46

instructions for the user

!

If the problem cannot be resolved, turn the machine o and call for Technical Assistance. Do not attempt any sort of repairs.

The descaling of the machine must be carried out by professional technicians to ensure that such operation does not lead to

release of hazardous materials for food use.

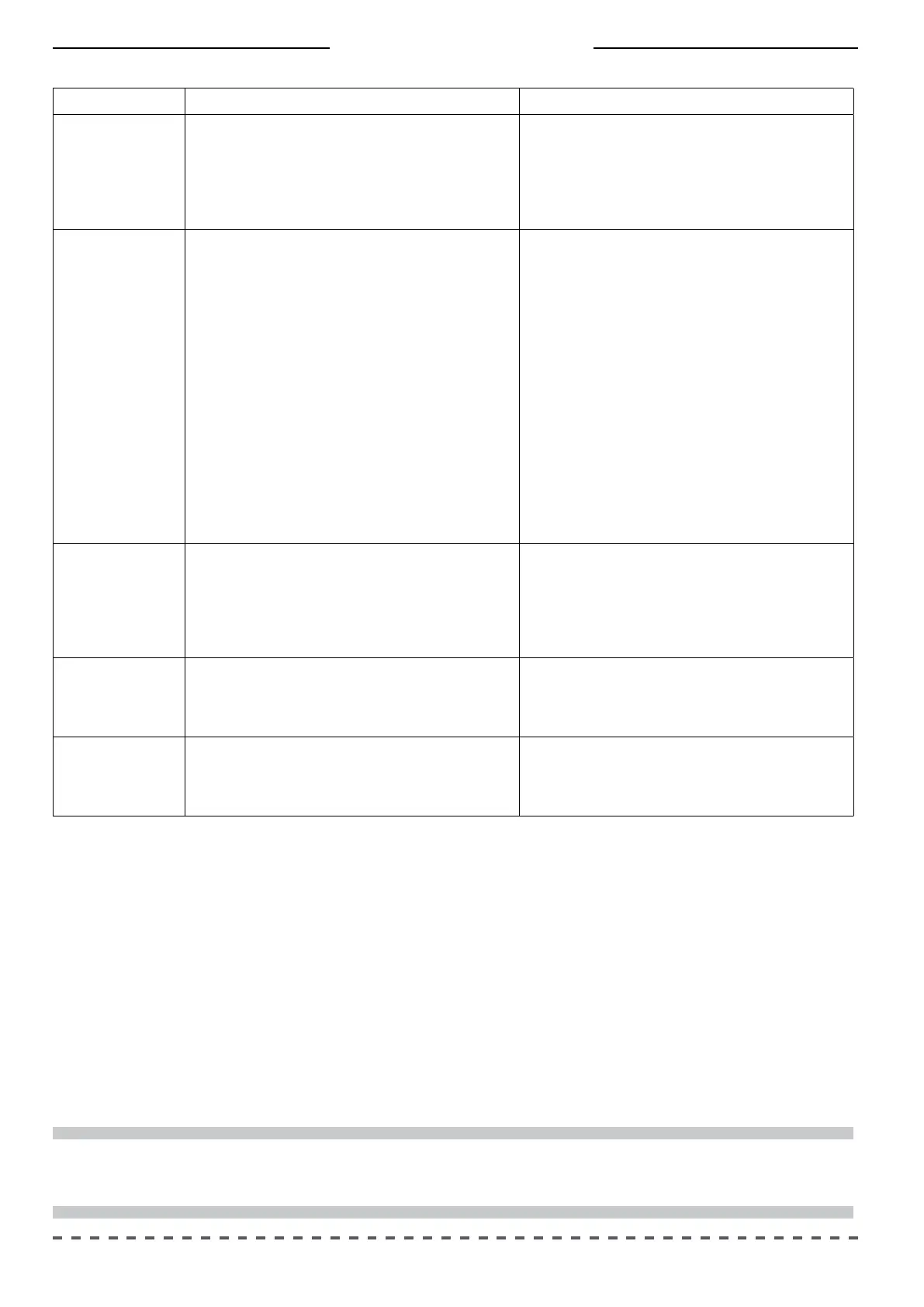

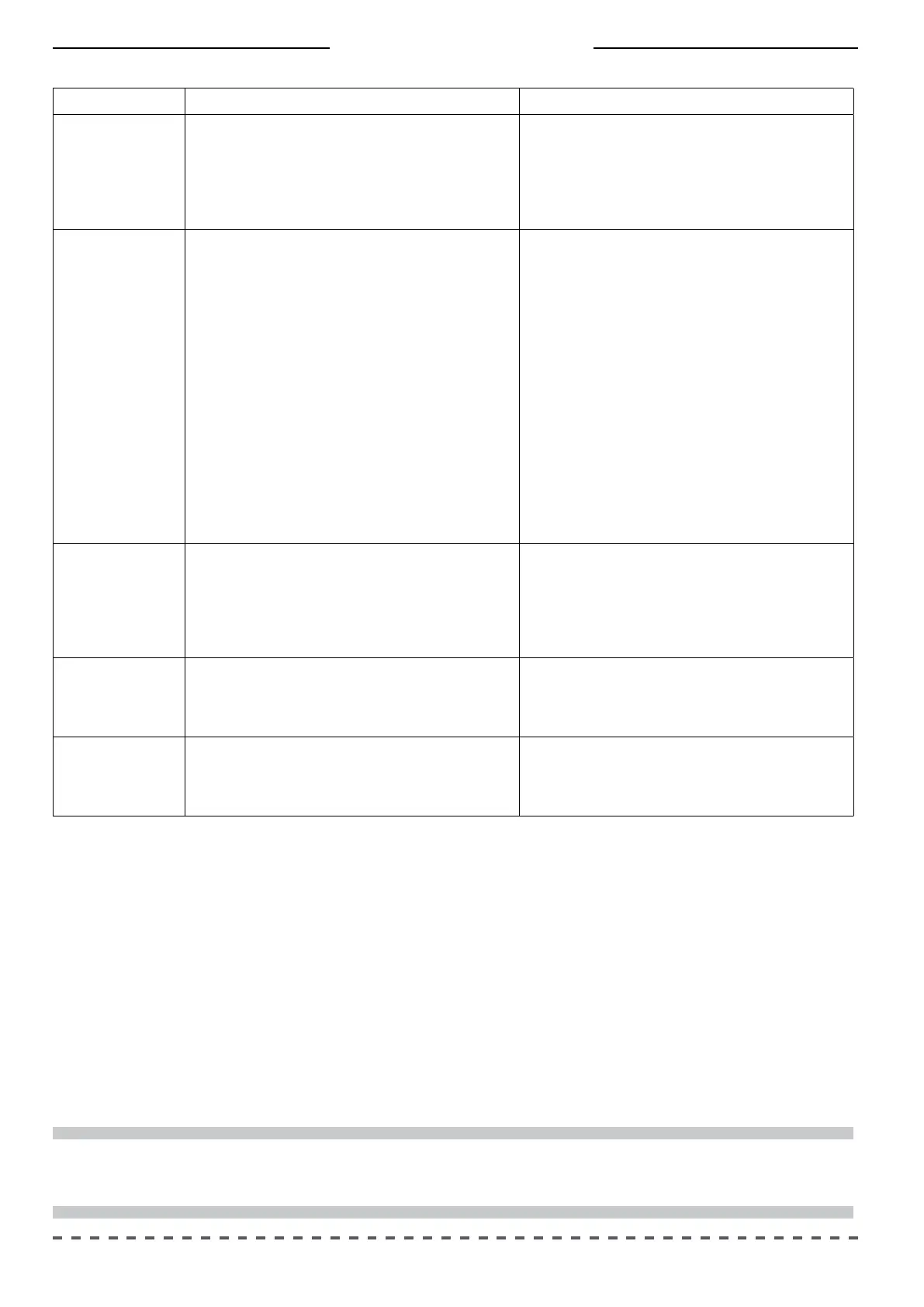

INDICATION CAUSE SOLUTION

GROUNDS IN CUP • The temperature of the delivery water is high • Change the temperature of the unit and/or boiler

INCORRECT COFFEE

DELIVERY

THE COFFEE DOSE IS

NOT MET

• The connection of the volumetric dosing device is faulty

• The connection of the electronic control unit is faulty

• The connector of the volumetric dosing device has humidity on it

• The volumetric dosing device is faulty: during delivery the

dosing device, LED does not ash

• The non-return valve loses pressure (the dose is too small)

• The drain valves lose pressure (the dose is too small)

• Water leakage from the group solenoid valve during coee

delivery or when in stand-by

• The volumetric dosing device is partially obstructed

• Check for proper connection of the volumetric dosing device

connector

• Check for proper connection of the electronic control unit

connector

• Remove the connector of the volumetric dosing device and

thoroughly dry the contacts

• Replace the heads of the volumetric dosing device or replace

the dosing device

• Check and replace the non-return valve, if necessary

• Check and replace the drain valves, if necessary

• Clean and replace the solenoid valve, if necessary

• Clean or replace the volumetric dosing device

THE VIBRATION PUMP

FUNCTIONS BELOW

NOMINAL CAPACITY

• The inlet is clogged, perhaps only partially

• The inside of the pump is damaged due to the inltration of

foreign materials

• Clean the tank lter and the water through lters

• Replace the vibration pump

THE CUP IS DIRTY WITH

SPLASHED COFFEE

• Steam pockets in the delivery system

• Air pockets in the hydraulic circuit

• Decrease the temperature of the unit and/or boiler

• Perform some empty runs

DOSE VOLUME

DIFFERENT FROM THE

ONE PROGRAMMED

• Air pockets in the hydraulic circuit • Bleed as shown in chap. 7.2

Loading...

Loading...