Maintenance

1132−2/A1

RT-flex58T-E

Winterthur Gas & Diesel Ltd.

3/ 14

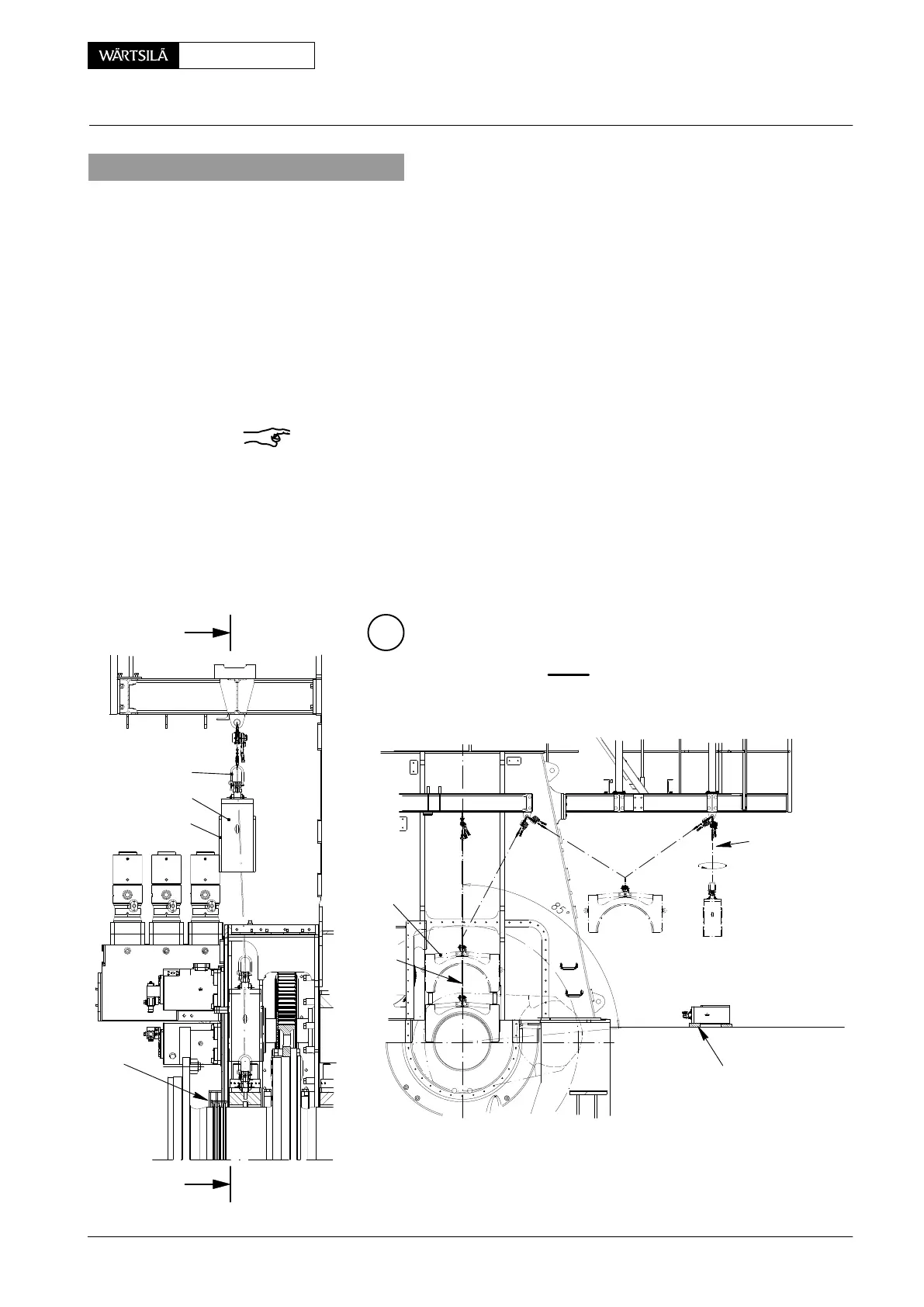

3. Removal of main bearing cover

3.1 Removal of bearing cover No. 1

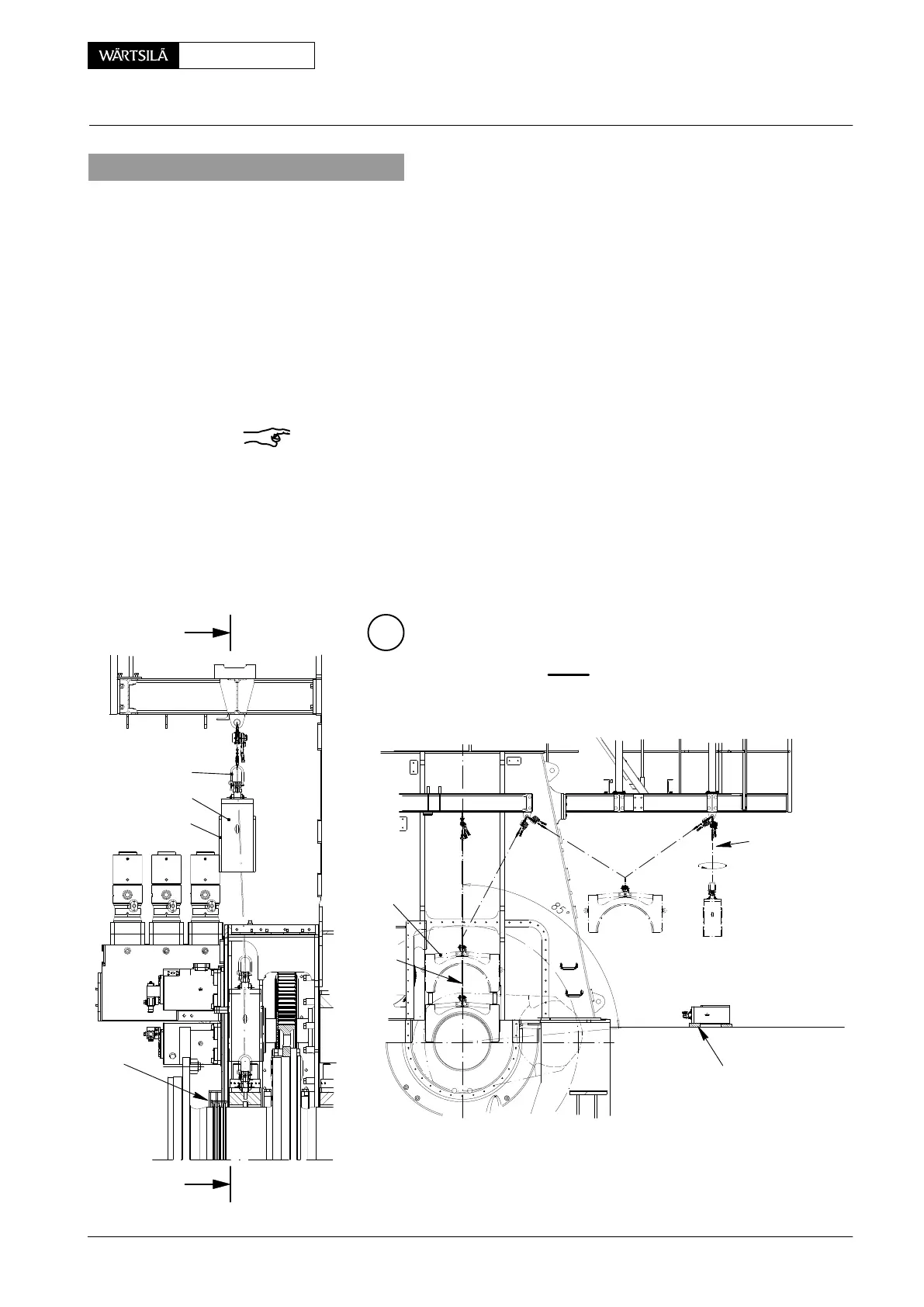

⇒ Turn crank of Cyl. No.1 to exhaust side approx. 85_ after T.D.C..

⇒ Remove upper part of oil baffle and upper casing at the driving end.

⇒ Protect slinger rings on the crankshaft.

⇒ Loosen nuts for elastic studs hydraulically (see 1132−1).

⇒ Place device 94111 with eyelet 94120 as described in section 2.

⇒ Lift bearing cover over the elastic bolts using rope 94120B and manual ratchet

’H1’.

Remark: Oil bore 7 in bearing girder 6 must be closed off immediately after lifting

the bearing cover, to prevent any dirt from entering (Fig. ’A’).

⇒ Remove the bearing cover from the column.

⇒ Connect ratchets ’H3’ with rope 94120B and ’H2’ and lift the bearing cover out

of the flywheel area.

⇒ Carefully put the bearing cover in horizontal position on wooden underlay

’WU’. Make sure the protruding bearing shell 10 does not get damaged.

C

I - I

I

I

H1

94120B

94111

2

PR

H2 H3

H2

WU

WCH01010

EXHAUST

SIDE

DRIVING END

94120B

94120

10

Removal and Fitting of a Main Bearing

V2 / 2013

Loading...

Loading...