3064812_201804 23

16.Checkingthecombustionparameters

If work was carried out on the ionisation electrode or the ignition electrode during maintenance, carry out a full cali-

bration. See description HG43 in chapter "Parameter description" in the installation instructions.

The condensing boiler is equipped with electronic combustion control which ensures optimum combustion quality. For

a detailed description of the combustion control, see chapter "Combustion air control".

During commissioning and maintenance, a check of CO, CO

2

or O

2

is required. Testthecombustionparameters

withtheboilerclosed.

AuegasemissionstestbyacontractorisnecessaryaftereverymodicationoftheGBC-ePCB,

mixingdevice,burnerandgasvalve.

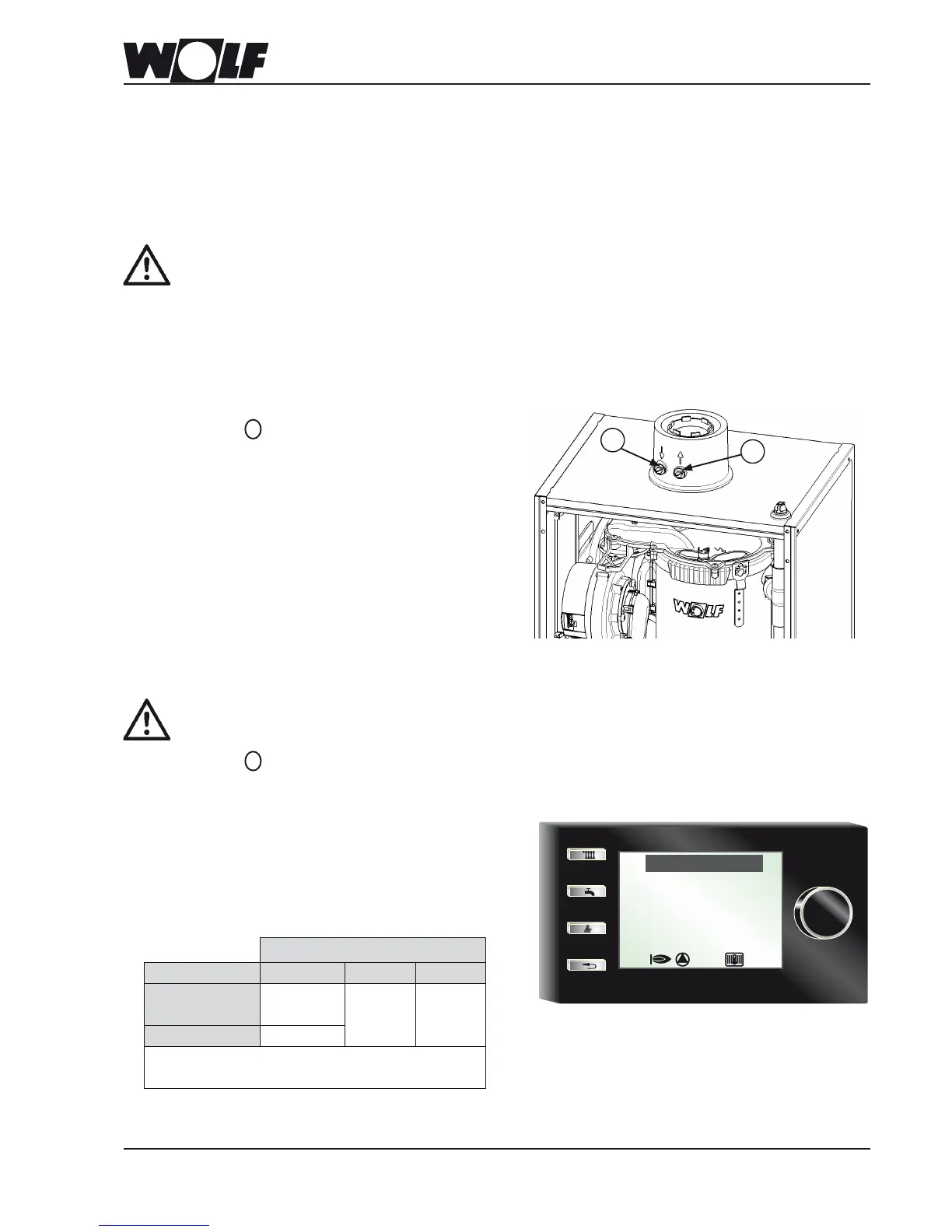

Checkingtheintakeair

1. Remove screw A from the left hand test port.

2. Open the gas ball valve.

3. Insert the test probe.

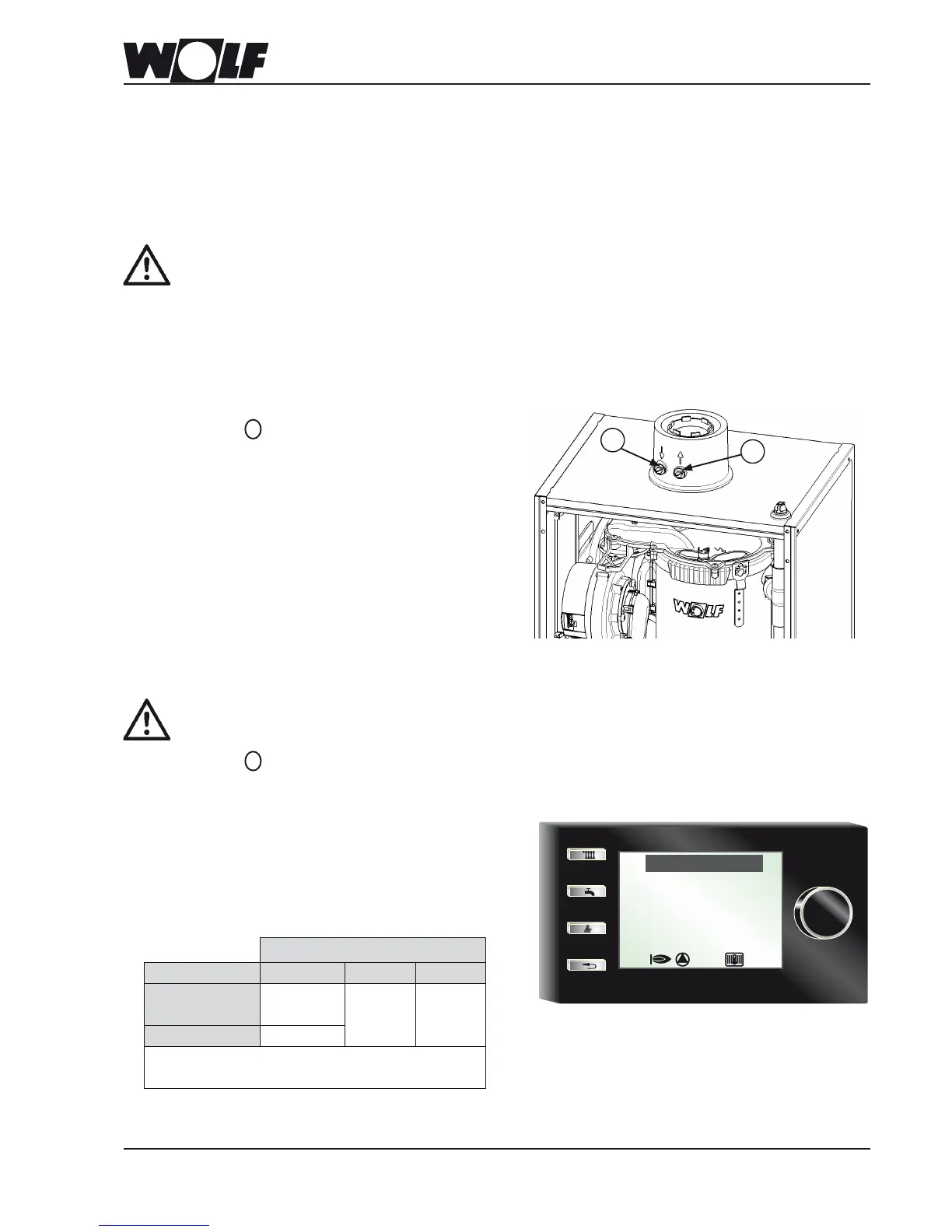

4. Switch ON the boiler and select Emissions test via

the function keys.

5. Check the temperature and CO

2

.

6. In the case of a balanced ue, the ue is not gas-

tight if the CO

2

content is > 0.3 %. The leak must be

rectied.

7. After the test has been completed, switch the boiler

OFF, remove the test probe and close the test port.

Ensure the screws are tightly secured.

Checkingtheuegasparameters

When the test port is open, ue gas can

escapeintotheinstallationroom.Thereis

ariskofasphyxiation.

1. Remove screw B from the right hand test port.

2. Open the gas ball valve.

3. Insert the test probe.

4. Switch ON the boiler and select the Emissions test

key.

5. Carry out the checks after a minimum of 60 seconds

of operation, measuring rst at maximum load and

then at minimum load.

6. Flue gas values (for permissible values, see table)

14/20/24kW-appliance

Gastype CO

2

in % O

2

in % Lambda

Natural gas E/H/

LL

7.8 - 9.8

1)

3.5 - 7.0 1.35

+/- 0.15

LPG (G31) 9.1 - 11.4

2)

1)

Max. base CO

2

value = 11.7 % (G20)

2)

Max. base CO

2

value = 13.7 % (G31)

7. After the test has been completed, switch the boiler

OFF, remove the test probe and close the test port.

Ensure the screws are tightly secured.

Note: The combustion control carries out an automatic calibration after every boiler start. This can lead to briey

increased CO emissions.

Therefore, test the emissions no sooner than 60 seconds after the burner has started.

Loading...

Loading...