Kunststoffschweißtechnik

WIDOS Einsteinstraße 5 Phone +49 (0) 71 52 / 99 39 - 0

W. Dommer Söhne GmbH D-71254 Ditzingen-Heimerdingen Fax +49 (0) 71 52 / 99 39 - 40

info@widos.de Internet: www.widos.de

20.08.14 Working instructions WIDOS 3511 Page 13 of 39

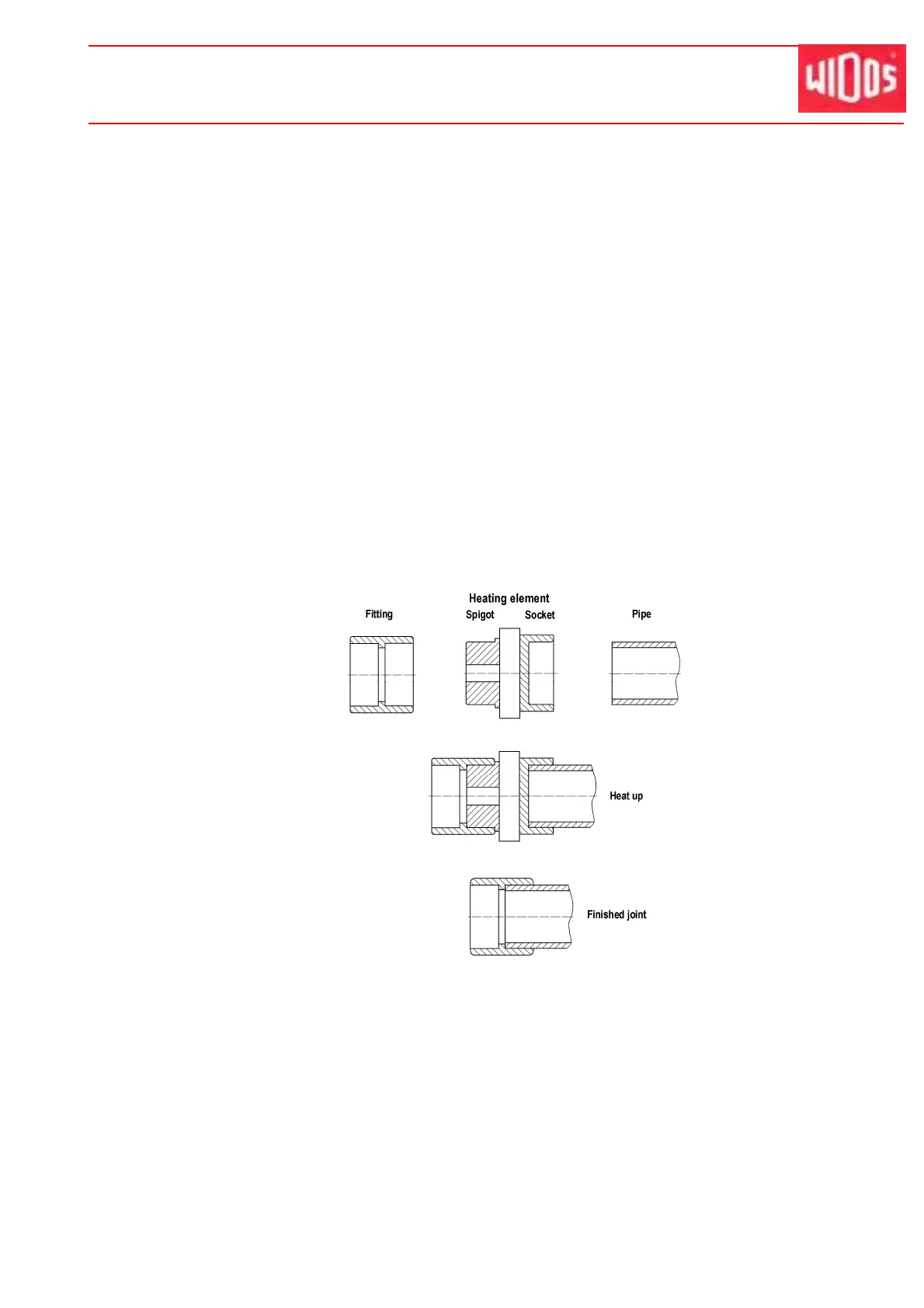

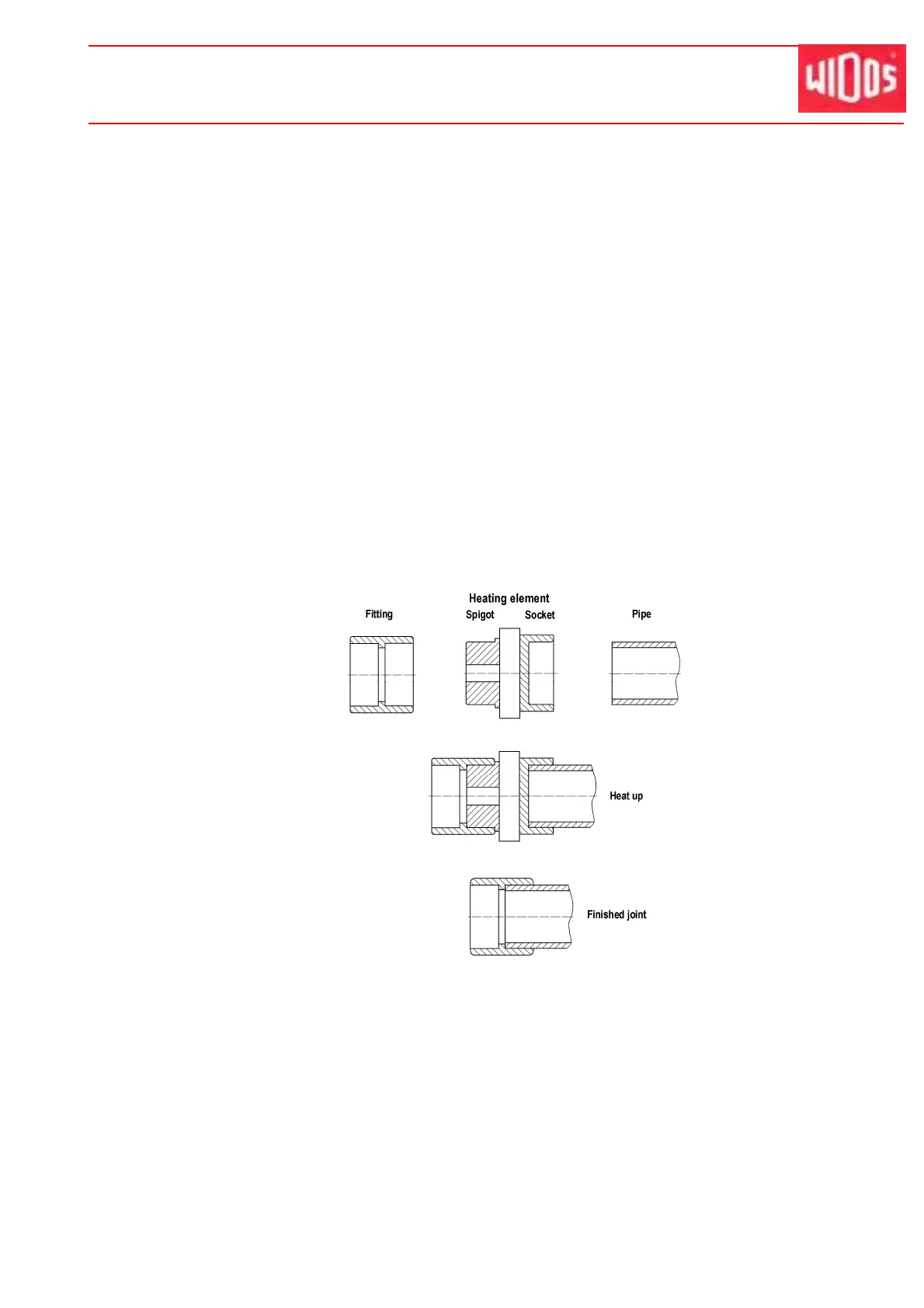

3. Functional description

Basically, the international and national standard specifications are

to be fulfilled.

First of all, the two workpieces to be welded are put into the clamping device, the fitting is

clamped at the stop of the clamping device.

Then the zero offset is effected and the pipe can be clamped in such a way that both

workpieces can be heated up to welding temperature at the same time (heat-up time) with the

help of a socket or spigot-shaped heating element.

After swinging out the heating element (change-over time), the workpieces are joined (cooling

time).

The pipe end, heating element and fitting socket are to match each other in size in such a way

that a joining pressure will build up during joining.

After expiration of the cooling time, the welded joint can be unclamped, the welding process is

finished.

Principle of heating element socket welding

Loading...

Loading...