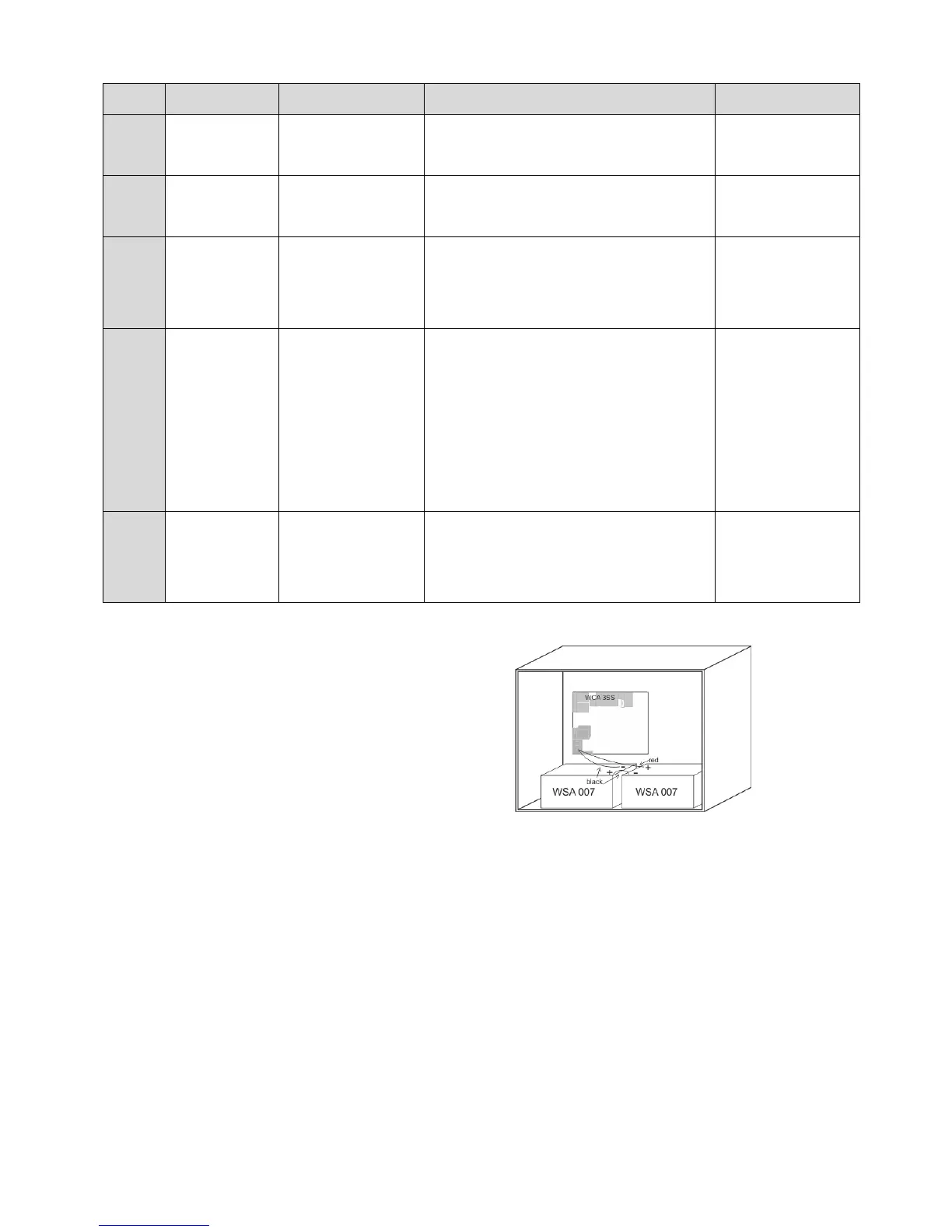

Re-activation of run

time limitation

(OPEN)

ON: If DIP switch 2.1 - 2.3 is activated, the run

time limitation can be reactivated.

OFF: normal

If DIP switch 2.1 - 2.3

is not activated, there

is no function on DIP

switch 2.4.

20A actuator output

on X1

ON: actuator output X1 is 20A and actuator

output X2 is 10A.

OFF: both actuator outputs (X1 & X2) are 10A

Type of motor line

cable monitoring.

ON: simple monitoring. Short circuit between

all wires or cable break is detected.

OFF: Full monitoring. Short circuit between

any of the wires and break of any of the wires

is detected.

Deactivate grace

timer (manual

operation after an

safety command)

ON: Deactivate grace timer

OFF: Use standard grace timer 30 sec.

(default)

The grace timer is a safety feature that gives

the user the possibility to interfere with

automatic (non smoke) safety commands for

30 sec. After the 30 sec. has ran out the

actuator will return to the automatic position.

Smoke commands (Alarm/Reset) always has

first priority.

Disable low

stand-by power

Disalbes low power

consumption

ON: Low power mode is disable. Main power

supply is kept on.

OFF: Low power mode is enabled. Main power

shuts off, but turns on every 90sec due to

cable monitoring.

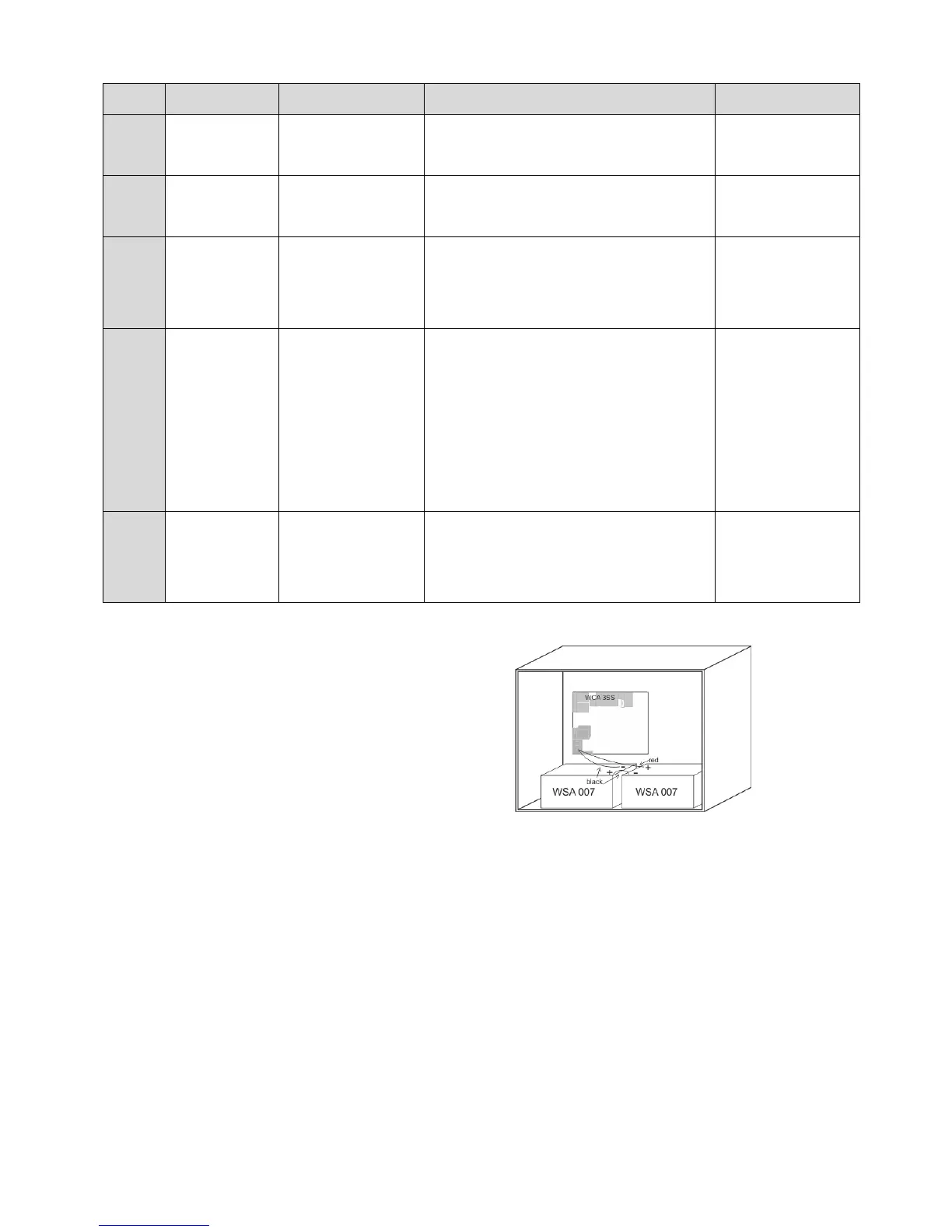

Connect 2 pcs. back-up batteries type

WSC 007 for WSC 310 and type WSA 012

for WSC 320.

See section 17 “Maintenance” for further

information.

Example of WSC 310 panel with back–up batteries.

13 Configuration of panel

The smoke panel is configured by pressing the two keys ”↑” and ”↓” on the main card, at the same time for 5-10 seconds.

The smoke panel must be configured

- After re-installation, changes, or change of actuators

- When / if MotorLink

®

actuators are connected

- If the cables have been moved

- When components are removed from the panel

- If there has been a fault on the WSK-Link™. Error blink sequence 6, see section 14.

Note, during reconfiguration both actuator outputs can be activated in both directions.

If the yellow diode on the main card blinks after a configuration, an error has occurred in the configuration, see section “Fault

detection via LED” for identification of errors.

13.1 Motor lines – motor groups – smoke zones

All the components connected to the Standard panel are automatically assigned to groups and zones:

- motor lines are assigned to motor groups

- motor groups are assigned to smoke zones

- break glass units and smoke detectors are assigned to smoke zones

Loading...

Loading...