24

Example of an error message

”7 blinks – 1sec. pause – 2 blinks – 1 sec. pause – 1 blinks”.

1. There is an error on a local input

2. The error is on input X10.5, to which a rain sensor might be connected

3. The error is due to no connection to the sensor.

If there are more errors on the panel simultaneously, they are shown with priority, i.e. the error message for the most critical error is

shown first and repeated until rectified. Then the error message number 2 is shown and repeated as well until the error is rectified

etc.

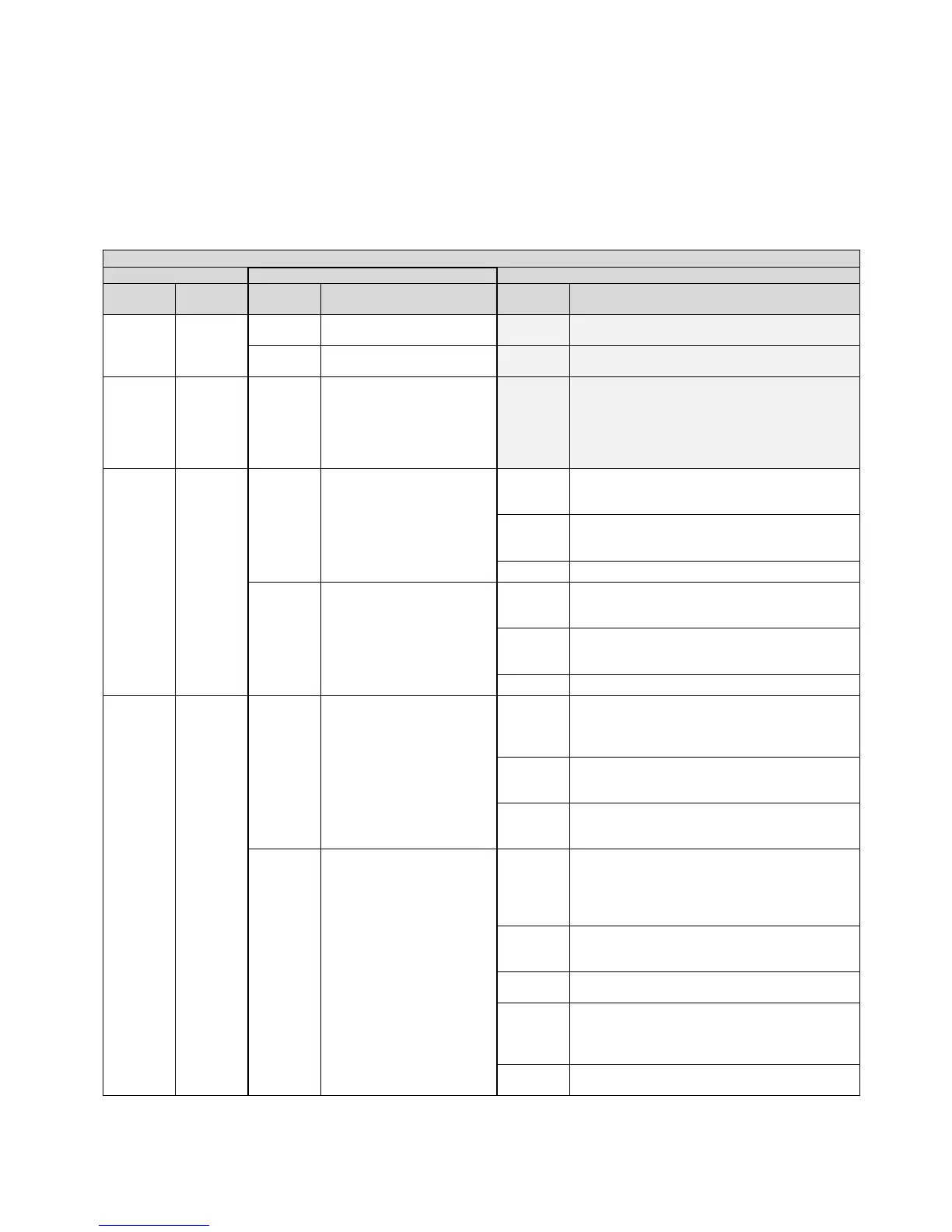

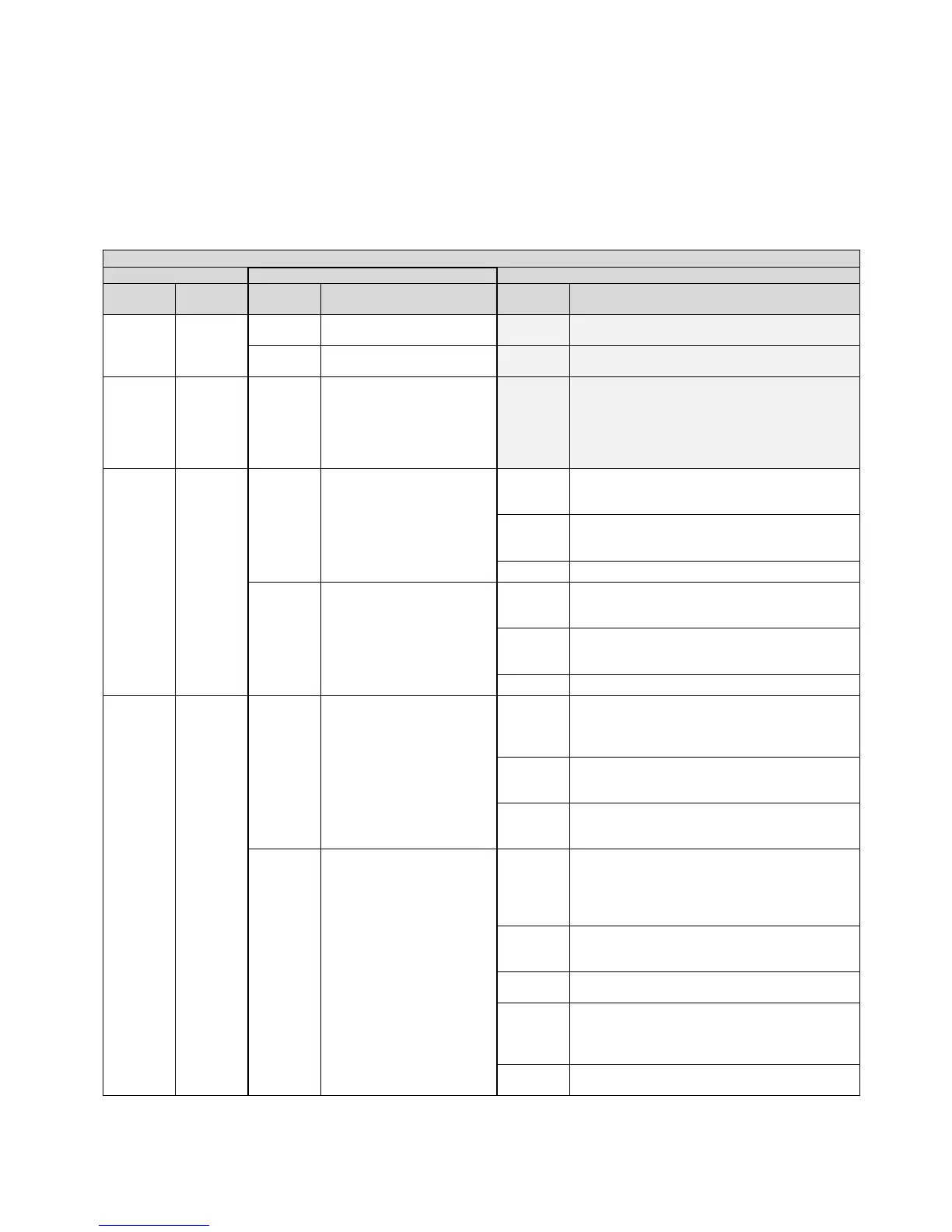

Below table, list the most common errors.

Internal error (Watchdog

reset)

Internal error (Program

CRC)

Max temp. in the panel has

been exceeded – re-

configure and check the

panel, see section 13 for

re-configuration of the

smoke panel

Actuator configuration – check the actuators,

check the configuration, when using ±24V

standard actuators check the termination

Expected number of actuators, the found and

expected number of MotorLink

®

actuators does

not match – check actuator connections

Actuator configuration – check the actuators,

check the configuration, when using ±24V

standard actuators check the termination

Expected number of actuators, the found and

expected number of MotorLink

®

actuators does

not match – check actuator connections

Closed ring – the standard version does not

allow break glass units connected in a closed

ring, check connection of break glass units and

disconnect the ring and re-configure

Problem on X5 (break glass unit) –

communication with the break glass unit

cannot be established

Problem on X6 (break glass unit) –

communication with the break glass unit

cannot be established

Problem (short circuit, cable problem or

termination) with break glass unit #2

connected to a break glass unit– check

connection of break glass unit and termination

smoke detector input

Slave panel – the standard version does not

allow connection of a slave panel. Remove the

slave panel and re-configure

Offline break glass unit, one or more break

glass are offline – check and re-configure

Break glass unit sensor (smoke detector

connected to break glass unit) – check

connection between break glass unit, sensor

and end-module (termination)

The break glass unit version is too old – break

glass units must be renewed

Loading...

Loading...