), enough for the operating time

period indicated on the data sheet and on the

bearing identification nameplate.When the motors

are to be applied in negative ambient temperatures

they are supplied with grease AEROSHELL 22

(Suplier: Shell).

Characteristics of greases used on WEG motors:

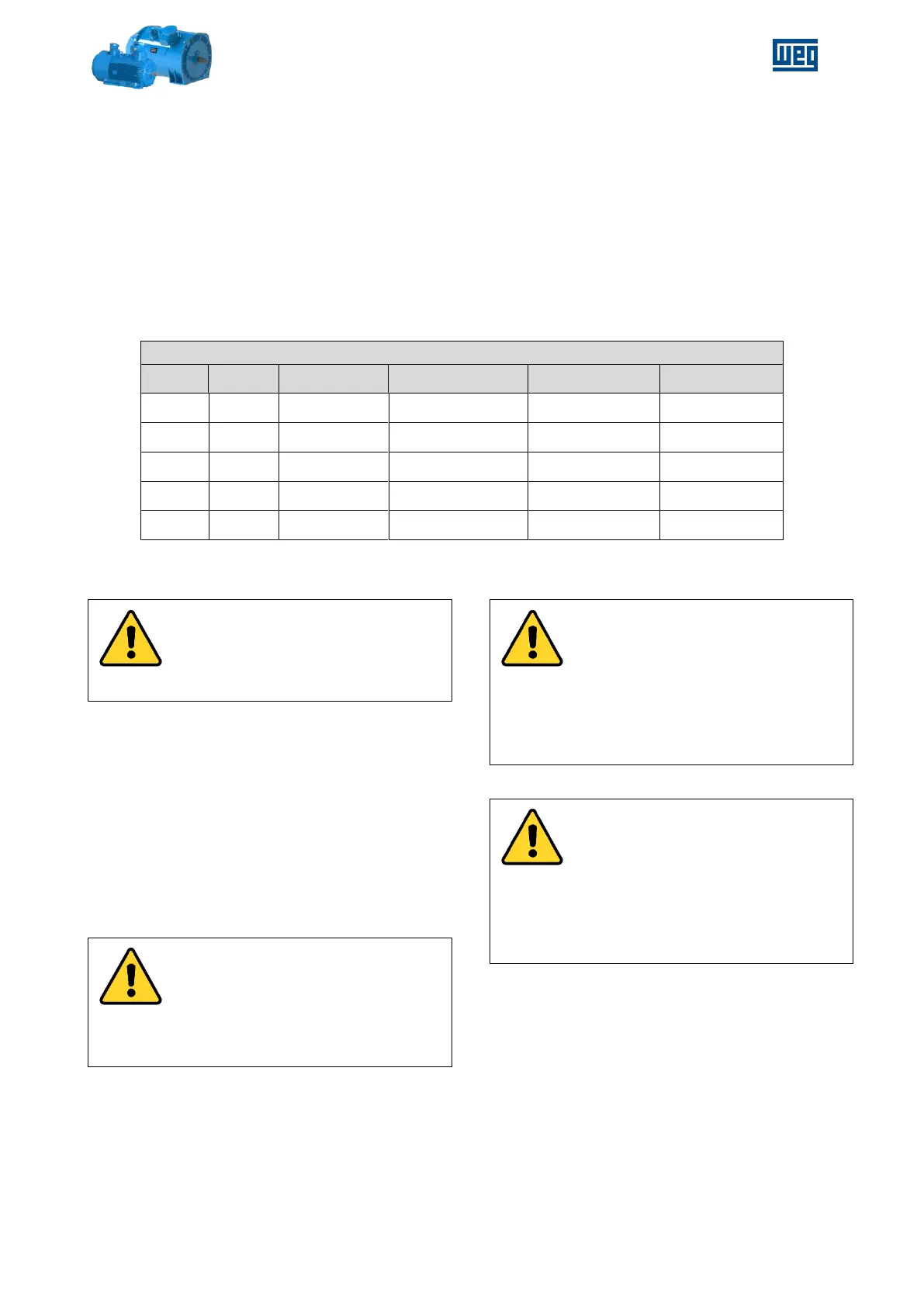

Table 8-1 - Greases for motors with bearings.

GREASES FOR MOTORS WITH BEARINGS

Mineral + ester +

Synthetic Hydrocarbon

For correct lubrication, always use the

type of lubricant indicated on the motor

nameplate.

8.2.3. LUBRICATION INTERVALS

Lubrication intervals depend on the motor speed,

working temperature, type of grease used and

working conditions.

The lubrication interval and type of bearings are

indicated on the motor nameplate.

Operational safety of these motors will depend on

the compliance of the lubrication intervals.

Motors kept in stock should be

relubricated every six months. Once

each 2 moths, shaft must be rotated in

order to have the grease

homogenized.

The bearings data, amount of grease

to use, type of grease and lubrication

intervals are informed in the nameplate

attached to the motor. We recommend

the carefully verification of these data

before carry out the bearings

lubrication procedure.

Lubrication intervals and amount of

grease given in the tables below

should only be taken as advisory

information. For relubrication, follow

the intervals and grease amounts

indicated on the identification

nameplate.

Loading...

Loading...