56 | Flameproof motors

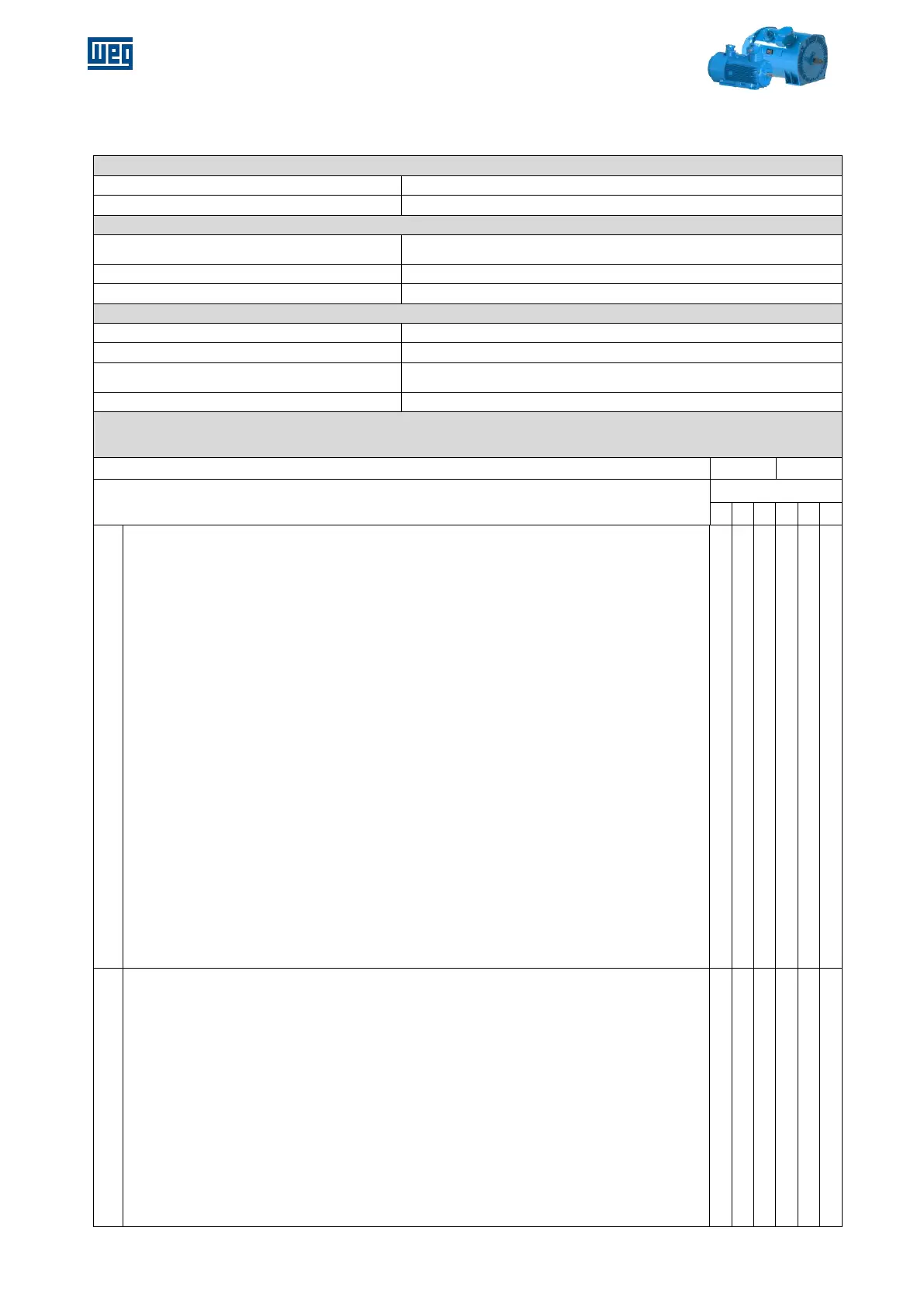

Table 9-1 - Maintenance plan

- Check noise and vibration.

- Regrease: follow regreasing intervals based on lubrication

instructions.

- After a week: check alignment and fixation and eventually refasten.

- Record measured figures.

ANNUALLY (Complete revision)

- Visual inspection; Measure insulation resistance.

- Clean inside of terminal box;

- Refasten bolts.

- Check alignment and refasten bolts

EVERY 2 YEARS (Inspection for Ex”d” and Ex”t” motors, according to the standard

IEC 60079-17)

Grade of inspection D = Detailed, C = Close, V = Visual

Equipment is appropriate to the EPL/Zone requirements of the location

Equipment group is correct

Equipment temperature class is correct (only for gas)

Equipment maximum surface temperature is correct (only for dust)

Degree of protection (IP grade) of equipment is appropriate for the level of protection/group

Equipment circuit identification is correct

Equipment circuit identification is available

Enclosure, glass parts and glass-to-metal sealing gaskets and/or compounds are satisfactory

There is no damage or unauthorized modifications

There is no evidence of unauthorized modifications

Bolts, cable entry devices (direct and indirect) and blanking elements are of the correct type and are

complete and tight

Threaded covers on enclosures are of the correct type, are tight and secured

Joint surfaces are clean and undamaged and gaskets, if any, are satisfactory and positioned correctly

Condition of enclosure gaskets is satisfactory

There is no evidence of ingress of water or dust in the enclosures in accordance with the IP rating

Dimensions of flanged joint gaps are:

- within the limits in accordance with manufacturer’s documentation or

- within maximum values permitted by relevant construction standard at time of installation or

- Within maximum values permitted by site documentation

Electrical connections are tight

Breathing and draining devices are satisfactory

Motor fans have sufficient clearance to enclosure and/or covers, cooling systems are undamaged,

motor foundations have no indentations or cracks.

The ventilation air flow is not impeded

Insulation resistance (IR) of the motor winding is satisfatory

Type of cable is appropriate

There is no obvious damage to cables

Sealing of trunking, ducts, pipes and/or conduits is satisfactory

Stopping boxes and cable boxes are correctly filled

Integrity of conduit system and interface with mixed system is maintained

Earthing connections including any supplementary earthing bonding connections are satisfactory (for

example connections are tight and conductors are of sufficient cross-section)

Fault loop impedance (TN systems) or earthing resistance (IT systems) is satisfactory

Insulation resistance is satisfatory

Automatic electrical protective devices are set correctly (auto-reset not possible)

Automatic electrical protective devices operate within permitted limits

Specific conditions of use (if applicable) are complied with

Cables not in use are correctly terminated

Obstructions adjacent to flameproof flanged joints are in accordance with IEC 60079-14

Variable voltage/frequency installation in accordance with documentation

Loading...

Loading...