45

instructions for the user

ENGLISH

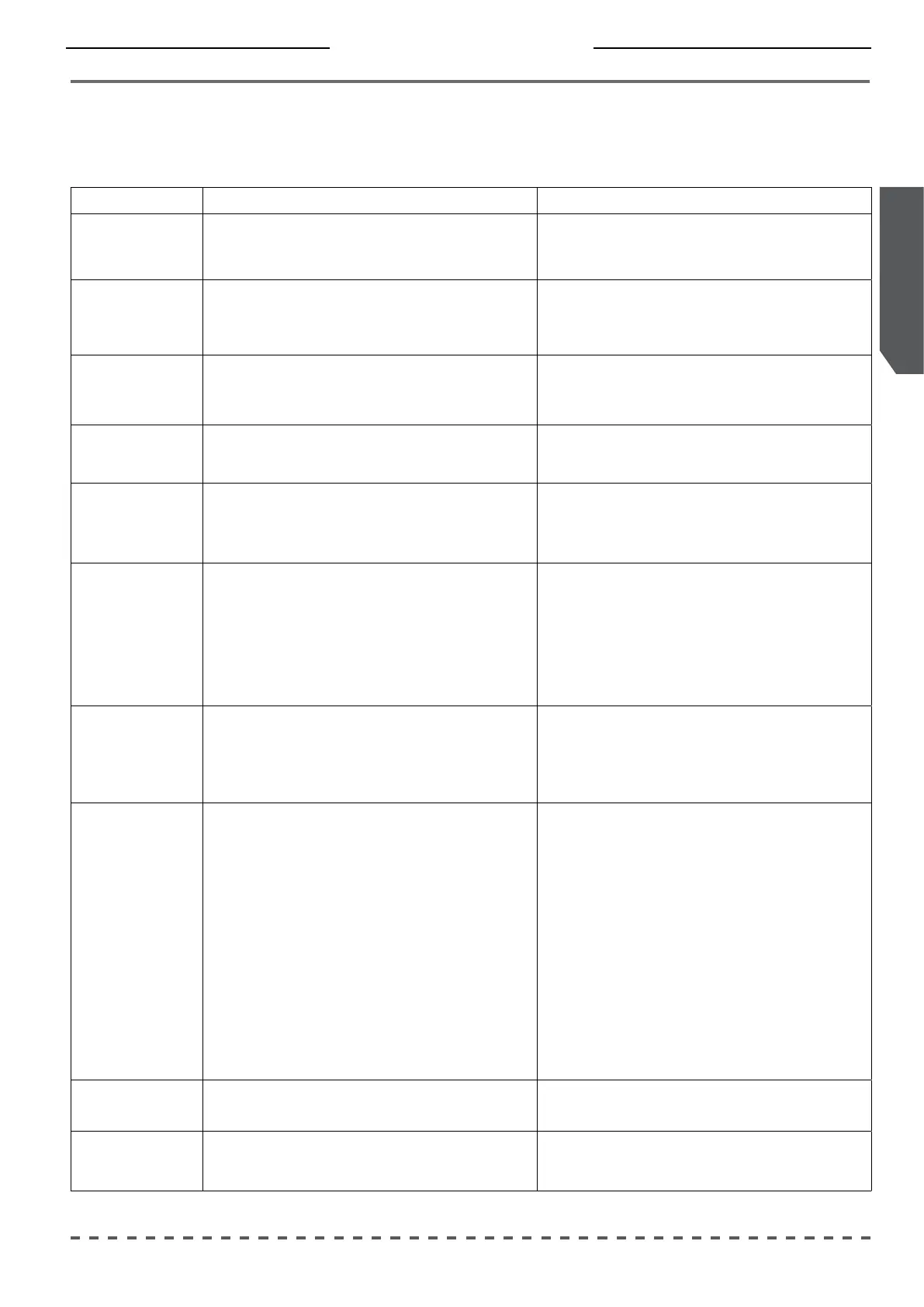

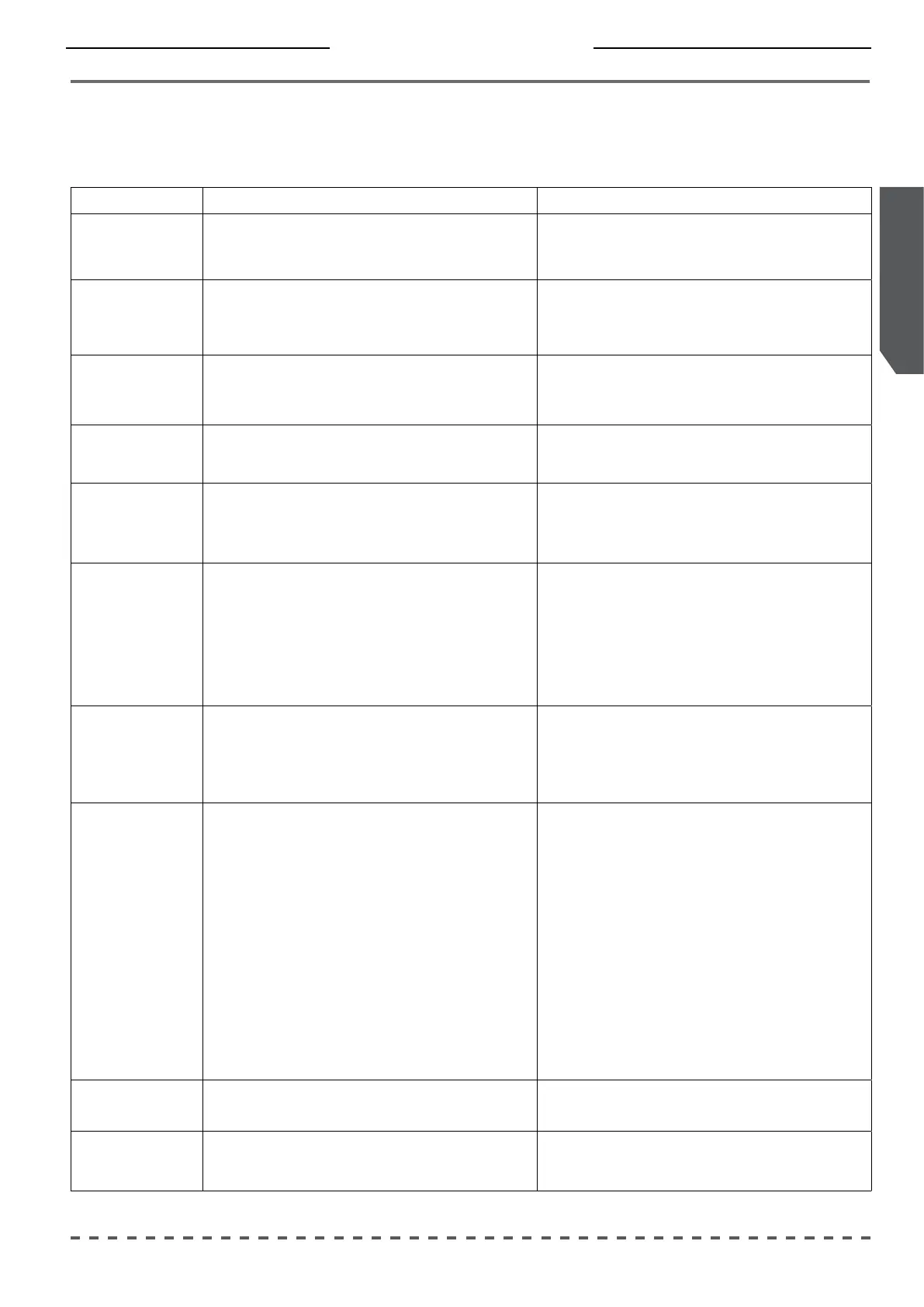

19 Malfunctions and related solutions

INDICATION CAUSE SOLUTION

MACHINE LACKING

POWER

• The machine switch is in the "OFF" position

• The machine switch is broken

• The wiring is defective

• Place the machine switch in the "ON" position

• Replace the main switch.

• Check for any faulty connections

NO WATER IN BOILER

• There is no water in the internal tank

• The vibration pump is disconnected or jammed.

• The water lling solenoid valve is defective

• Fill the internal tank with water

• Check the vibration pump

• Replace the water lling solenoid valve

TOO MUCH WATER IN

THE BOILER

• The boiler lling solenoid valve is broken

• The boiler lling solenoid valve is stays on

• Replace the boiler lling solenoid valve

• Check the level probe, the earth of the frame and

the operation of the electronic control unit

STEAM DOES NOT COME

OUT OF THE NOZZLE

• The nozzle sprayer is clogged

• Machine switch in “OFF” position

• Clean the steam nozzle sprayer

• Place the machine switch in the "ON" position

STEAM MIXED WITH

WATER COMES OUT OF

THE NOZZLES

• The boiler level is too high

• Check the status of the level probe: check if it is positioned

correctly and check for any surface lime scale

NO DELIVERY

• There is no water in the internal tank

• The group solenoid valve is clogged or broken

• The vibration pump is jammed

• The volumetric dosing device is blocked

• Fill the internal tank with water

• Clean or replace the unit solenoid valve

• Replace the vibration pump

• Check or replace the dosing device

• Carry out the bleeding and stabilization procedure as

described in par. 7.2

WATER LEAKS FROM

THE APPLIANCE

• The drainage tray is full

• The drain pipe is broken or detached or the water ow is

obstructed.

• Leaks in the hydraulic circuit.

• Drain the pan

• Check and restore the connection of the drain pipe to the pan

• Identify and eliminate any hydraulic leaks

COFFEE IS TOO COLD

• The temperature of the unit or boiler is too low

• The unit's electrical heating element is defective

• The wiring is faulty

• Lime scale on the exchangers and/or boiler heating element

• The heating element protection thermostat intervened

• Machine switch in “OFF” position

• Lime scale has reduced the circulation of water

• The dispensing unit is cold

• Change the temperature of the unit and/or boiler

• Replace the unit's electrical heating element

• Check for any faulty connections

• Clean the machine

• Reset the heating element protection

• Place the machine switch in the "ON" position

• Clean the connections of the exchanger, and clean or replace

the circulation tubes

• Wait a few minutes for the entire heating of the machine and

then make some empty runs.

• Perform the descaling

COFFEE DISPENSED

TOO QUICKLY

• Boiler temperature is too high • Modify the boiler temperature

COFFEE DISPENSED

TOO SLOWLY

• The dispensing unit is clogged • Check and clean the dispensing unit

Loading...

Loading...