COOLING

SYSTEM

HEAT

EXCHANGER

Cool

raw

water

flows

through

the

inner tubes of

the

heat

exchanger.

As

the

en~e.

coolant passes around these

tubes

!11e

heat

of the internal

engme

is

conducted to the

raw

water

which

.

is

then

pumped

into

the

exhaust

system

and

discharged.

The

engine

coolant

(now

cooled)

flows

back though the

engine

and

the

circuit

repeats

itself.

The

engine coolant

and

raw

water

are

independent of

each

other;

this

keeps

the

engine's water passages clean

from

the

hmnful deposits

found

in

raw

water.

NOTE:

Operating in silty arul/or.tropical waters

may

require

that a heat exchanger cleaning be peeformed

more

often then

every

1000

hours.

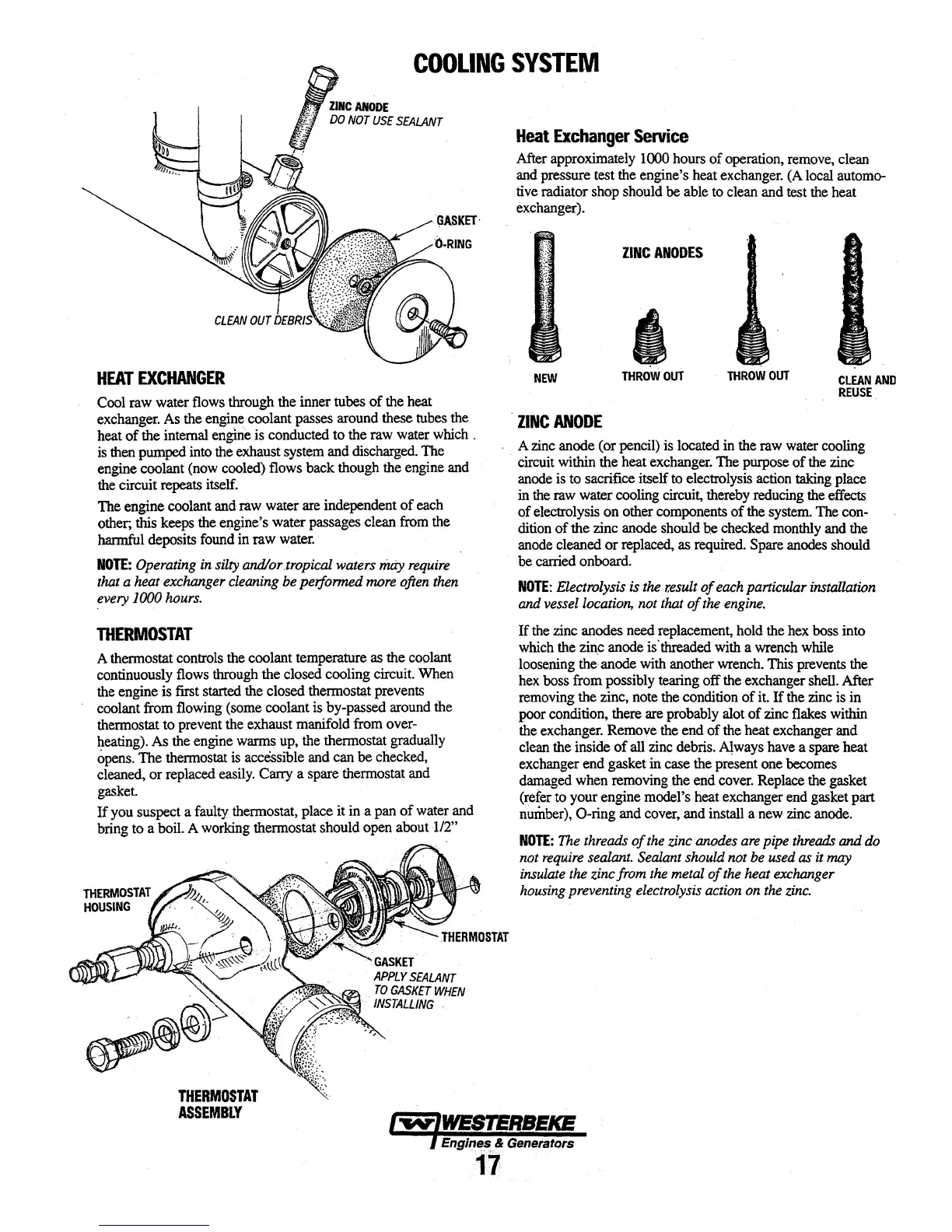

THERMOSTAT

A thermostat controls

the

coolant temperature

as

the

coolant

continuously

flows

through

the closed cooling circuit.

When

the

engine

is

first

started

the

closed

thermostat prevents .

coolant

from

flowing

(some

coolant

is

by-passed

around

the

thennostat to

prevent

the

.exhaust

manifold

from

over-

heating).

As

the

engine

warms

up,

the

thennostat

gradually

opens.

The

thermostat

is

accessible

and

can

be

checked,

cleaned,

or

replaced

easily.

Carry a spare thennostat

and

gasket.

If

you

suspect a

faulty

thermostat,

place it

in

a

pan

of

water

and

bring

to

a

bOil.

A

working

thermostat should

open

about

112"

Heat

Exchanger

Service

After

approximately

1000

hours

of

operation,

remove,

clean

and

pressure test

the

engine's

heat

exchanger.

(A

local

automo-

tive

radiator

shop

should

be

able to

clean

and

test

the

heat

exchanger).

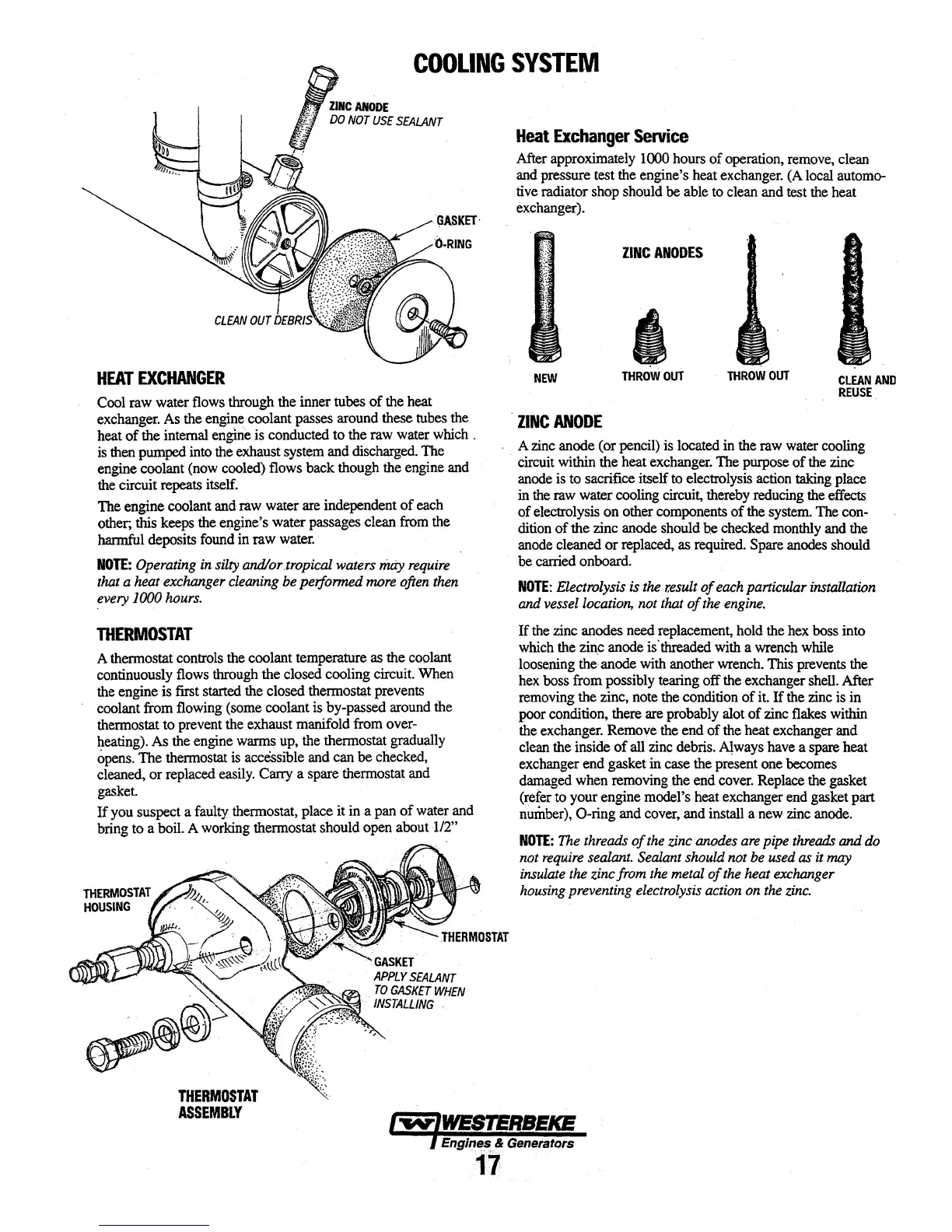

ZINC

ANODES

..

NEW

THROWOUT

ZINC

ANODE

THROWOUT

CLEAN

AND

REUSE.

A

zinc

anode (or pencil) is located

in

the

raw

water

cooling

circuit

within

the heat

exchanger.

The

purpose

of

the

zinc

anode

is

to

sacrifice itself to electrolysis

action

taking

place

in

the

raw

water

cooling

circuit,

thereby

reducing

the

effects

of

electrolysis

on other

components

of

the

system.

The

con-

dition

of the

zinc

anode

should

be

checked

monthly

and

the

anode

cleaned

or

replaced,

as

required.

Spare

anodes

should

be

carried

onboard.

NOTE:

Electrolysis

is

the

r.esult

of

each particular installation

and vessel location, not that

of

the

engine.

If

the

zinc

anodes

need

replacement,

hold

the

hex

boss

into

which

the

zinc

anode

is·

threaded

with

a

wrench

while

loosening

the:

anode

with

another

wrench.

This prevents

the

hex

boss

from

possibly tearing off the exchanger

shell.

After

removing

the zinc, note the condition of it.

If

the

zinc

is

in

poor

condition,

there

are

probably

alot

of

zinc

flakes

within

the

exchanger.

Remove

the end of the heat

exchanger

and

clean

the

inside

of

all

zinc

debris.

Al.ways

have

a

spare

heat

exchanger

end gasket

in

case

the

present one

becomes

damaged

when

removing

the end

cover.

Replace

the gasket

(refer

to

your engine model's

heat

exchanger

end

gasket part

number),

0-ring

and

cover,

and

install

a

new

zinc

anode.

NOTE:

The threads

of

the

zinc anodes are pipe

threads

and do

not

require

sealant. Sealant should not be used as it

may

insulate

the

zinc from

the

metal

of

the

heat exchanger

housing preventing electrolysis action on the

zinc.

THERMOSTAT

ASSEMBLY

IW'IWESTERBEKE

.f Engines & Generators

.

-17

Loading...

Loading...