14

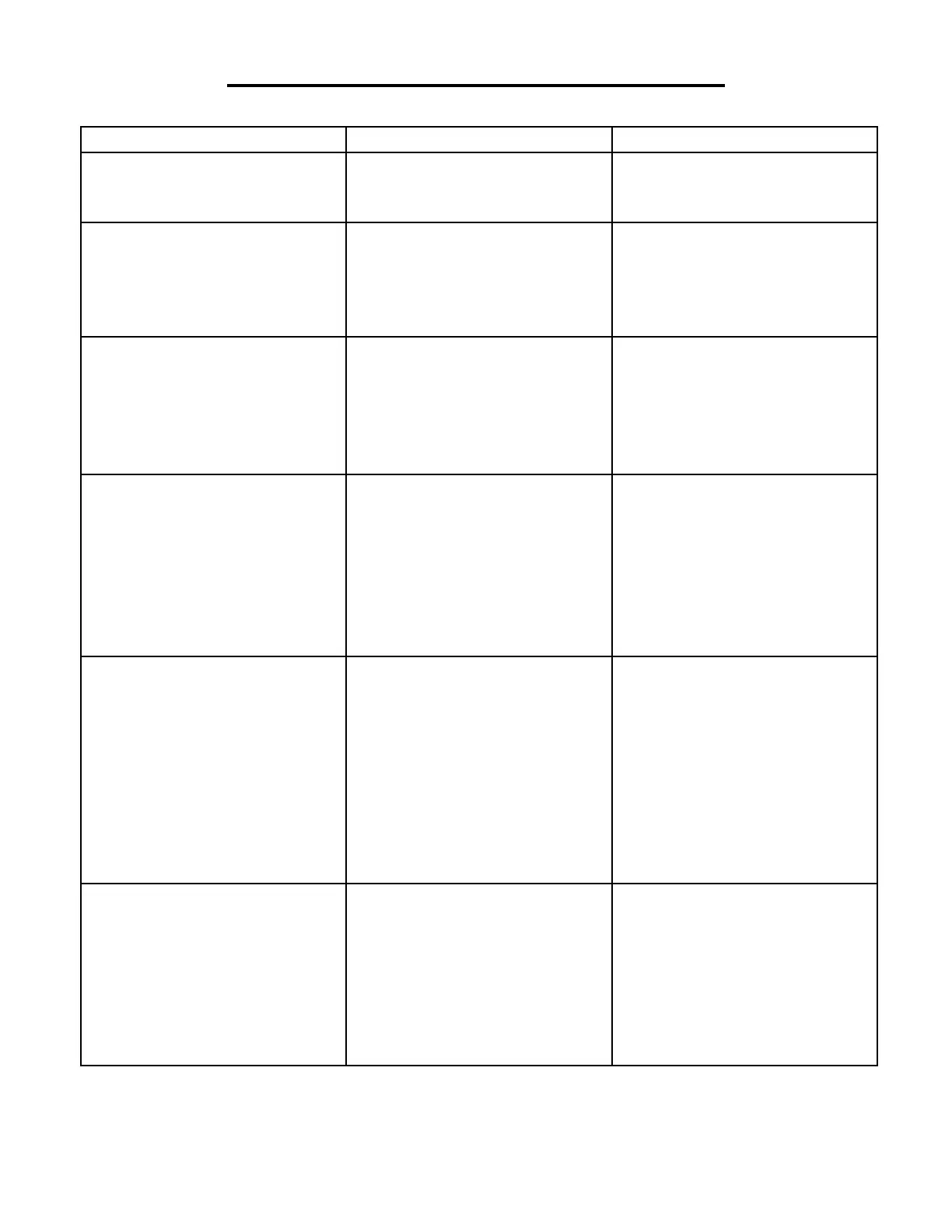

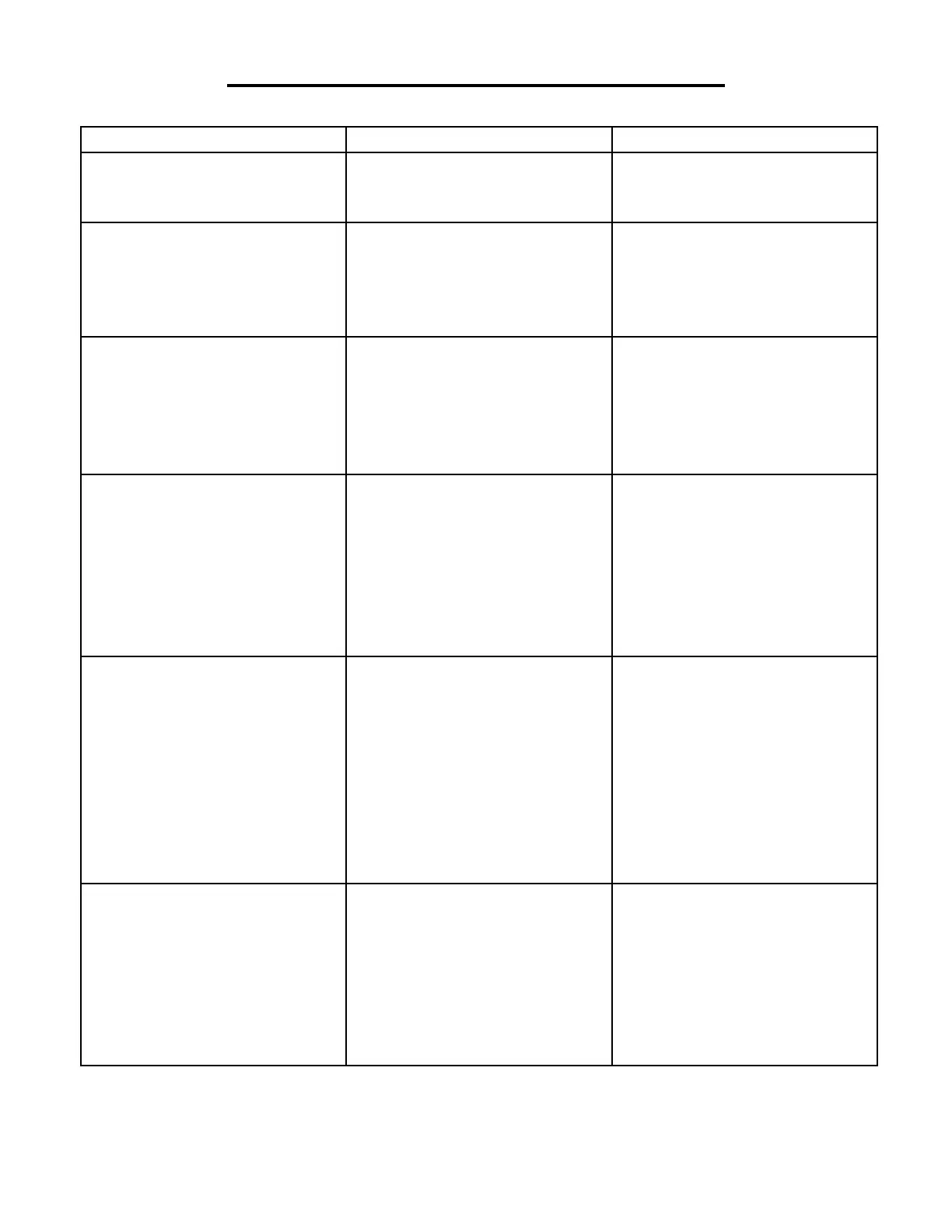

PROBLEM CAUSE SOLUTION

The motor does not work. Defective motor, power cable or

plug.

1. Specialized personnel should

check the machine.

2. Close the safety cover.

Machine stalls or is underpow-

ered.

1. Wrong blade for the workpiece

material (metal).

2. Feed rate too fast for task.

3. V-belt is slipping.

1. Use a blade with correct prop-

erties for your type of cutting.

2. Decrease the feed rate.

3. Replace bad v-belt and re-

tension.

Machine has vibration or noisy

operation.

1. V-belt is slapping the belt cover.

2. V-belt is worn or loose.

3. Pulley is loose.

1. Inspect belt cover for proper

installation.

2. Inspect/replace belt with a new

one.

3. Realign/replace shaft, pulley,

setscrew and key as required.

Teeth are ripping from the blade. 1. The feed pressure is too heavy

and the blade speed is too slow;

or the blade TPI is too coarse for

the workpiece.

2. The workpiece is vibrating in

the vise.

3. The blade gullets are loading

up with chips.

1. Decrease the feed pressure or

choose the proper blade.

2. Re-clamp the workpiece in the

vise and use a jig if required.

3. Use a coarser-tooth blade.

Inaccurate cut squaring 1. Excessive cutting pressure.

2. Incorrect blade tooth in rela-

tion to the workpiece.

3. Incorrect adjustment of the

sliding blade guide.

4. Incorrect cutting speed in rela-

tion to work piece.

5. The workpiece is wrongly posi-

tioned in the vise.

6. Poor blade tension.

1. Decrease the cutting pressure.

2. Choose the proper blade for

the given workpiece.

3. Check the blade guide adjust-

ment.

4. Adjust to the correct cutting

speed.

5. Check workpiece positioning

and clamping in the vise.

6. Check the blade tension.

The blade tends to protrude from

the guide.

1. Excessive blade tension.

2. Incorrect eccentric blade guide

adjustment.

3. The blade slips on the pulleys,

due to the oil or grease required

for cutting operations.

1. Check blade tension.

2. Check eccentric blade guide

adjustment.

3. Never use any type of lubri-

cant or coolant for the cutting

operations; specialized personnel

should check and replace the pul-

leys if necessary.

TROUBLESHOOTING

Loading...

Loading...