ENGINE

ADJUSTMENTS

SPARK

PLUGS

The

spark plugs should

be

cleaned and regapped after the

first 50

hour

break-in period, then inspected every 250 hours

thereafter and replaced

as

needed.

AWARNING:

Do

not

remove

the

spark

plugs

while

the

engine

is

hot.

Allow

the

engine

to

cool

before

removing

them.

Spark

plug

gap:

0.031 - :!: 0.0002

in.

(0.8 - 0.05

mm).

Spark

plug

torque:

10

-15

lb-ft

(1.5 - 2.31

kg-m).

NOTE:

Loctite Anti-Seize applied to the threaded portion

of

the

spark plugs

wilt

retard

corrosion,

making future

removal

of

the

spark plugs

easier.

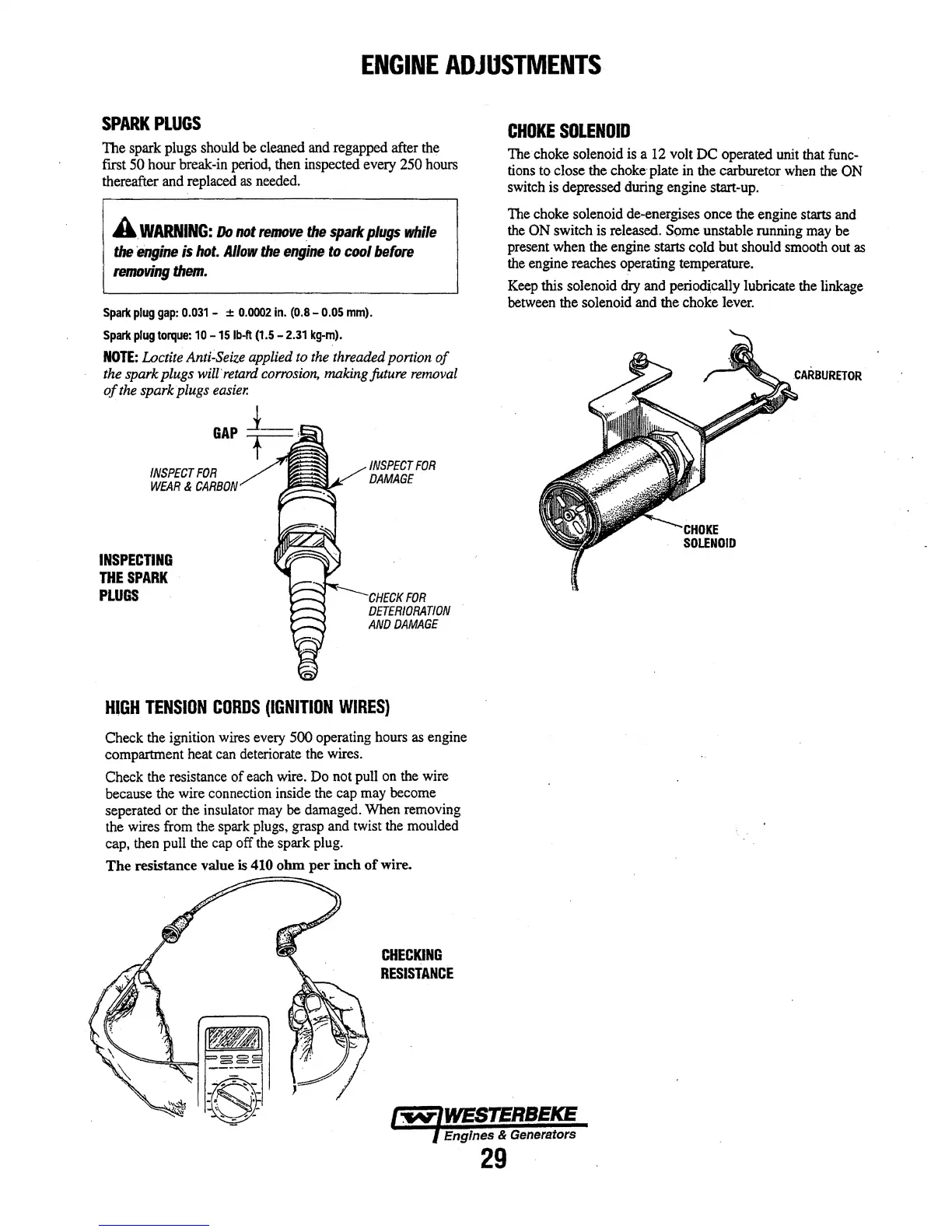

GAP

INSPECT

FOR

WEAR

&

CARBON

INSPECTING

THE

SPARK

PLUGS

INSPECT

FOR

DAMAGE

,______CHECK

FOR

DETERIORATION

AND

DAMAGE

HIGH

TENSION

CORDS

(IGNITION

WIRES}

Check the ignition wires every

500

operating hours

as

engine

compartment heat can deteriorate the wires.

Check the resistance

of

each wire. Do not pull on the wire

because the wire connection inside the cap may become

seperated or the insulator may be damaged. When removing

the wires from the spark plugs, grasp and twist the moulded

cap, then pull the cap off the spark plug.

The

resistance value

is

410

ohm

per

inch

of

wire.

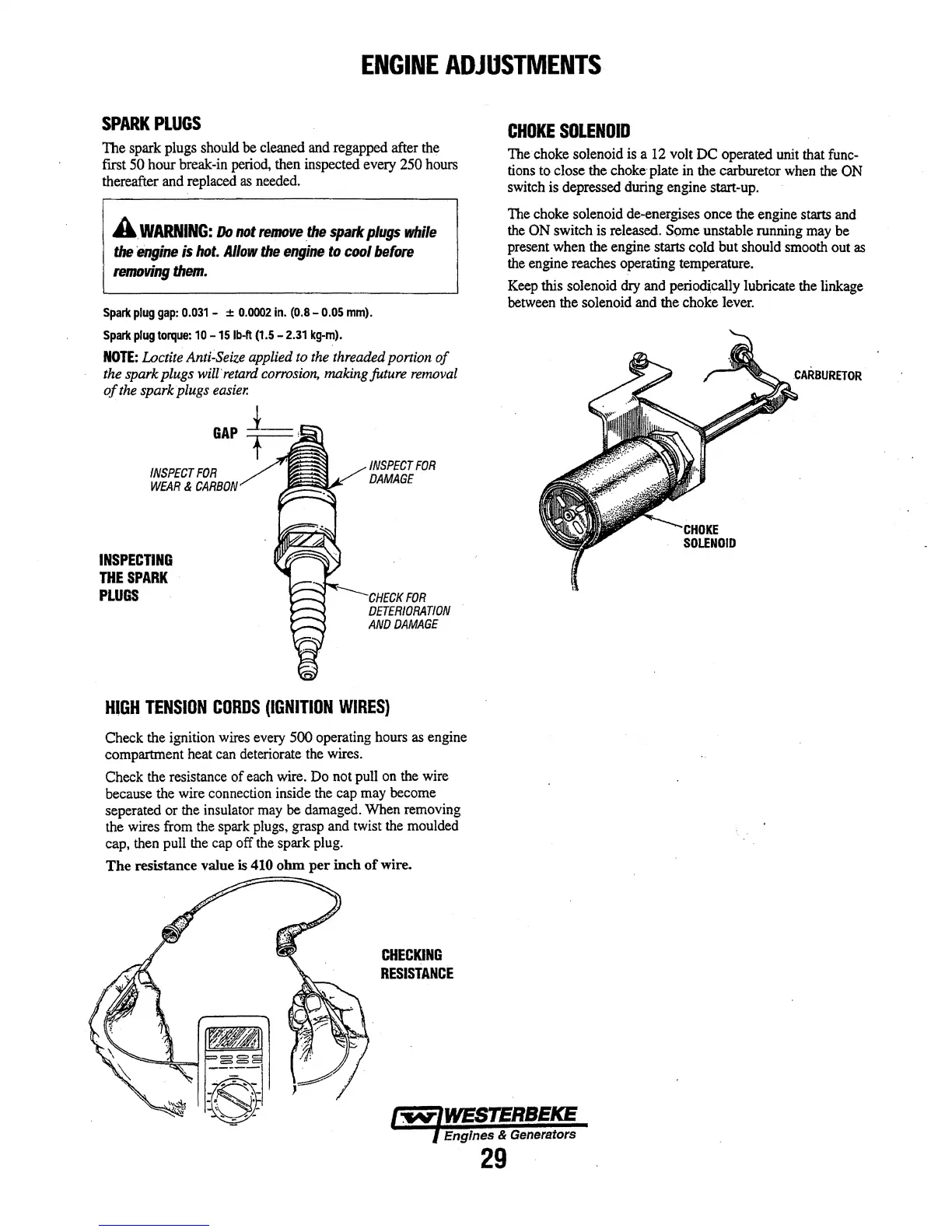

CHECKING

RESISTANCE

CHOKE

SOLENOID

The choke solenoid is a 12 volt

DC

operated unit that func-

tions to close the

choke·plate in the carburetor when the ON

switch is depressed during engine start-up.

The choke solenoid de-energises once the engine starts and

the

ON switch is released.

Some

unstable running may

be

present when the engine starts cold

but

should smooth out

as

the engine reaches operating temperature.

Keep this solenoid dry and periodically lubricate the linkage

between the solenoid and the choke lever.

CARBURETOR

Engines & Generators

29

Loading...

Loading...