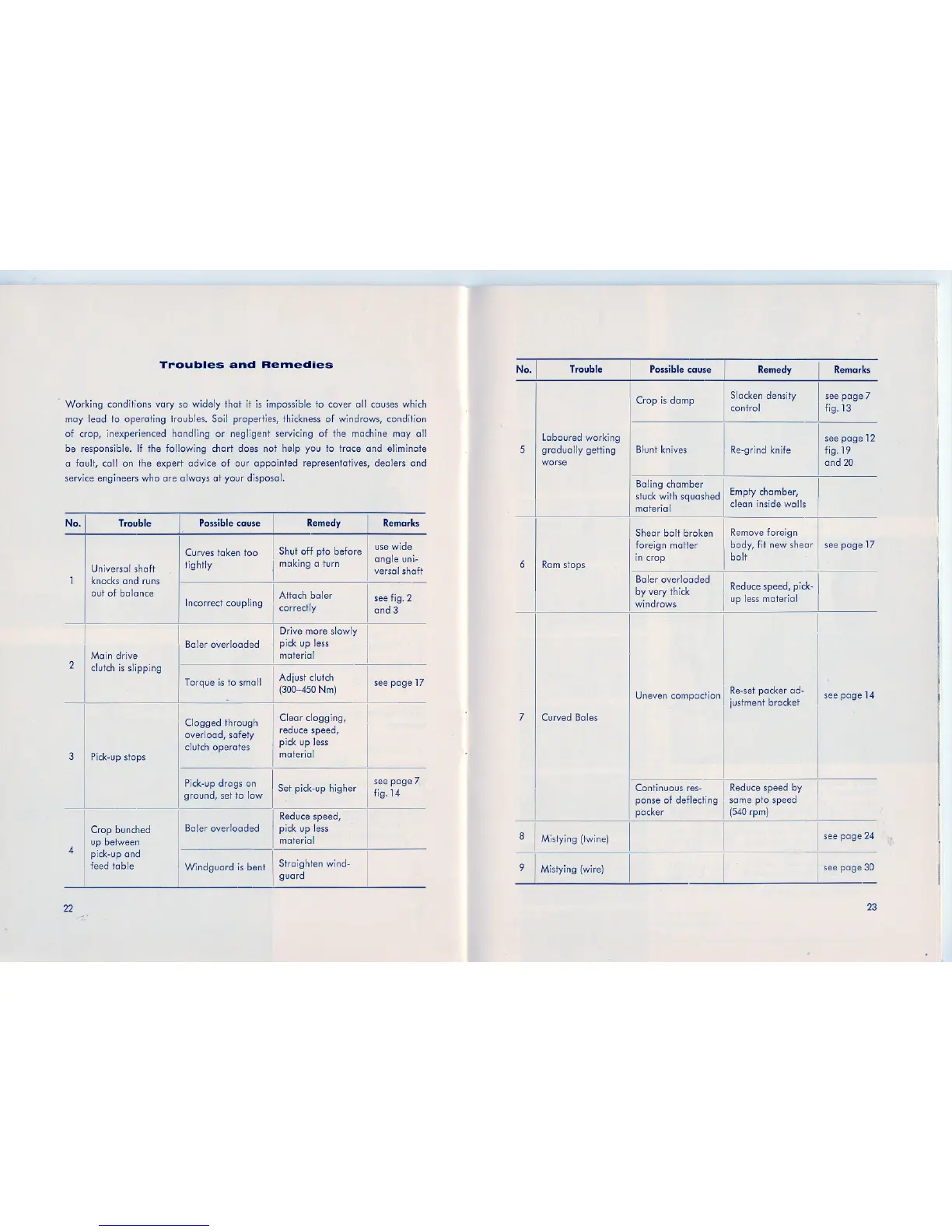

Troubles and Rernedies

.Working conditions vary so wide.ly that it is impossible to cover oll causes which

may lead to operating troubles. Seil properties, thickness of windrows, condition

of crap, inexperienced handling or negligent servicing of the machine may a,1I

be responsible. If the following chart does not help you to trace end eliminate

a fault, call on the expert advice of our appointed representatives, dealers end

service engineers who are always af your disposal.

...

-.- -

-. =-~= ~,~

~ Trouble! Possiblec~1 Remedy Remarks

'

l

i"

.'

111

i

}

.J

I

I

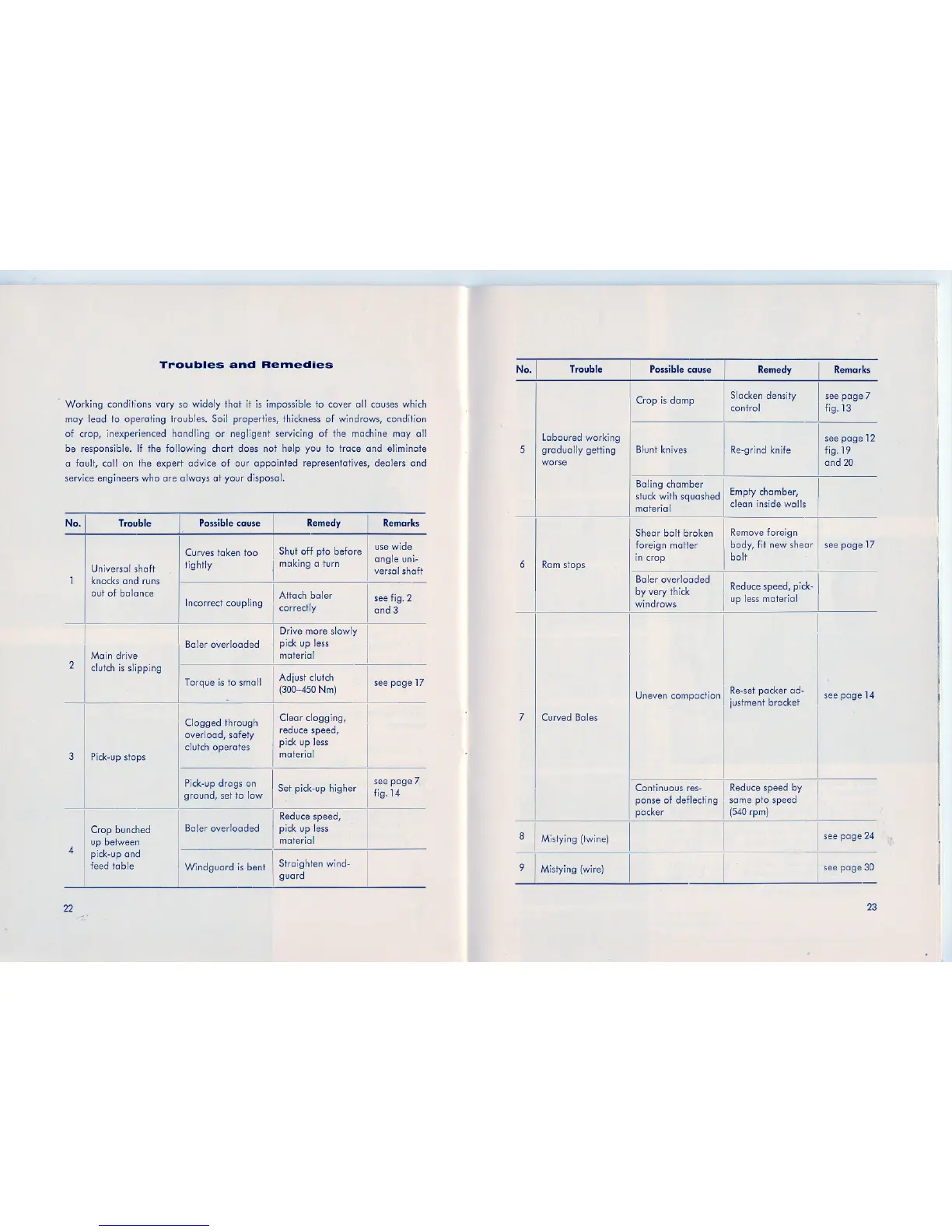

8 I Mistying(twine)

9 f Mistyihg (wire)

.

1

Continuous res- I Reduce speed by

ponse of deflecting

I

same pto speed

Ipacker (540rpm)

I I

I r

I

I

I see page 24

r see page 30

"

23

No. I

Trouble Possible causa

I

Remedy

I

Remarks

Curves taken tao

I Shutoff pto before

usa wide

angle uni,-

Universal shaft

tight,ly

I making aturn

versal shaft

1

knacks end runs

out of balance

I Attach baler

I seefig. 2

-

Incorrect C:UPli:9 .[ correctly

land 3

I BQleVO"ooded

I Drive more slowly

I

I pick up lass I

Main dri,ve

material

2

I dutch is slipping

I Adjust clutch

Torque is to smaH

I see page 17

(300-450 Nm)

Clogged through

I Clear clogging,

overload, safety

reduce speed,

clutch operates

pick up less

3

I Pick-up stops

I

material

I

Pick-up drags on

I Set pick-op high.,

I seepage7

ground, set to lew

I fig.14

Reduce speed,

I

Crop bunched

I Baler overloaded

I pick up lass

4

up between

materi.al

I

I pick-up end

I fe.edfable

I Windguard isbellt I Straightenwind-

I guard

22

'-

I Crop is damp

Slacken density I seepage7

control

I fig.13

laboured working

1.,-g"Od '0;1,

see page 12

5

gradually getting

BI'unt knivas

fig.19

worse

end 20

Baling chamber

Empty chamber,

I

stuck with squashed

material

clean inside waJls

I

I Shearbolt broken

Removeforeign I

foreign matter

body, fhtnewshear I seepage 17

6

Ram stops

in crop

bolt .

Baler overloaded

I Reducespeed,pick-

by very thick

windrows

I up less material

. I Re-setpackerad-

see page 14

Uneven compachon

. b k

lustment rac et

7

Curved Bales

-.-.

Loading...

Loading...