Maintenance

5556−1/A1

RT-flex58T-E

Winterthur Gas & Diesel Ltd.

7/ 10

4. Assembling of a fuel pump

4.1 Preparation

⇒ Clean all parts and check their condition.

Damaged parts must be replaced.

⇒ Check the lubricating oil bores in the housings and in pump cylinder 33 for free

passage using compressed air.

⇒ Replace all O-rings and rod seal rings.

K

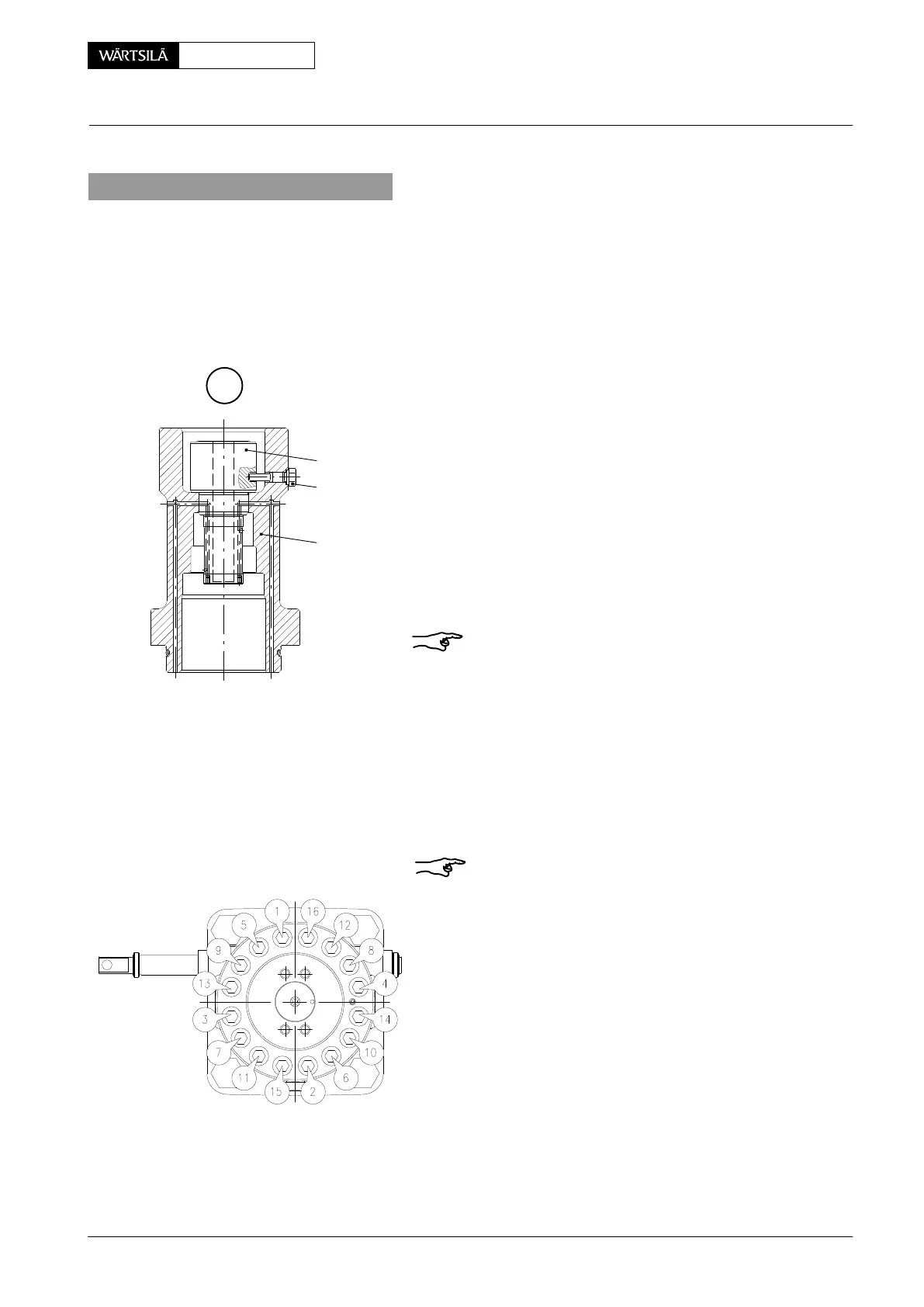

4.2 Fitting the pump cylinder

⇒ Fasten upper housing 5 in vertical position onto a

work bench.

⇒ Carefully fit pump cylinder 33, aligning the groove in

the pump cylinder precisely with the bore provided

for holding screw 32 in the upper housing.

⇒ Screw in and tighten the holding screw together with

the Cu-ring.

Remark: There must be a clearance between holding

screw 32 and the groove base!

33

32

5

008.654/00

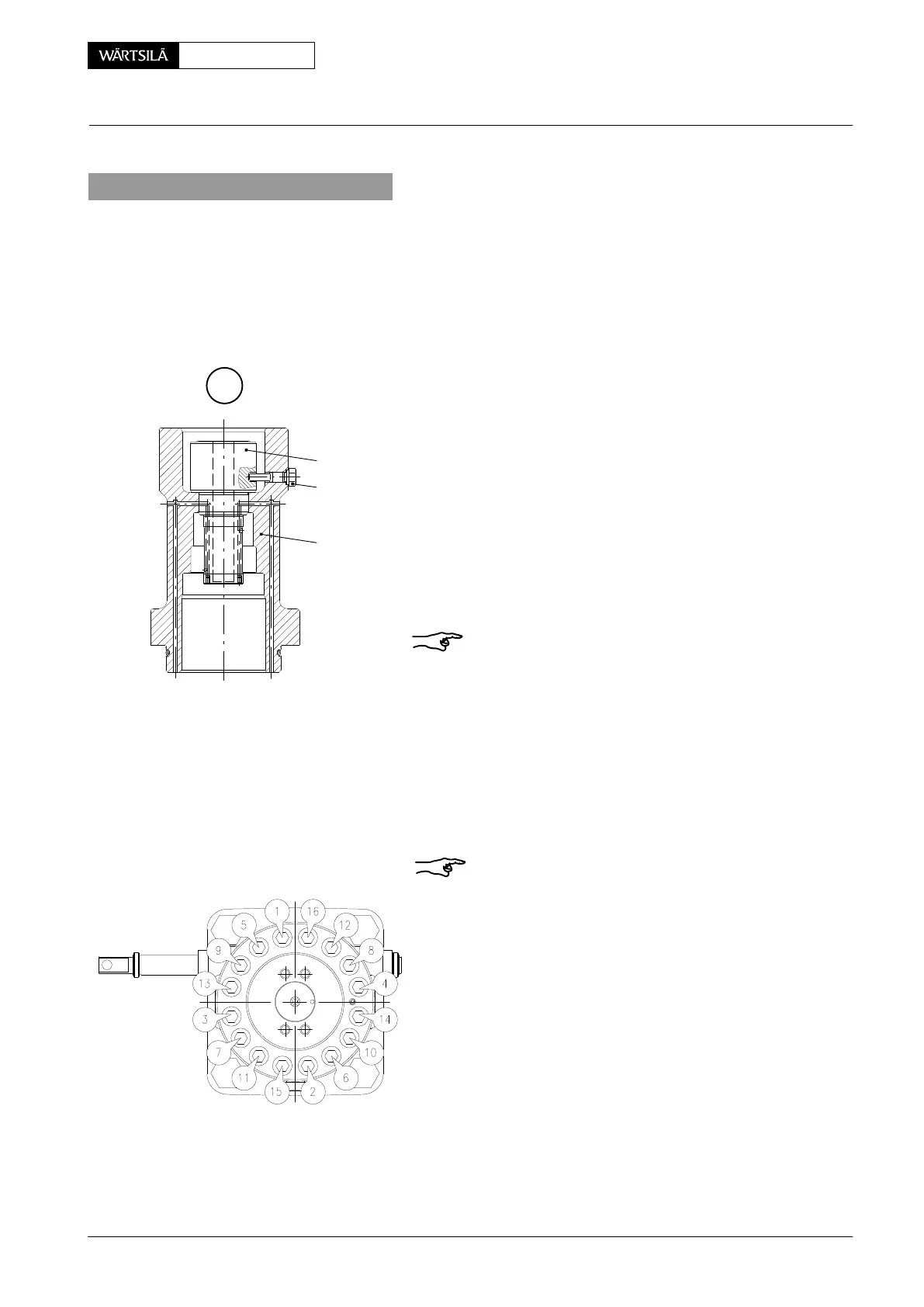

4.3 Fitting the pump cover

Remark: Thoroughly check the joint faces for cleanness

when fitting the valve block and the pump cover (Fig. ’I’).

⇒ Fit valve block 29 with the mounted and lubricated

O-rings 39 in upper housing 5. Then fit valve body

30 and compression spring 31 in the valve block.

⇒ Fit intermediate disc 34 with circlip 35 in the pump

cover.

⇒ Fit pump cover 4.

⇒ Apply Never-Seez NSBT-8 to the threads of the Al-

len screws 28. Tighten them: 1

ST

step HAND

TIGHT, 2

ND

step 40 Nm, 3

RD

step 80 Nm and 4

TH

step with 115 Nm providing the required sequence

for every step.

TIGHTENING

SEQUENCE

2013

Fuel Pump: Dismantling and Assembling

Loading...

Loading...