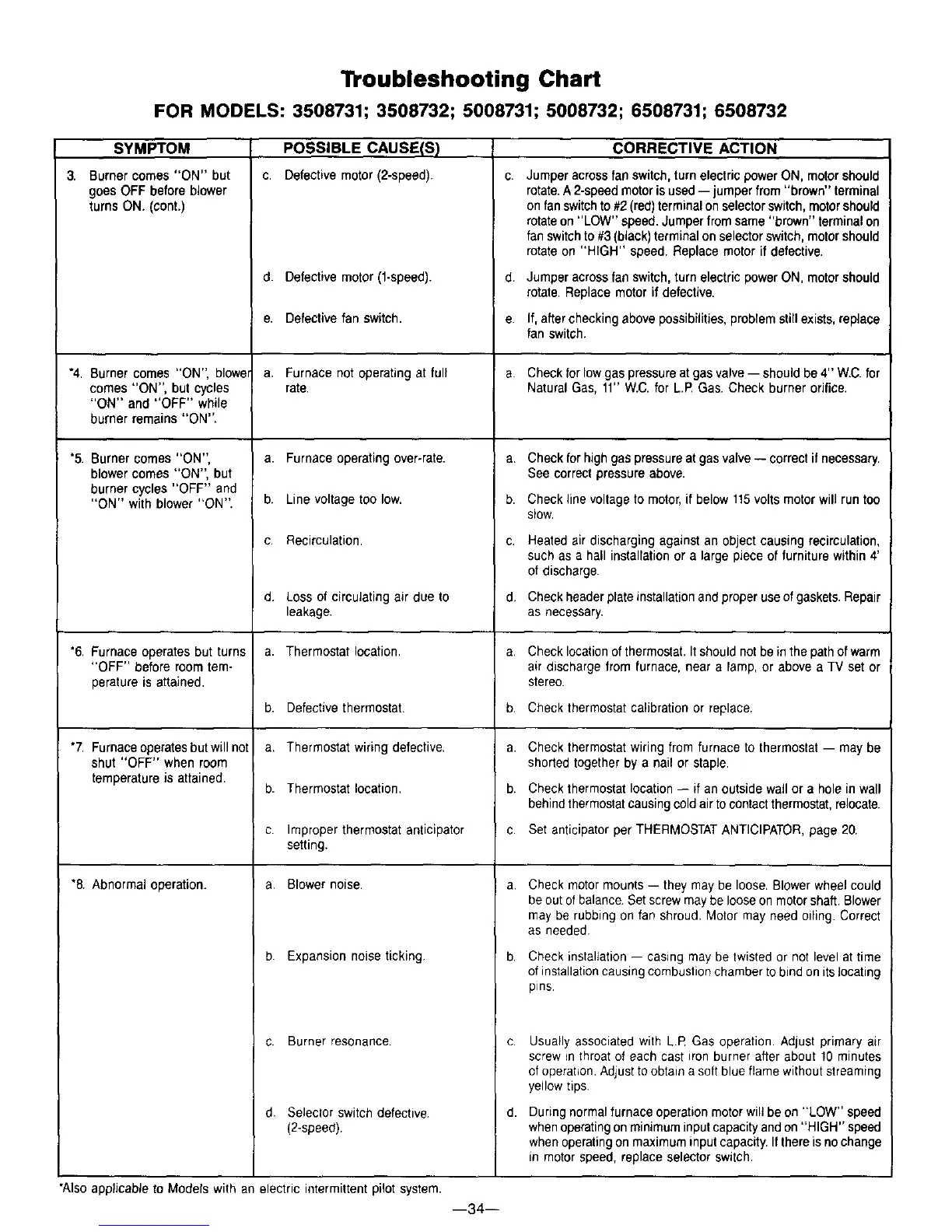

Troubleshooting Chart

FOR MODELS: 3508731; 3508732; 5008731; 5008732; 6508731; 6508732

SYMPTOM

3. Burner comes "ON" but

goesOFF before blower

turns ON. (cont.)

POSSIBLE CAUSE(S)

c, Defectivemotor(2-speed).

d. Defective motor (1-speed).

e. Defective fan switch.

a. Furnace not operating at full

rate.

a. Furnace operating over-rate.

b. Line voltage too low.

c. Recirculation.

*4. Burnercomes "ON", blowe

comes "ON", but cycles

"ON" and "OFF" while

burner remains "ON".

*5. Burner comes "ON",

blower comes "ON", but

burner cycles "OFF" and

"ON" with blower "ON".

"6. Furnace operates but turns

"OFF" before room tem-

perature is attained.

*7. Furnace operatesbut will not

shut "OFF" when room

temperature is attained.

*8. Abnormal operation.

d. Loss of circulating air due to

leakage.

a. Thermostat location.

b. Defective thermostat.

a. Thermostat wiring defective.

b. Thermostat location,

c Improper thermostat anticipator

setting.

a. Blower noise.

b. Expansion noise ticking,

c. Burnerresonance.

d. Seleclor switch defective.

(2-speed).

C.

d.

e.

a.

a.

b.

C,

d,

a.

b.

a.

b.

C.

CORRECTIVE ACTION

Jumperacross fan switch,turnelectric powerON, motor should

rotate.A2-speedmotor is used-- jumper from "brown" terminal

onfanswitchto #2(red)terminalonselectorswitch, motorshould

rotateon"LOW" speed. Jumperfrom same"brown" terminalon

fan switchto#3 (black) terminalonselectorswitch, motorshould

rotateon "HIGH" speed. Replacemotor if defective.

Jumper across fan switch, turn electric power ON, motor should

rotate. Replace motor if defective.

If, after checkingabove possibilities, problem still exists, replace

fan switch.

Check for low gas pressure atgas valve -- should be 4" W.C.for

Natural Gas, 11" W.C. for L.R Gas. Check burner orifice.

Check for high gaspressure at gas valve-- correctif necessary.

See correct pressure above.

Check line voltage to motor, if below 115volts motor will run too

s_ow.

Heated air discharging against an object causing recirculation,

such as a hall installation or a large piece of furniture within 4'

of discharge.

Checkheaderplate installation and proper use ofgaskets.Repair

as necessary.

Checklocation of thermostat. It should not be in the path ofwarm

air discharge from furnace, near a lamp,or above a TV set or

stereo.

Check thermostatcalibration or replace.

Check thermostat wiringfrom furnace to thermostat -- may be

shorted together by a nail or staple.

Check thermostat location -- if an outside wall or a hole in wall

behind thermostatcausingcold air tocontactthermostat, relocate.

Set anticipator per THERMOSTATANTICIPATOR,page 20.

Check motor mounts -- they may be loose. Blower wheelcould

be out ofbalance Setscrew may be looseon motor shaft. Blower

may be rubbing on fan shroud. Motor may need oiling. Correct

as needed.

Check installation -- casing may be twisted or not level at time

of installation causing combustion chamber to bind on its locating

pros

Usually associated with L.R Gas operation. Adjust primary air

screw =nthroatof each cast iron burner after about 10 minutes

of operation. Adjust to obtain a soft blue flame without streaming

yellow tips,

During normal furnace operation motor will be on "LOW" speed

when operatingon minimum inputcapacity and on"HIGH" speed

whenoperating on maximum input capacity. Ifthere is no change

in motor speed, replace selector switch.

"Also applicableto Models with an electric intermittent pilotsystem.

--34--

Loading...

Loading...