30 | Flameproof motors

2

cos121.1cos1

25,18836

1

1

1.1

2

alfaalfaK

RPMDPMT

N

FR

e

e

K

I

DPMTDPMV

alfa

alfaMI

alfaMI

This is a general calculation. Consult

the belt’s manufacturer for an accurate

value.

Always use pulleys duly balanced.

Avoid, in all cases, oversized keys as

these can cause unbalancing. In case

these instructions are not followed

accordingly, vibration levels will occur.

5.1.5.4 COUPLING ARRANGEMENT

FOR SLEEVE BEARING - AXIAL

CLEARANCE

Motors fitted with sleeve bearings should be

directly coupled to the driven machine or even

using a gearbox. Pulley/belt coupling is not

recommended.

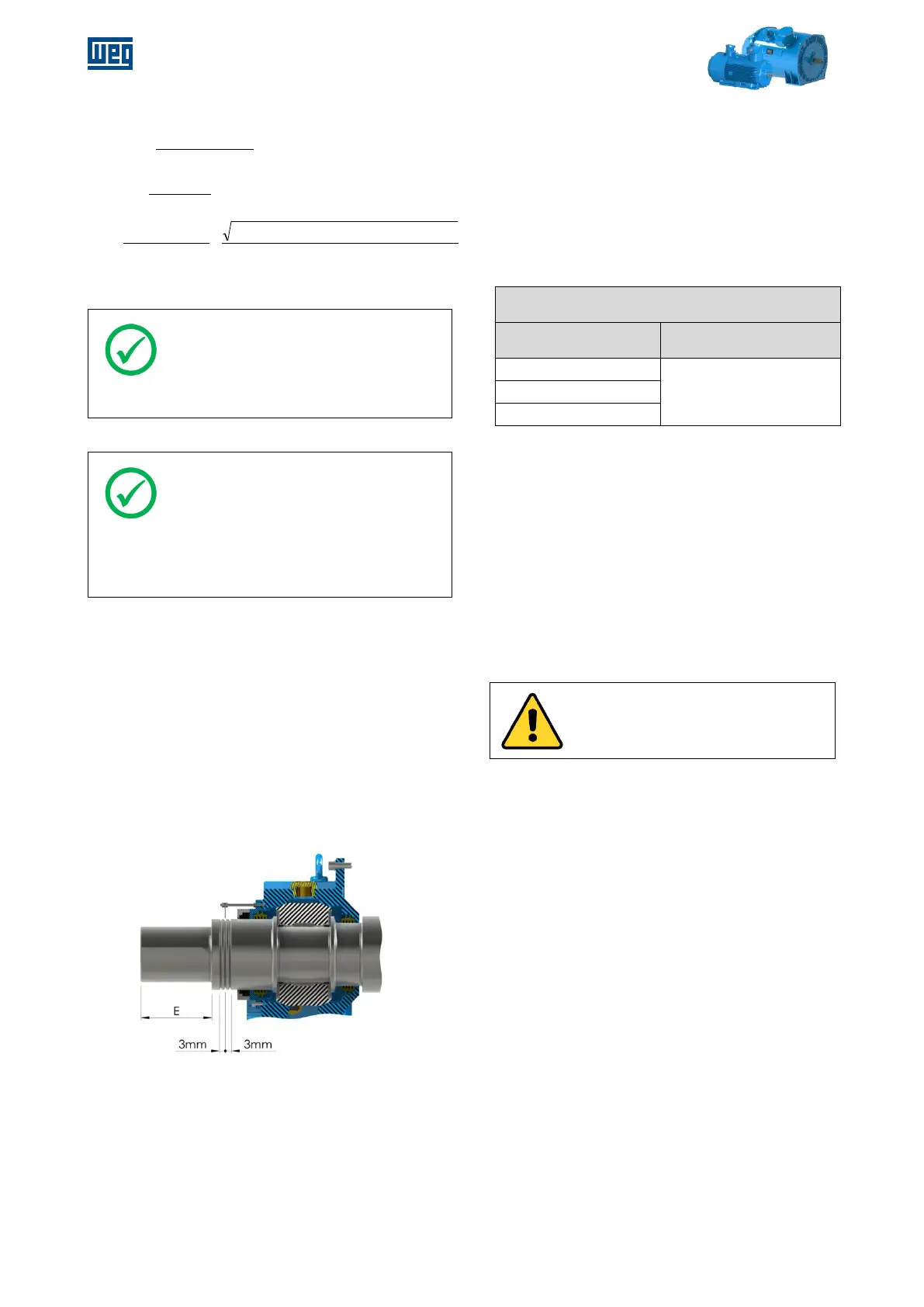

These sleeve bearing motors have three

identification marks on the shaft drive end. The

central mark is the indication of the magnetic

center; the other two outer marks indicate the

allowable limits for the rotor axial displacement.

Figure 5-16 - Sleeve bearing shaft alignment

The Figure 5-16 shows part of the bearing frame

where the arrow indicates the magnetic center and

the three marks on the shaft.

When coupling the motor, the following aspects

must be considered:

- Bearing axial clearance which is shown on the

table below for each bearing size.

- Axial displacement of the driven machine, if

any.

- Maximum axial clearance allowed by the

coupling.

Table 5-3 – Standard clearances applied to sleeve

bearings

Clearances applied to sleeve bearings for flameproof

motors supplied by WEG

(1) This is a standard value. Other values can be used

according to the motor project.

The motor must be coupled in such a way that the

arrow attached to the bearing frame be positioned

exactly on the central mark while motor is in

operation.

During motor starting or even under operation,

rotor should move freely between the two external

slots if the driven machine creates any axial force

on the motor shaft. Under no circunstance, motor

can operate continuously with axial force on the

bearing.

Rotor is not self alligned.

Sleeve bearings normally used by WEG are not

designed to withstand axial forces continuously.

The driven machine should have its axial end play

limited as necessary to prevent applying any axial

load to the motor sleeve bearings.

The Figure 5-17 shows part of the drive end

bearing highlighting a basic configuration of the

shaft/bearing set as well as axial clearances.

Loading...

Loading...