Gas Supply and Piping (cont.)

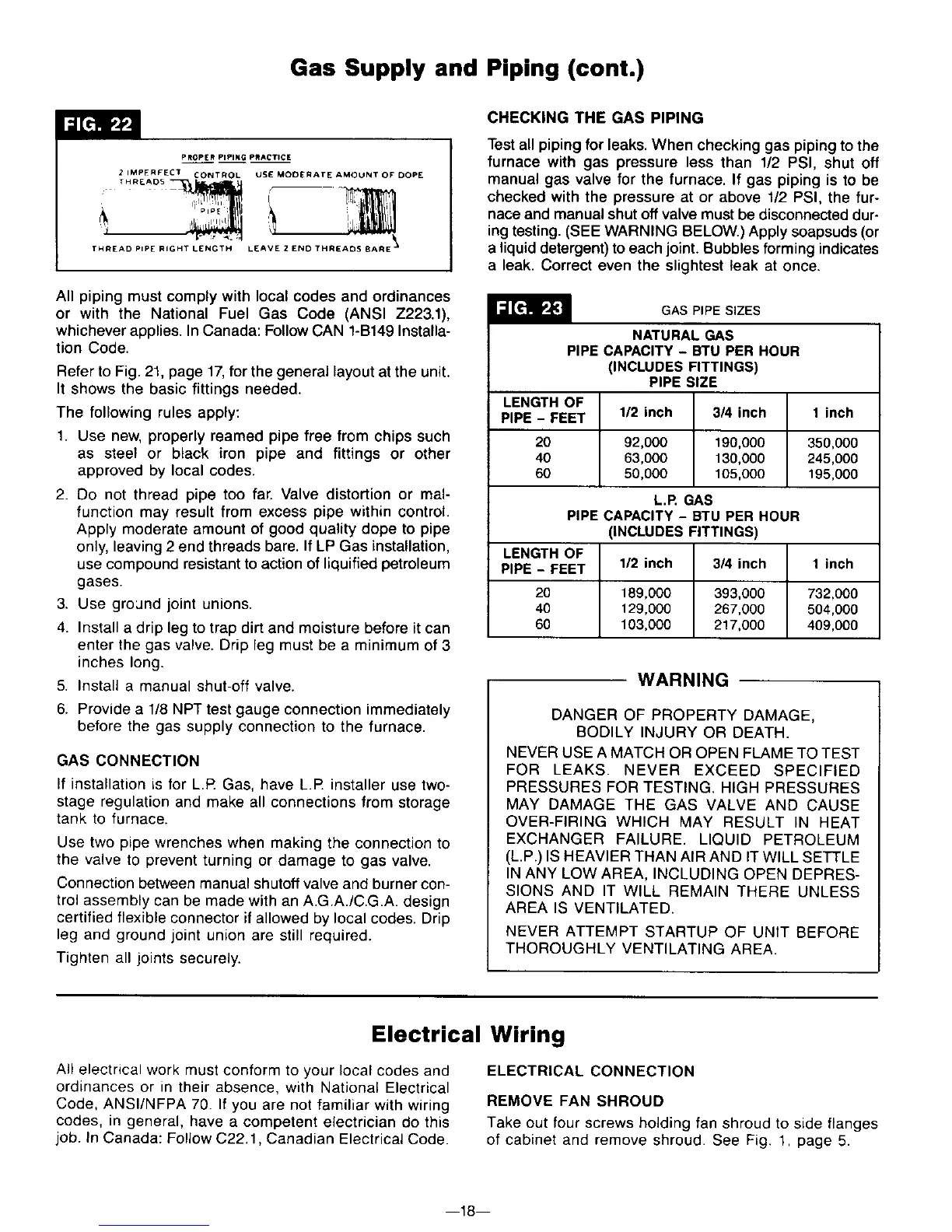

PROPER PIPING PRACTICE

2 IMPERFECT CONTRO L USE MODERATE AMOUNT OF DOPE

THREADS _

THREAD PIPE RIGHT LENGTH LEAVE 2 END THREADS [IARE "

All piping must comply with local codes and ordinances

or with the National Fuel Gas Code (ANSI Z223.1),

whichever applies. In Canada: Follow CAN 1-B149 Installa-

tion Code.

Refer to Fig. 21, page 17,for the general layout at the unit.

It shows the basic fittings needed.

The following rules apply:

1. Use new, properly reamed pipe free from chips such

as steel or black iron pipe and fittings or other

approved by local codes.

2. Do not thread pipe too far. Valve distortion or mal-

function may result from excess pipe within control.

Apply moderate amount of good quality dope to pipe

only, leaving 2 end threads bare. If LP Gas installation,

use compound resistant to action of liquified petroleum

gases.

3. Use ground joint unions.

4. Install a drip leg to trap dirt and moisture before it can

enter the gas valve. Drip leg must be a minimum of 3

inches long.

5. Install a manual shut-off valve.

6. Provide a 1/8 NPT test gauge connection immediately

before the gas supply connection to the furnace.

GAS CONNECTION

If installation is for L.R Gas, have L.R installer use two-

stage regulation and make all connections from storage

tank to furnace.

Use two pipe wrenches when making the connection to

the valve to prevent turning or damage to gas valve.

Connection between manual shutoff valve and burner con-

trol assembly can be made with an A.G.A./C.G.A. design

certified flexible connector if allowed by local codes. Drip

leg and ground joint union are still required.

Tighten all joints securely.

CHECKING THE GAS PIPING

Test all piping for leaks. When checking gas piping to the

furnace with gas pressure less than 1/2 PSI, shut off

manual gas valve for the furnace. If gas piping is to be

checked with the pressure at or above 1/2 PSI, the fur-

nace and manual shut off valve must be disconnected dur-

ing testing. (SEE WARNING BELOW.) Apply soapsuds (or

a liquid detergent) to each joint. Bubbles forming indicates

a leak. Correct even the slightest leak at once.

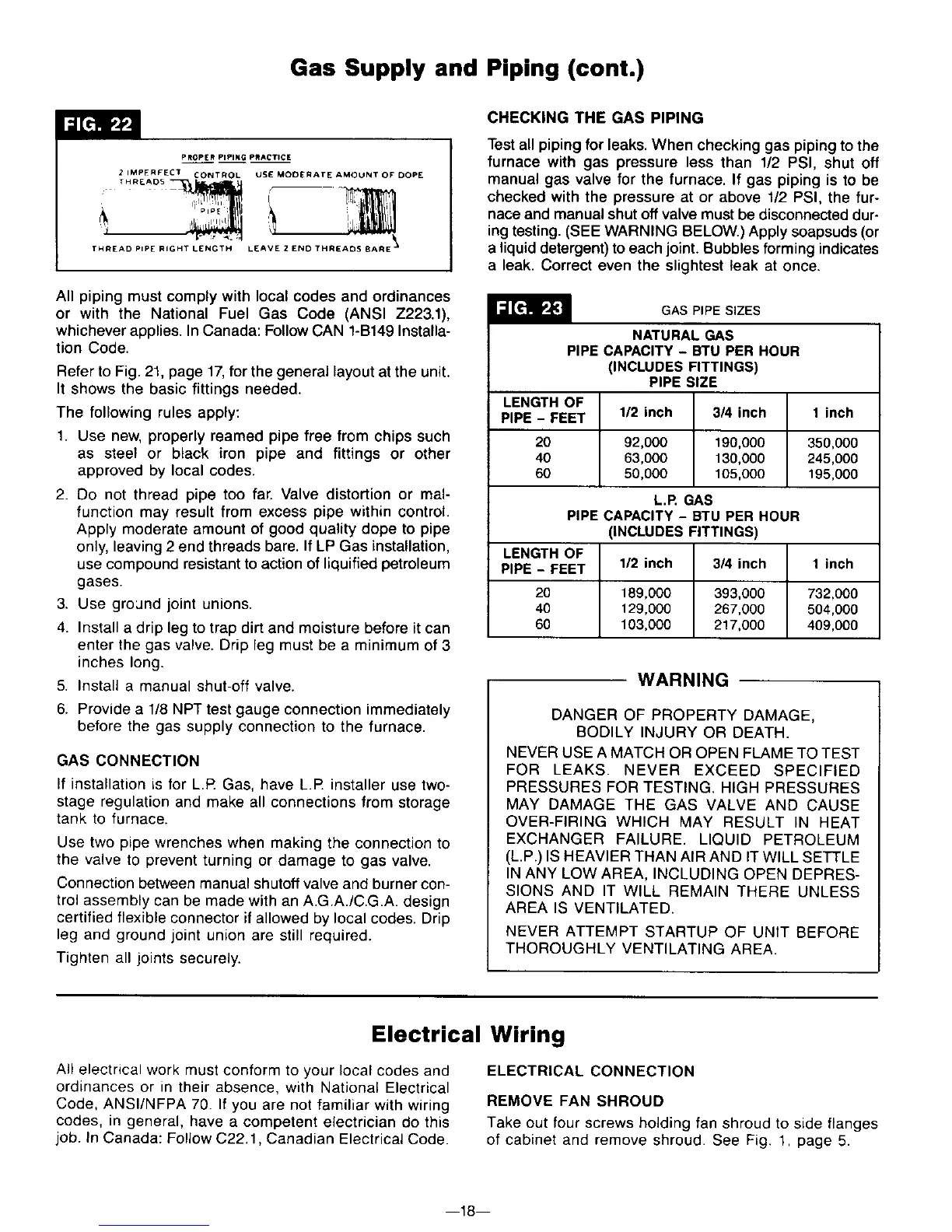

GAS PIPE SIZES

NATURAL GAS

PIPE CAPACITY - BTU PER HOUR

(INCLUDES FITTINGS)

PIPE SIZE

LENGTH OF

PIPE - FEET 1/2 inch 3/4 inch 1 inch

20 92,000 190,000 350,000

40 63,000 130,000 245,000

60 50,000 105,000 195,000

L.P. GAS

PIPE CAPACITY - BTU PER HOUR

(INCLUDES FITTINGS)

LENGTH OF

PIPE - FEET 1/2 inch 3/4 inch 1 inch

20 189,000 393,000 732,000

40 129,000 267,000 504,000

60 103,000 217,000 409,000

WARNING

DANGER OF PROPERTY DAMAGE,

BODILY INJURY OR DEATH.

NEVER USE A MATCH OR OPEN FLAME TO TEST

FOR LEAKS. NEVER EXCEED SPECIFIED

PRESSURES FOR TESTING. HIGH PRESSURES

MAY DAMAGE THE GAS VALVE AND CAUSE

OVER-FIRING WHICH MAY RESULT IN HEAT

EXCHANGER FAILURE. LIQUID PETROLEUM

(L.P.) IS HEAVIER THAN AIR AND IT WILL SETTLE

IN ANY LOW AREA, INCLUDING OPEN DEPRES-

SIONS AND IT WILL REMAIN THERE UNLESS

AREA IS VENTILATED.

NEVER ATTEMPT STARTUP OF UNIT BEFORE

THOROUGHLY VENTILATING AREA.

Electrical Wiring

All electrical work must conform to your local codes and

ordinances or in their absence, with National Electrical

Code, ANSI/NFPA 70. If you are not familiar with wiring

codes, in general, have a competent electrician do this

job. In Canada: Follow C22.1, Canadian Electrical Code.

ELECTRICAL CONNECTION

REMOVE FAN SHROUD

Take out four screws holding fan shroud to side flanges

of cabinet and remove shroud. See Fig. 1, page 5.

m18m

Loading...

Loading...