Turb 2000 Series Installation and commissioning

ba75695e03 10/2013 11

2.2 Plumbing

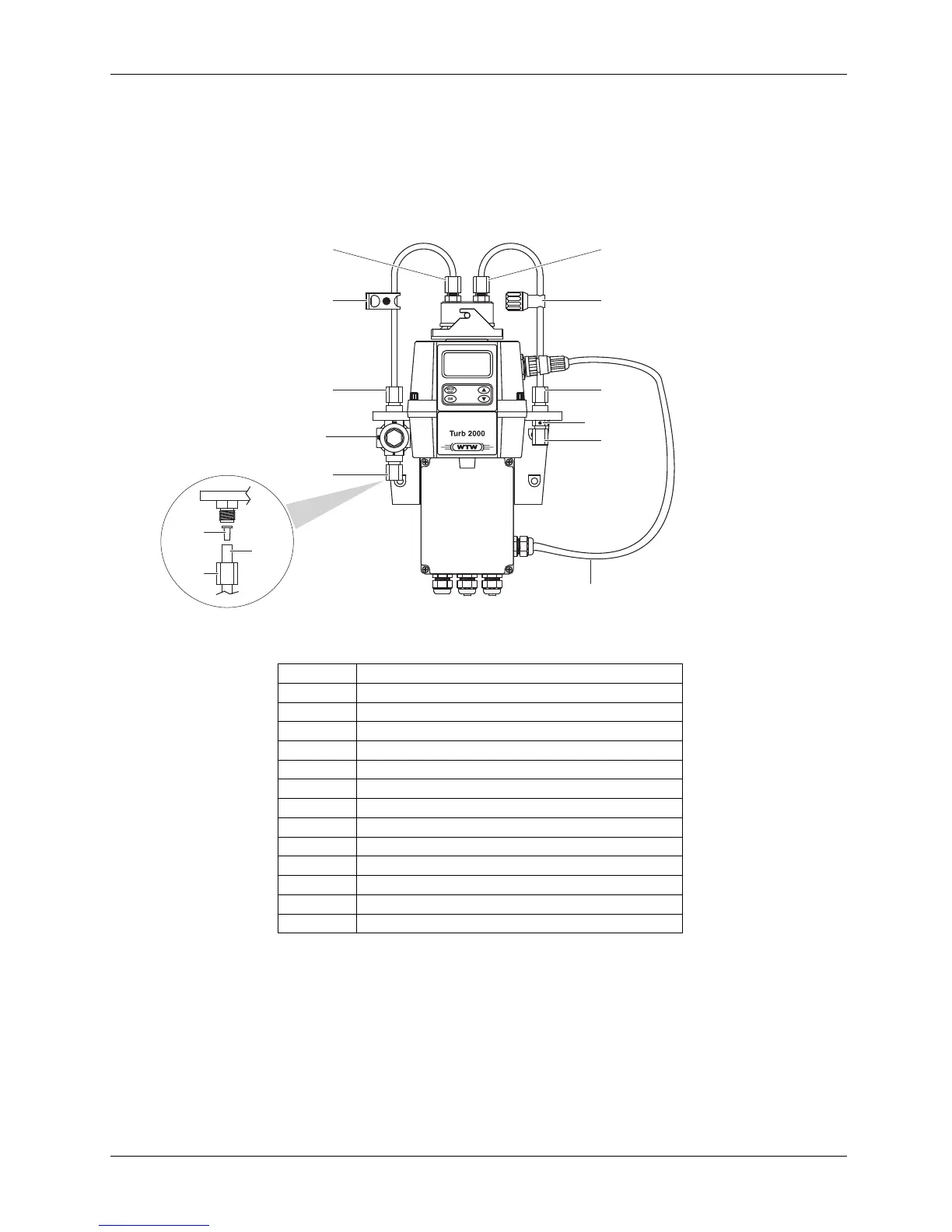

Figure 4 shows the plumbing recommended for the instrument. The instrument requires only a very low

minimum pressure for operation. A flow controller and backpressure valve are integrated in the

instrument. For details, see chapter Technical data.

IN

2

33

8

9

10

6

7

1

5

4

12

14

11

13

Figure 4: Recommended plumbing for the instrument

1 Feed tubing connection

2 Shutoff clamp

3 Feed tubing connection

4 Backpressure valve

5 Feed tubing connection

6 Drain tubing connection

7 Backpressure valve

8 Drain tubing connection

9 Drain vent

10 Drain tubing connection

11 Sensor connection cable

12 Insert

13 Tubing (not supplied)

14 Nut

The instrument is equipped to be plumbed using 4.75 mm (3/16”) ID, 8 mm (5/16”) OD flexible tubing.

Opaque tubing should be used if the tubing will be exposed to sunlight, to prevent algae growth. For

connectiong we recommend the conection set with quick connector (A-Set-DW, siehe section 11).

In figure 4, there are three flow devices shown. On the inlet side there is a shutoff clamp (Pos. 2) used

during cuvette maintenance, and the flow controller (Pos. 4). With the backpressure valve (Pos. 7) a

back pressure is created in the cell. Backpressure may be required to prevent air from coming out of

solution, which may be observed as tiny air bubbles.

Loading...

Loading...