Hydraulic System Checks

If the hydraulic system fails to operate

completely, or does so extremely slowly,

carry out the following procedures.

Check that the hydraulic tank is full of oil

to the correct level. The level is correct

when oil is 50mm from the top of the filler

neck.

Check that the filter has been regularly

cleaned in accordance with the

maintenance schedule. If not, clean filter.

Check that the hydraulic pressures are

correct as follows:

Tipping circuit

Fit a 2000 lb/in

2

gauge into the

hydraulic system at the base of a skip

ram.

Operate control lever to tip skip and

check the pressure reading on the

gauge when the rams are fully

extended and the relief valve is

‘blowing’. See “Specifications” for

correct pressure.

Steering circuit

Fit a 2000 lb/in

2

gauge into the

hydraulic system at the base of the

steering ram.

Turn the steering wheel until the

machine is at ‘Full Lock’ and check the

pressure reading on the gauge. See

“Specifications” for correct pressure.

If these procedures do not correct the

fault, contact your Distributor.

Periodically check the hose between the

pump and the hydraulic tank to ensure

that it is not deformed. Any deformation

in the hose may result in a restricted flow

and damage to the pump.

Every 10 operating hours, or

daily

Check hydraulic oil level

Do not check oil level before closing

the tipping rams, and the engine has

been stopped for 2 minutes.

Always clean the surrounding area before

removing the cap to prevent dirt from

entering the tank.

The oil level is correct when it is 50mm

(2”) from the top of the neck.

Do not overfill; it will cause leakage from

the breather!

First 100 operating hours

Clean / change tank strainer

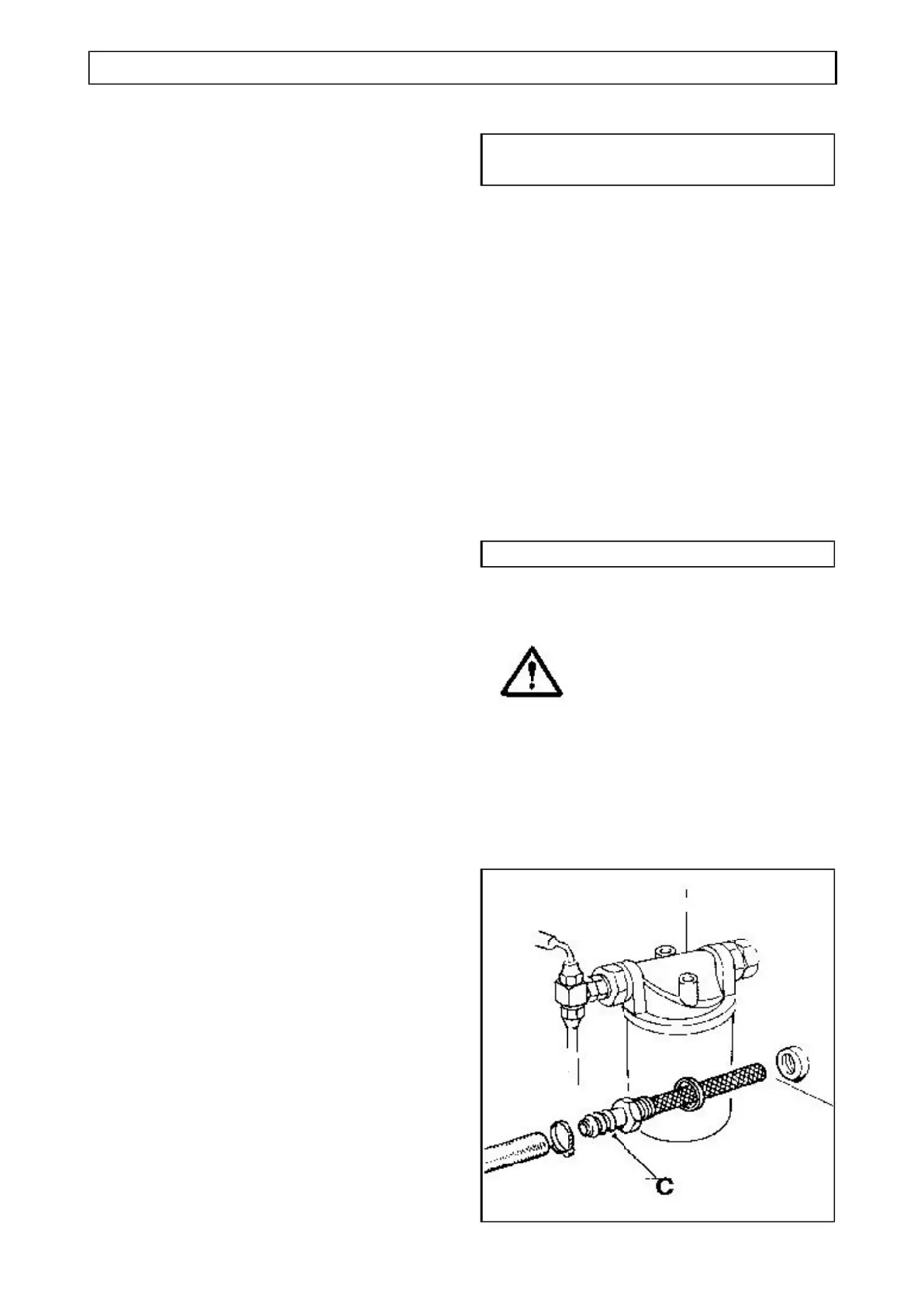

WARNING Before cleaning the tank

strainer, stop the engine and

dump hydraulic pressure.

Place a clean suitable container beneath

the hydraulic tank strainer. Clean the area

surrounding the strainer.

Disconnect the hose, then carefully

unscrew the strainer (C) from the tank

allowing the oil to drain into the container.

3.16 SERVICE

HYDRAULIC SYSTEM

Loading...

Loading...