V-Drive

+

/V-Drive economy Operating Manual

Page en-5

Release: 30.04.2019 2022 D005924 Index: 11

3.5.3 Additional Information

Environment

Prevent the penetration of the lubricant into drains, sewers, and water resources.

You can receive further information on the lubricants directly from the manufacturer:

Standard lubricant

OPTIGEAR SYNTHETIC 800/220

(formerly TRIBOL)

Lubricants for the food industry

(NSF-H1 registered)

Castrol Industrie GmbH, Mönchengladbach

Tel.: +49 2161 909-30

www.castrol.com

Klüber Lubrication München KG,

München

Tel.: 49 89 7876-0

www.klüber.com

Table 3.1

4 Technical Specifications

4.1 Design

The gearboxes are comprised of low-backlash angle gears.

All gearboxes are factory-filled with oil; gear input and output sides are sealed with radial

shaft sealings.

The clamping hubs enable a quick and easy mounting of the motor:

The motor is centred on the gearbox axle using the bearing-supported clamping hub

and not the adapter plate. The motor can thus be mounted without radial distortion.

High flexibility is assured by being able to adapt the reducer to various motors through the

functions of adapter plate and the spacer sleeve.

The gearbox has been designed to compensate for thermal linear expansion of the motor

shaft.

For varying applications, the gearbox is available with:

• Output flange “VDT

+

”,

• Output shaft “VDS

+

/VDSe” and

• Hollow output shaft “VDH

+

/VDHe”.

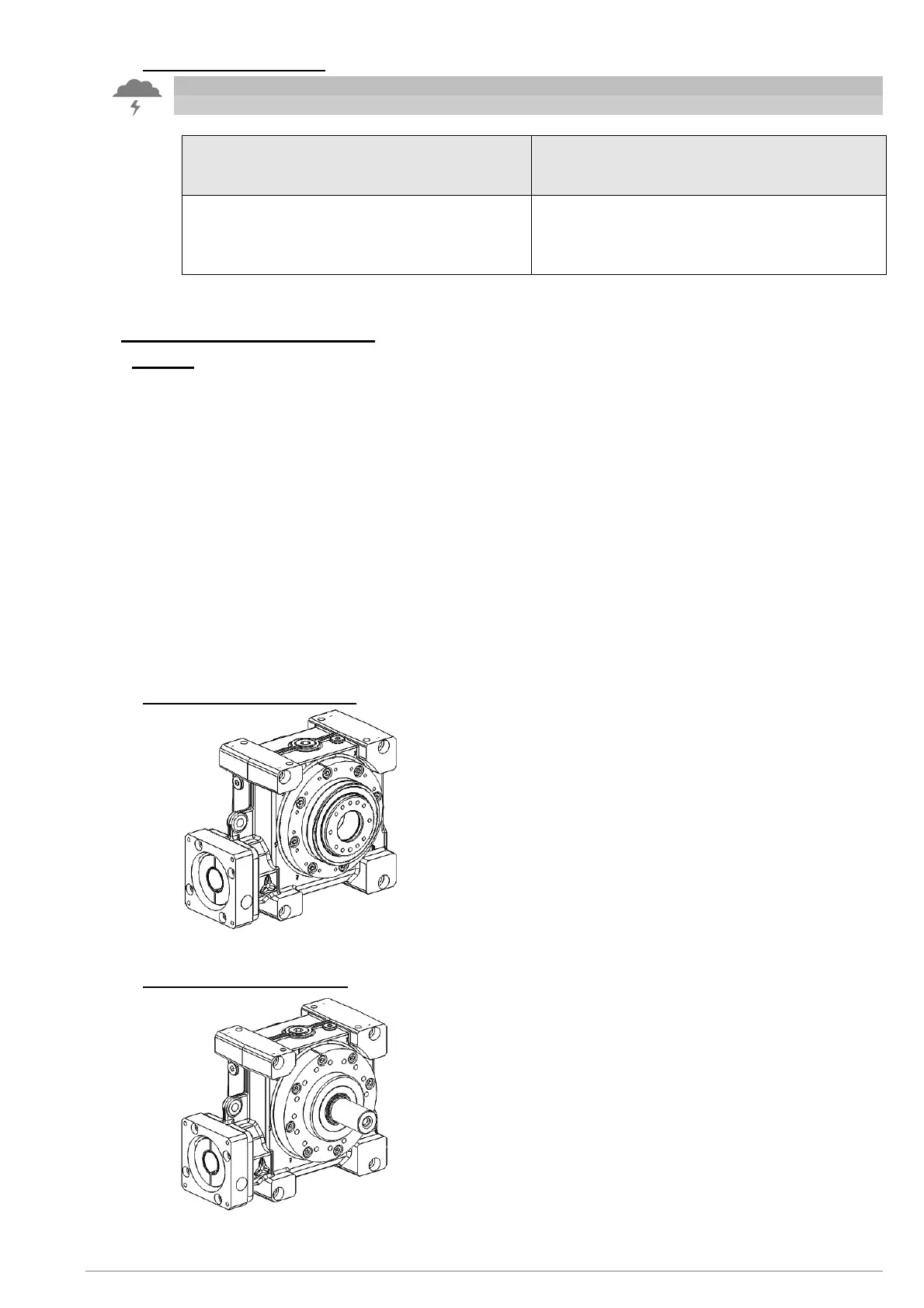

4.1.1 “VDT

+

” with output flange

Fig 4.1

The output flange, in accordance with ISO 9409, has two

centring mechanisms and a bore hole for an indexing pin so

that the gearbox (or the application) can be zeroed

mechanically.

The hollow shaft running through serves as a conduit for lines

or hoses, but does not aid in securing the load. On the back

side of the output flange, the position and/or the speed of the

load can be measured through the hollow shaft.

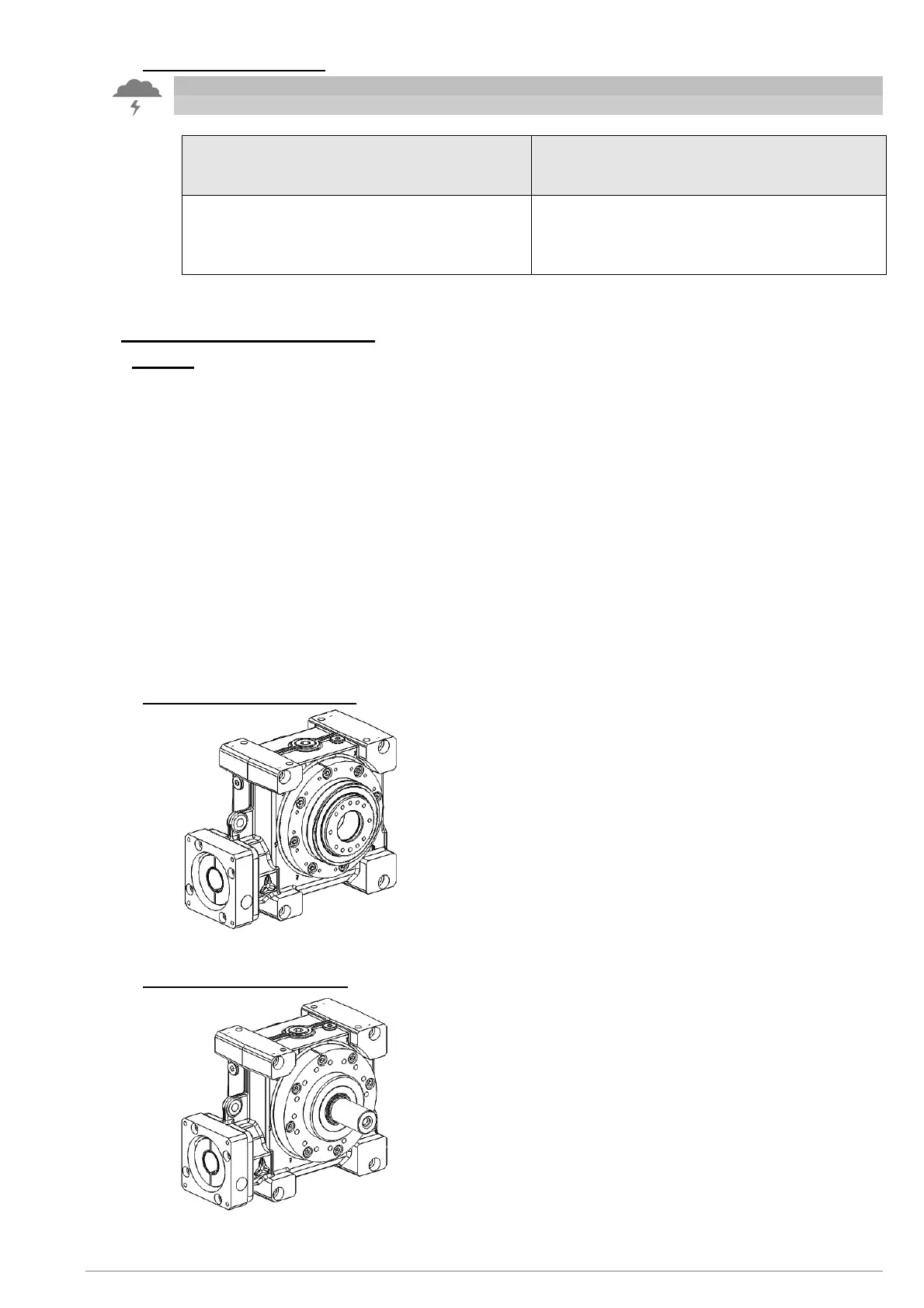

4.1.2 “VDS

+

” with output shaft

Fig 4.2

The output shaft is available in the following forms:

• Smooth face,

• With feather key groove (according to DIN 6885) or

• Involute (according to DIN 5480).

Loading...

Loading...