Maintenance

8733−1/A2

RT-flex58T-E

Winterthur Gas & Diesel Ltd.

3/ 3

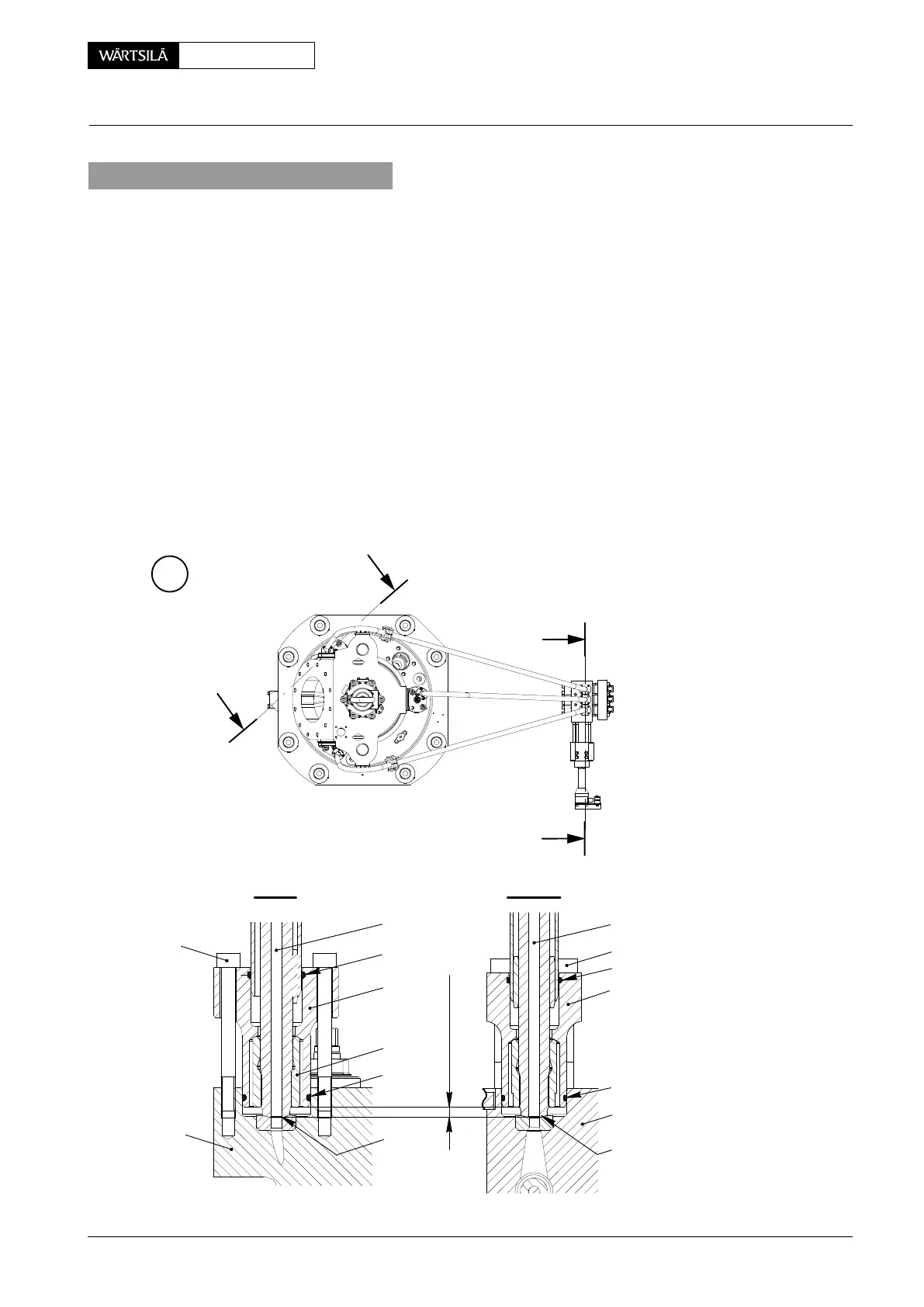

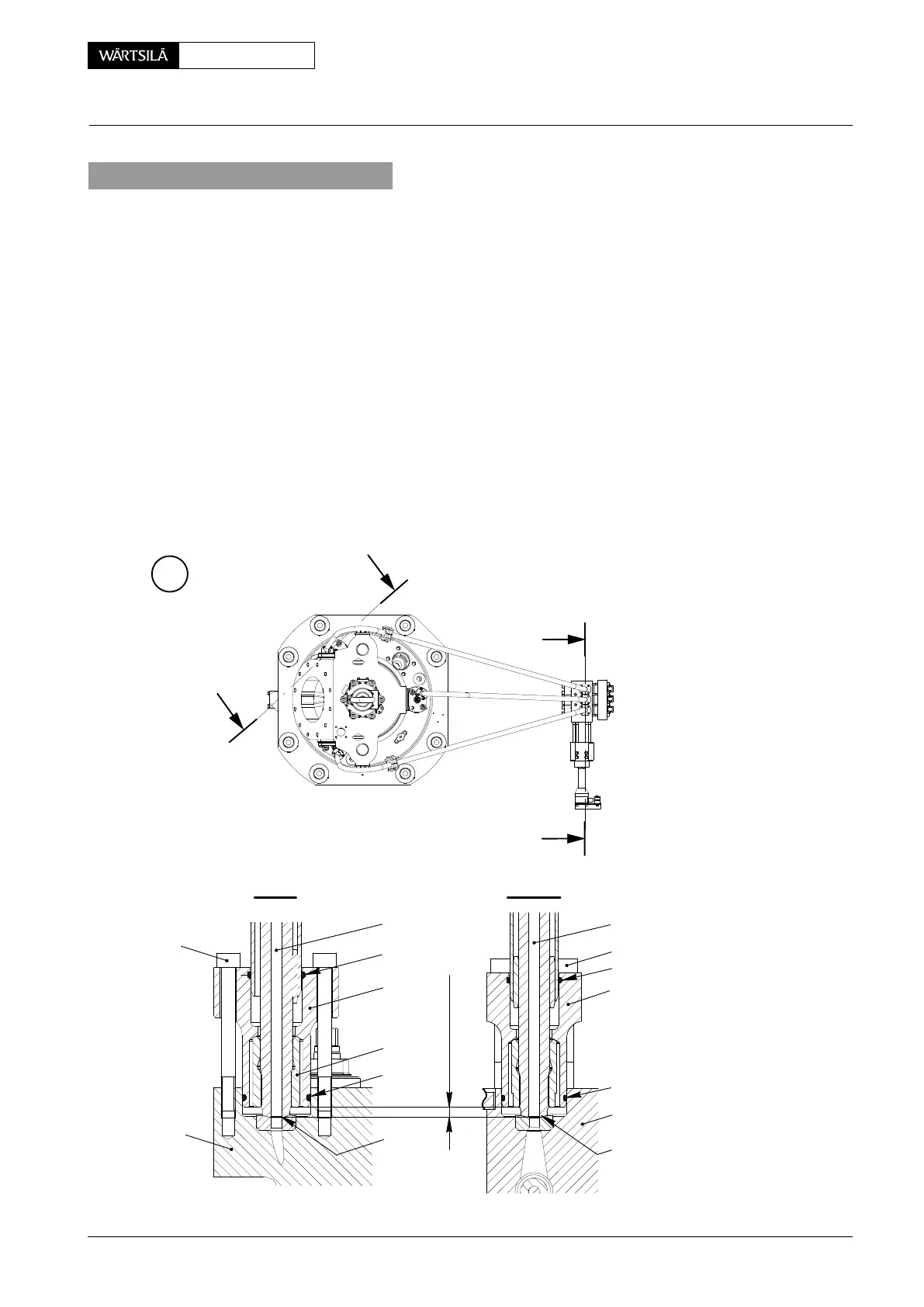

4. Installation

⇒ Use the special spanner 94874 to install the pipe claw 5.

⇒ Make sure that the claws 5 are correctly attached to HP injection pipe, i.e. that

the claw 5 are adjusted to the end of the thread on the pipe.

⇒ Make sure that there is a distance of X = 6 1 mm between the claw 5 and the

HP injection pipe 4.

⇒ If necessary, use an open-ended wrench to adjust the claw 5.

⇒ Remove all of the protection from the sealing faces ’SF’ in the injection valve 2

and the injection control unit 3.

⇒ Apply Never-Seez NSBT-8 to threads of screws 8 and 9.

⇒ Carefully put the HP injection pipe 4 in position in the injection valve 2 and the

injection control unit 3.

⇒ Torque symmetrically the four screws 8 to 25 Nm.

⇒ Torque symmetrically the four screws 9 to 25 Nm.

⇒ Install the applicable pipe bracket 10.

E

I

WCH02566

WCH02566

I

II

II

I - I

II -II

2

8

7

15

9

3

4

12

5

11

X = 6 1 mm

SF

SF

13

14

4

2014−07

HP Pipe to Injection Valve: Removal, Grinding and Installation

Loading...

Loading...