Maintenance8733−1/A2

RT-flex58T-E

Winterthur Gas & Diesel Ltd.

2/ 3

3. Sealing Faces − Grind

To get a clean and smooth finish on the pipe procedure

as follows:

⇒ Do a check of the O-rings 11−14, Fig.’ E’. If the

O-rings are unserviceable, discard them.

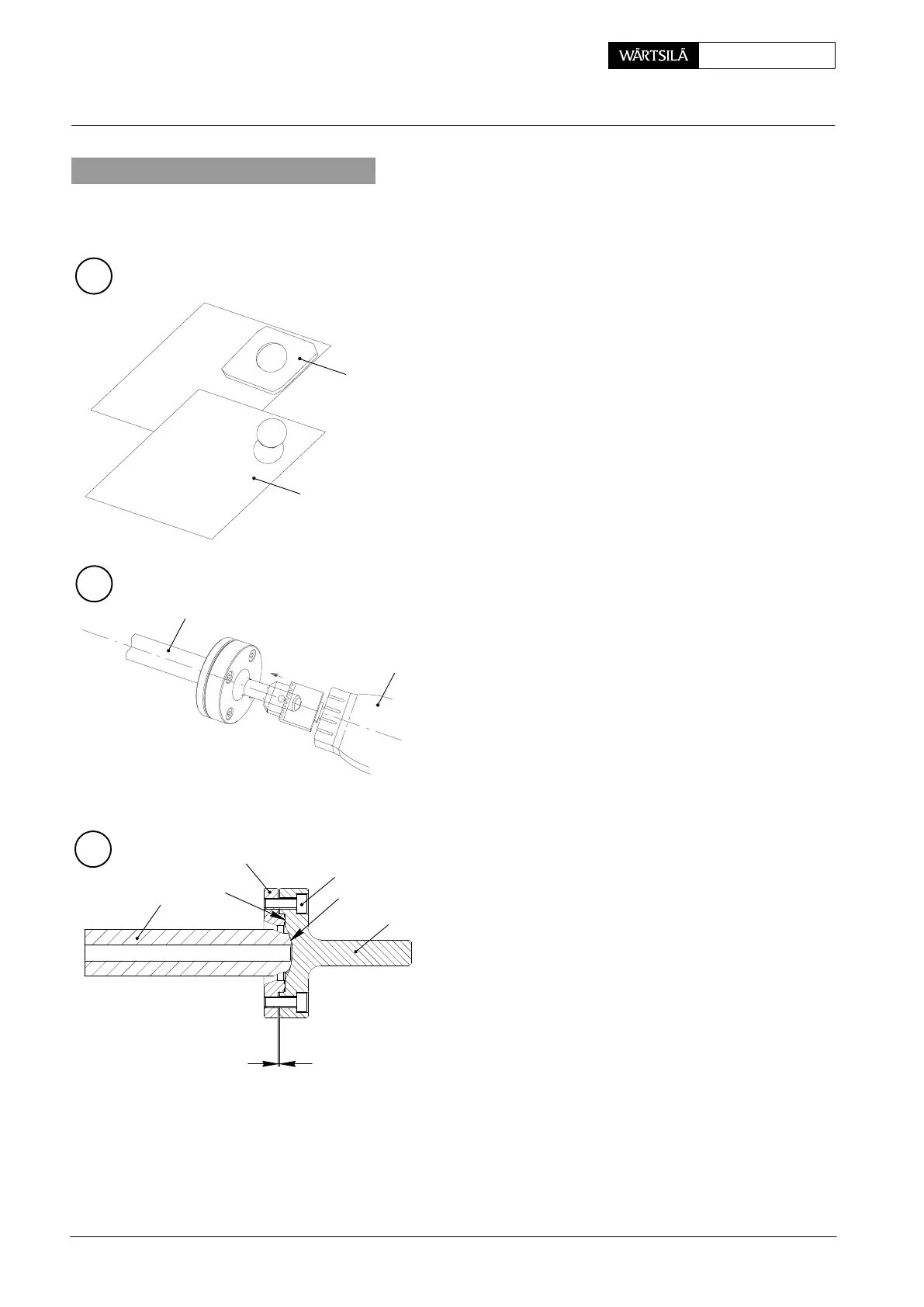

⇒ Put the stencil 94871A on the back of emery cloth

’EC’.

⇒ Use a pointed pencil or a ball pen to sign the inner

contour.

D Use the grade of the emery cloth according to

amount of metal you want to grind.

⇒ Cut out accurately the singed contour.

⇒ Shape the cut emery cloth to cone. Make sure that

the grained surface of the emery cloth shows to in.

⇒ Loosen and remove the four screws T2, Fig.’D’.

⇒ Apply Molyslip Copaslip paste to the threads and

contact surface of the four crews T2.

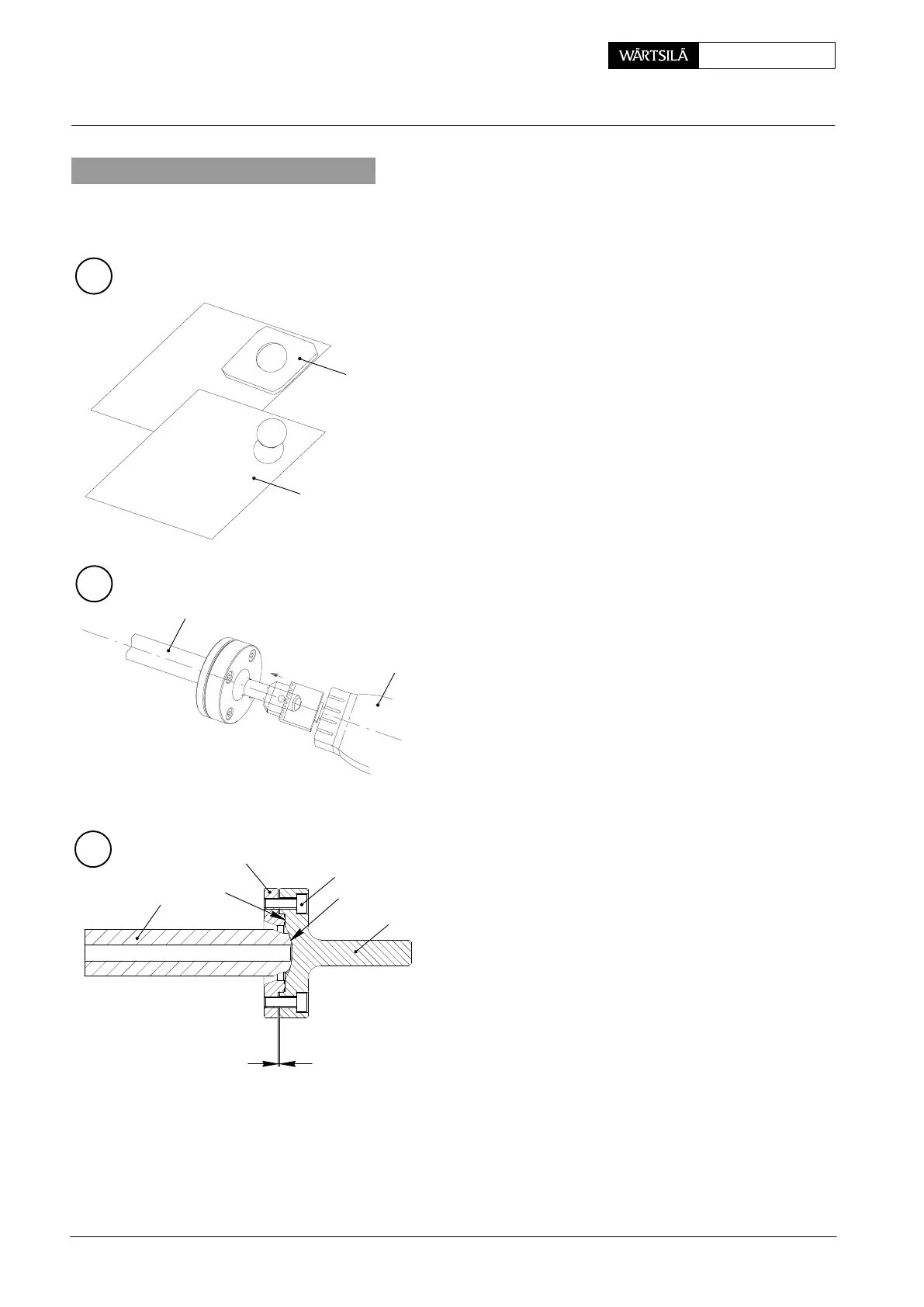

⇒ Put the emery cloth ’EC’ between the regrinding

device 94871 and the flange T1.

Note: Make sure that the grained surface of the emery

cloth shows to the flange T1.

⇒ Push the emery cloth ’EC’ in the spherical shape of

the regrinding device 94871.

⇒ Torque symmetrically the four screws T2 to 2 Nm.

⇒ Install the HP injection pipe 4 in a vice, as vertically

as possible.

⇒ Adjust the speed of the hand drill between 200 and

500 rpm.

⇒ Put the hand drill with the regrinding device 94871

exactly in line on the HP injection pipe as shown in

Fig. ’C’ and start grinding with a slight pressure.

⇒ Check if the grinding circles are concentric around

the bore of the pipe and remove the grinding swarf

from the tool.

⇒ Do the grinding steps few times. For each step use a

finer emery cloth ’EC’. For the last grinding step, use

a polishing cloth.

⇒ Remove the regrinding device 94871 from the HP

injection pipe 4.

⇒ Clean the HP injection pipe 4.

⇒ If necessary, put the new O-rings 11−14, see Fig.

’E’.

⇒ Check the quality of the sealing face ’SF’ and if ne-

cessary use the new emery cloth ’EC’ to repeat the

grinding procedure.

Note: If there are a big notches, the pipe has to be

shortened.

⇒ If necessary, do steps above for the other HP injec-

tion

i

es.

B

WCH02726

94871A

EC

C

D

EC

SF

T2

94871

T1

HD

4

4

min.0.5 mm

2014−07

HP Pipe to Injection Valve: Removal, Grinding and Installation

Loading...

Loading...