install. For shaft without keyway, friction coupling or similar methods are used.

◆ When the pulley is dismantled, the pulley mover is used to prevent the bearing from

being strongly impacted by the load.

◆ To ensure safety, protective covers or similar devices, such as pulleys installed on shaft,

are installed in the rotating area.

Item Description

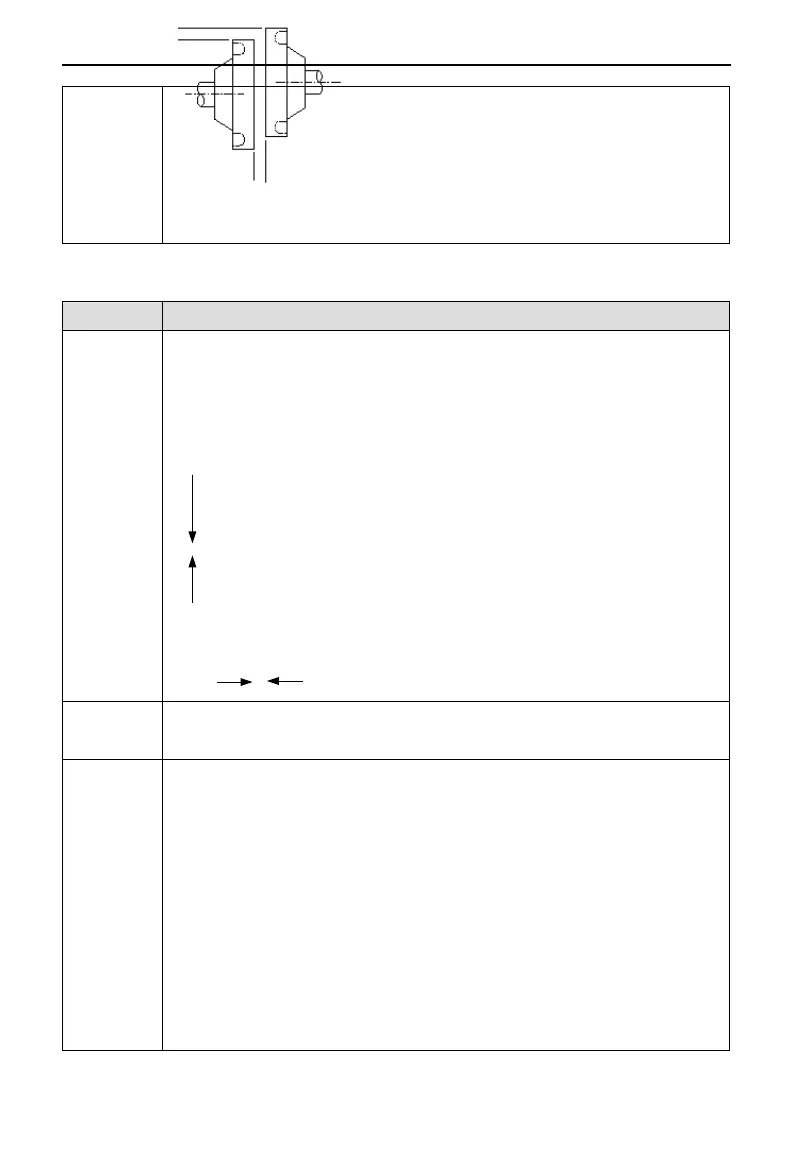

Centering

◆ When installing the servo motor, make it conform to the centering accuracy requirement

shown in the picture below. If the centering is inadequate, vibration will occur, and

sometimes the bearing and encoder may be damaged. When installing the coupling, please

do not directly impact the motor shaft, otherwise the encoder installed on the opposite side

of the load shaft will be damaged.

Installation

direction

◆ Servo motor can be installed in horizontal or vertical direction.

Oil and

water

solutions

When using in places where water droplets are dropping, please use it on the basis of

confirming the protection level of servo motor. (except for the shaft-through part) When

oil droplets will drip into the shaft-through part, please specify the servo motor with oil

seal.

Conditions for use of servo motors with oil seals:

◆Make sure the oil level is below the lip of the oil seal when using.

◆Please use the oil seal to keep the splash of oil droplets in good condition.

◆When the servo motor is installed vertically upward, please pay attention not to oil

accumulation on the lip of the oil seal.

18

coupling) measured at four locations in a circle.

(rotated with the coupling) measured at four locations in a circle.

Loading...

Loading...