XYZ Machine Tools

ProTURN SLX 1630 ProtoTRAK SLX CNC Safety, Installation, Service & Parts List Manual

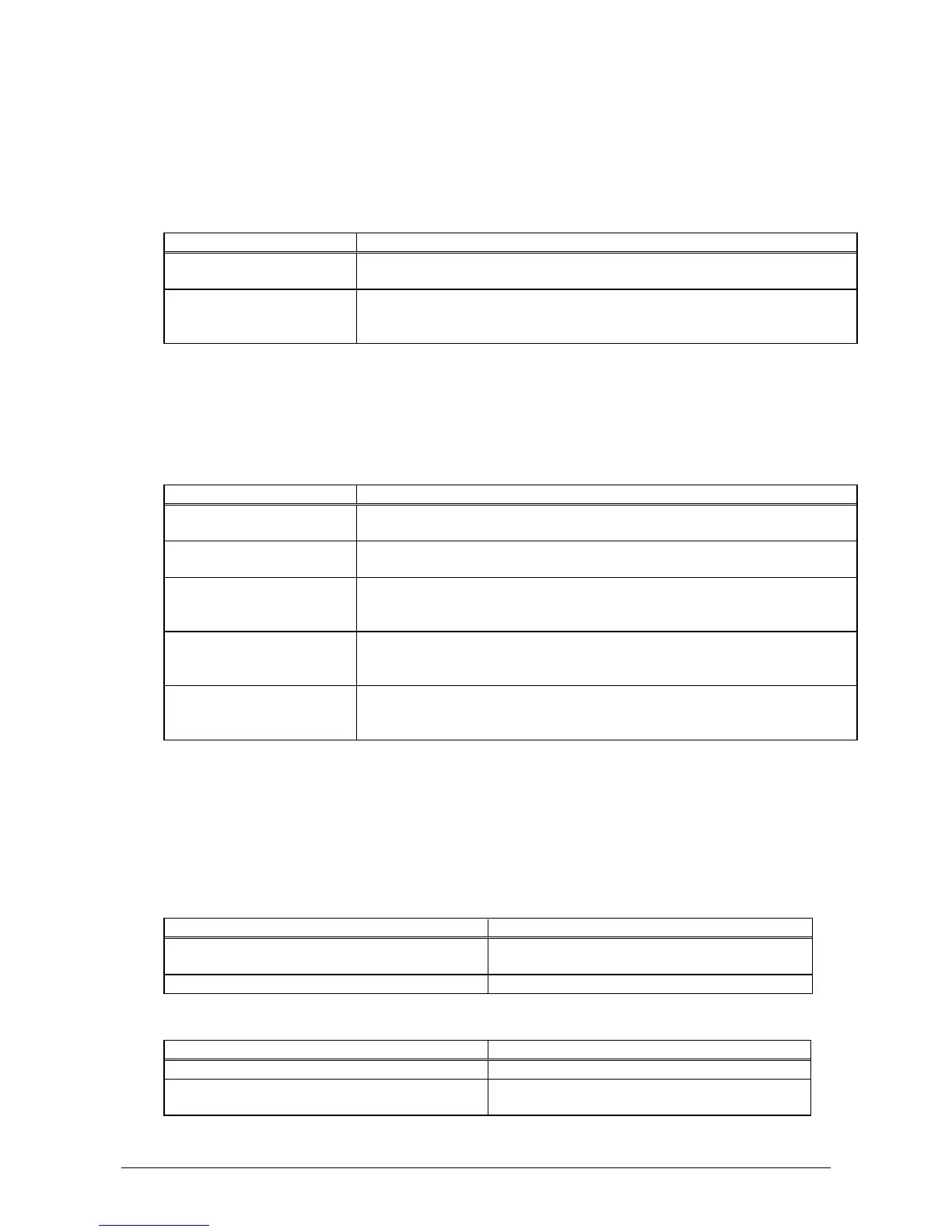

3.1.2 Turning Diameters Out of Round

Parts are not round within .015 mm TIR for SLX 1630. This is best measured by

using a .002 mm dial indicator and mounting to the inside taper of the spindle.

Rotate the spindle and measure the indicator movement.

Do the following service code and procedures:

Improper tooling, workpiece not properly supported.

See Machine Tool & Setup, Section 4.1.

Looseness in the spindle bearings. See Mechanical Drive Train (X, Z),

Section 4.2. Spindle bearing not preloaded correctly. Reseat bearing and

preload. See Spindle Bearing Preload, Section 5.1.16.

3.1.3 Cutting Taper

Parts are considered to be cutting on a taper if there is a difference in diameter of more than

.02 mm over 152.4 mm. This is best measured by using a .002 mm micrometer.

Do the following service code and procedures:

Code 12 Determines the feed forward constant for the axis motors.

Machine not leveled properly

See Leveling - Section 2.9.

Improper tooling; Work piece not properly supported. Use steady rest or

follow rest, reduce overhang from chuck headstock or tailstock.

Looseness in the gib or

misalignment of ball screw

Gib adjustment.

See Gib Adjustment - Section 5.2.1.

See Z Ball screw Alignment - Section 5.1.14.

Looseness in the spindle bearings.

See Mechanical Drive Train (X,Z) - 4.2.

See Spindle Bearing Preload - Section 5.1.16.

Headstock and/or tailstock

not aligned

See Adjust Headstock for Taper - Section 5.1.15.

To adjust tailstock from side to side, adjust gib screw. See Aligning

Tailstock to Spindle Section 5.1.17.

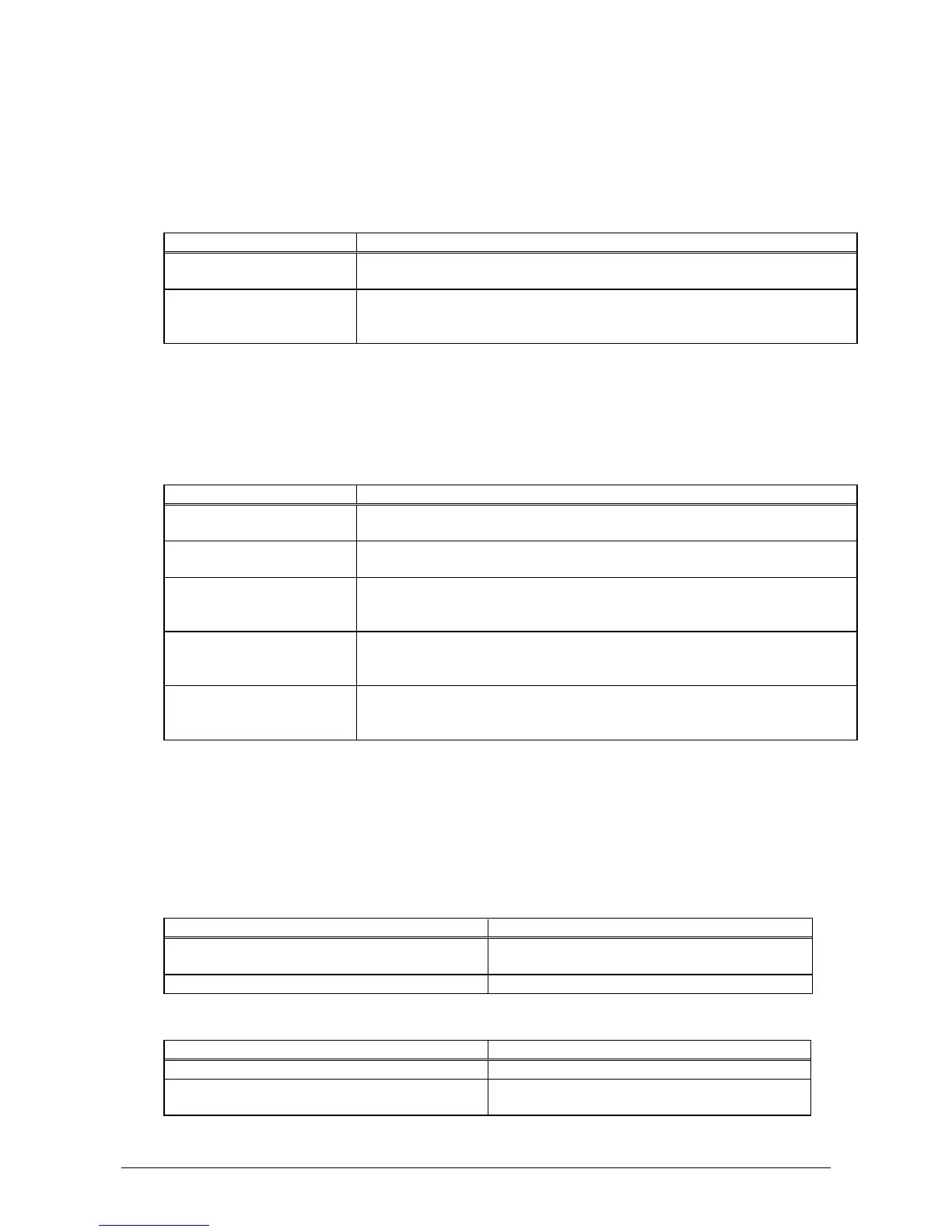

3.1.4 Parts Have Incorrect Dimensions

Parts are being machined with dimensions that are different than those programmed.

Typical accuracy expectations should be:

Parts should be round within .015 mm TIR on both the SLX 1630.

The acceptable measurement of parallelism of spindle axis to carriage movement

is .02 mm over 152.4 mm.

3.1.4.1 Every Part Has the Same Error

Programmed dimensions not correct. Check

absolute and incremental values.

See Machine Tool & Setup - 4.1.

3.1.4.2 Errors are Random or Accumulate in Size over the Part Run

See Machine Tool & Setup - 4.1.

Looseness in the Drive Train, ball nut loose in

yoke, split nut loose, yoke loose

See Mechanical Drive Train (X,Z) - 4.2.

Loading...

Loading...