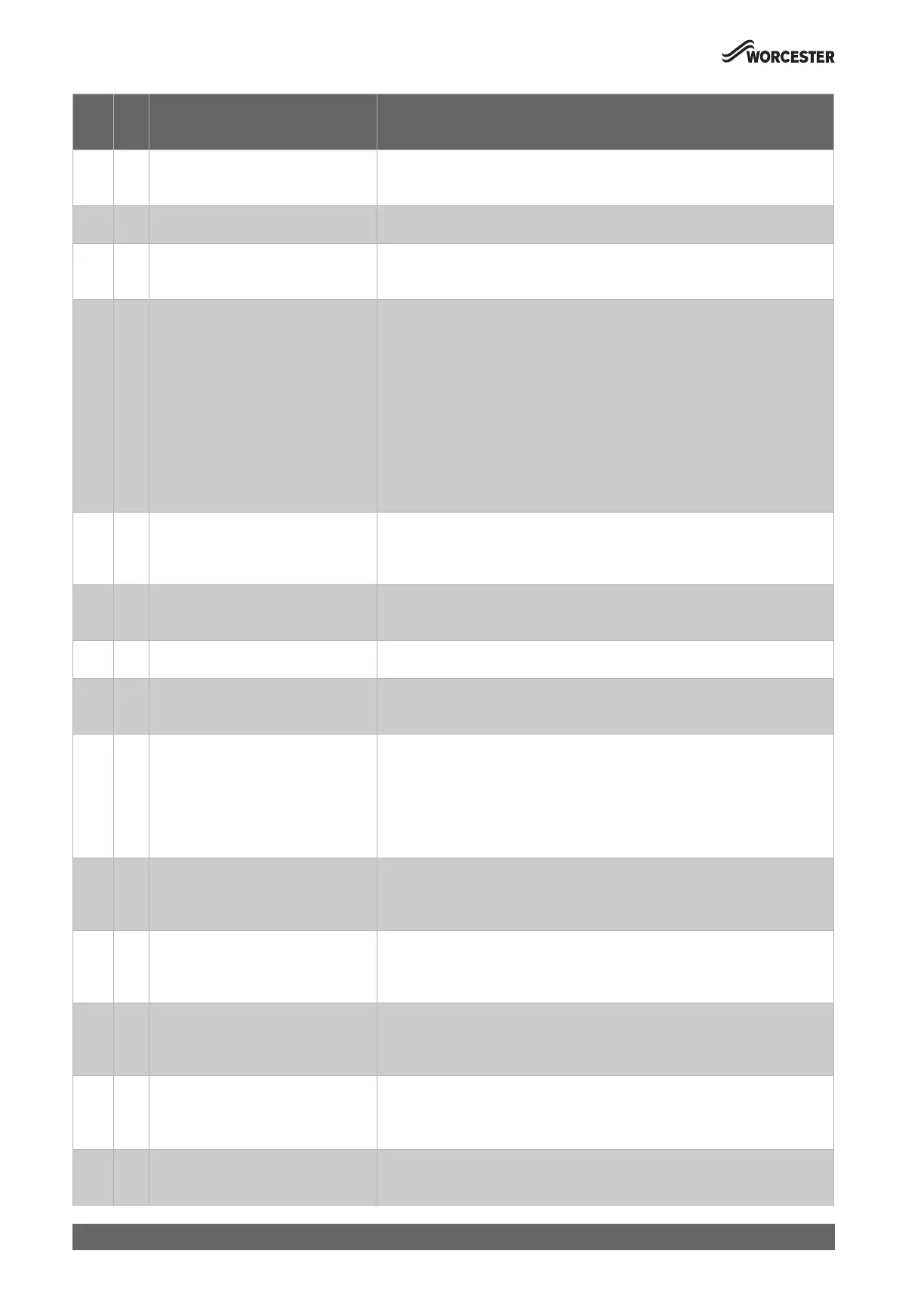

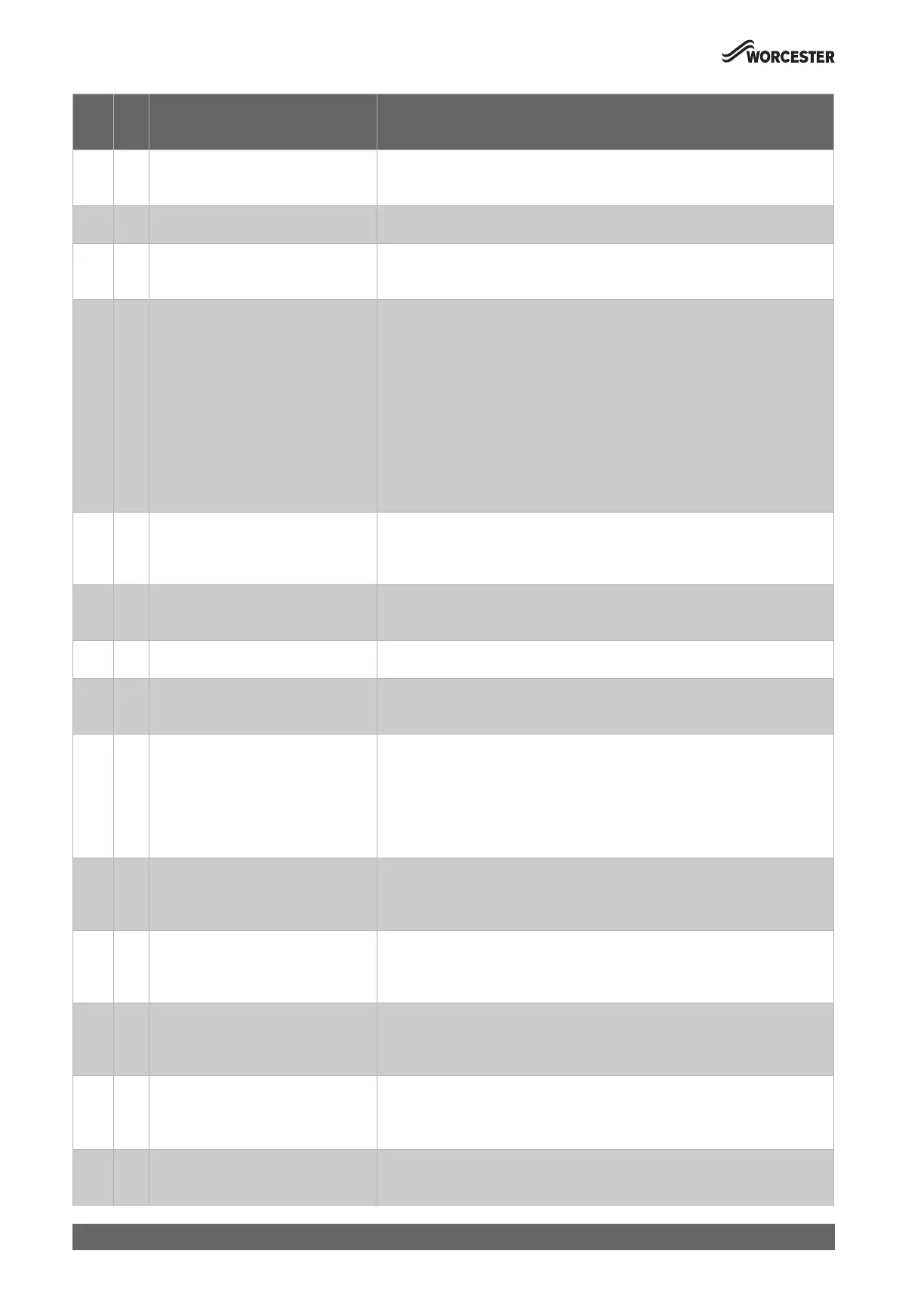

Fault finding and diagnosis

Greenstar 4000 – 6 720 891 161 (2020/09)

74

360 V System fault boiler electronics / basic

controller

▶ Wrong code plug is inserted.

▶ Check the code plug is not damaged.

▶ Replace the code plug if required.

362 – Boiler identification module or boiler

electronics faulty

Is not a fault.

• Service plug detected.

363 V System fault boiler electronics / basic

controller

▶ Check and replace the ionisation cable.

▶ Check and replace the electrodes if required.

▶ Check and replace the control unit and/or burner control unit.

1010 – No communication via EMS BUS

connection

▶ Check the grey ribbon on far right of the PCB (low voltage connection).

▶ If using a Key control product check the Key connections (black, white, red, green) are

plugged into the correct position on the PCB (under installer cover on the far right hand

side, leaving one space to the BUS connection).

▶ Check that the Key is pushed fully home.

▶ Check the batteries of the room control.

▶ Check the bridging links are fitted at LR & 230 V out.

▶ For wired room controls check the EMS BUS Voltage to the remote control is

12 - 15V DC.

▶ Check the 230 V external wiring does not run alongside the BUS connections, thus

causing interference.

▶ Replace the control unit

1013 W Max. combustion point reached (the

maximum burner time is reached)

The service reminder message is present due to the maximum burner hours service

threshold being reached.

▶ Carry out maintenance.

▶ Reset the maintenance code via the reset menu.

1017 W System pressure too low ▶ Top up system water and vent the system.

▶ Check the voltage to the pressure sensor and the signal back from the pressure sensor.

▶ Replace the pressure sensor.

1018 W Maintenance interval expired ▶ Carry out maintenance.

▶ Reset the maintenance code via the reset menu.

1019 W Incorrect pump type detected ▶ Pump communication failure or wrong pump is fitted (i.e. non-ErP).

▶ Check the pump communication wire is connected and has continuity.

▶ Replace the pump for correct modulating pump.

1021 B Cylinder charging or hot water temperature

sensor faulty

A 1021 error can only be cleared by powering the appliance off and back on again the hot

water sensor has been changed if open or short circuit, or refitted to the pipe if it has fallen

off.

▶ Check the domestic hot water temperature sensor is connected and the harness is

fitted securely to the sensor.

▶ Check the resistance of the temperature sensor and replace if required.

▶ Check the continuity of harness and replace if required.

1023 W Maximum run time including standby time

reached

The service reminder message is present due to the maximum run time (boiler hours)

being reached.

▶ Carry out maintenance.

▶ Reset the maintenance code via the reset menu.

1037 W Outside temp. sensor faulty - heating back-

up operation active

Tip: Check the weather compensation is applicable and the menu has not been

accidentally switched on in the menu.

▶ Check the positioning of the outside weather sensor.

▶ Check the weather sensor connections on the control board.

1065 W System pressure sensor faulty or not

connected

▶ Check the plug is connected correctly to the pressure sensor.

▶ Check pressure sensor connecting leads for breaks or short circuits, replace if

necessary.

▶ Check the pressure sensor, replace if necessary.

1068 W Outside temp. sensor or lambda probe

faulty.

▶ Check the plug to the temperature sensor, connect correctly.

▶ Check connecting lead for break or short circuit, replace if required.

▶ Check temperature sensor, replace if necessary.

▶ Check appliance electronics, replace control unit if necessary.

1070 W Maintenance is due on <dd.mm.yyyy>

please call your service engineer

Advanced service reminder warning.

▶ Check the maintenance menu.

▶ Reset the maintenance code via the reset menu.

Fault

code

Fault

category

Fault text on the display, description Remedy

Loading...

Loading...