Chapter 6 Cooling Water System

5. Pressure Cap and Sub Tank

,

4LHA Series

5.

Pressure

Cap and Sub

Tank

5-1

Pressure

cap

construction

The pressure cap mounted on the fresh water filler neck

incorporates a pressure control valve. The cap is mounted

on the filler neck cam by placing it on the rocking tab and

rotating. The top seal of the cap seals the top of the filler

neck, and the pressure valve seals the lock seat.

5-2

Pressure

cap

pressure

controi

The pressure valve and vacuum seal

both

seal the valve

seat when the pressure in the fresh water system is

within

the specified value of 0.088(0.9)MPa(kgf/cm). This seals

the fresh water system.

When the pressure

within

the fresh water system exceeds

the specified value, the pressure valve opens, and steam

is

discharged through the overflow pipe. When the fresh

water is cooled and the pressure

within

the fresh water

system drops below the normal value, atmospheric

pressure opens the vacuum valve, and air is drawn in

through the overflow pipe.

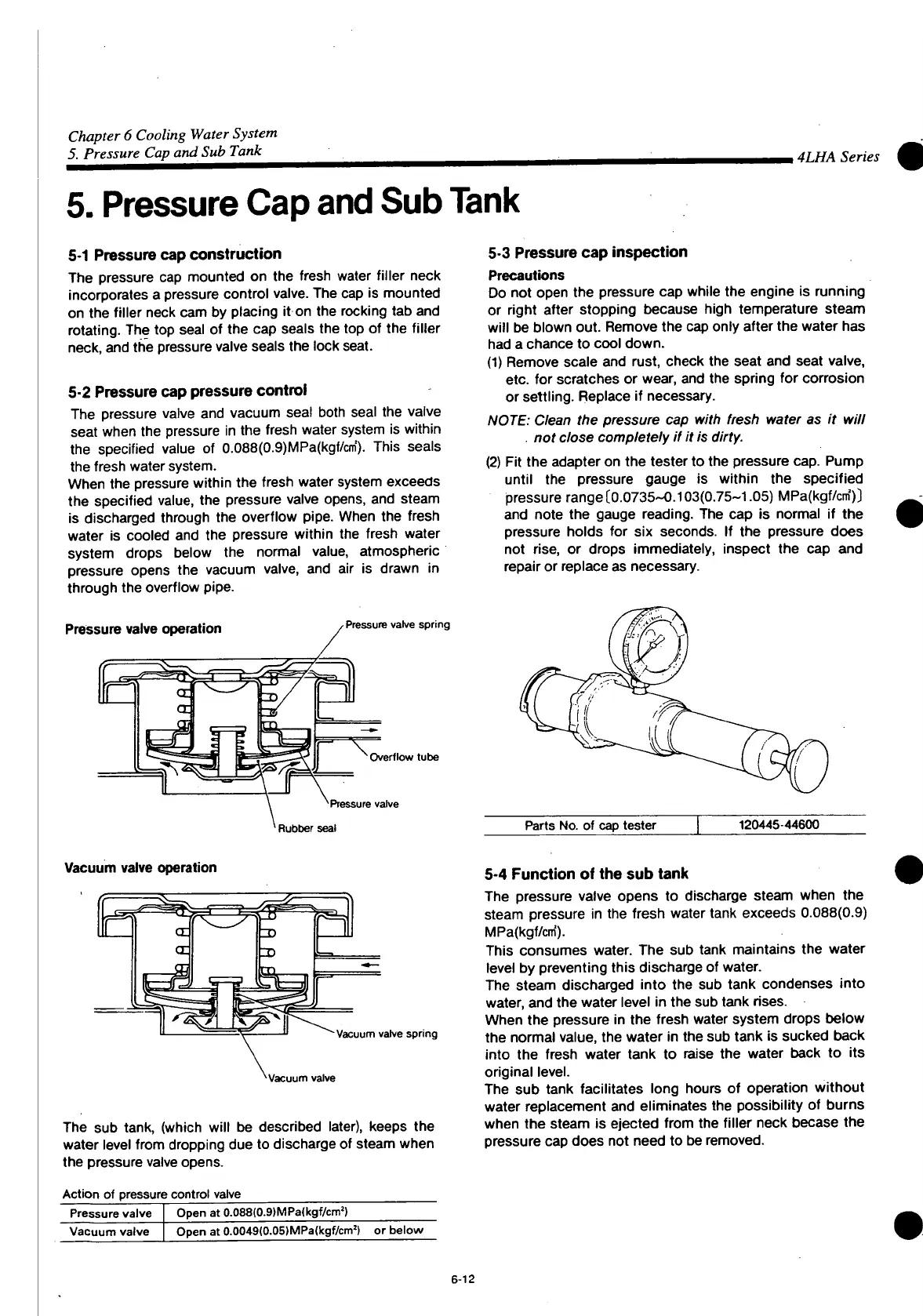

Pressure

valve

operation

Pressure

valve spring

Overflow tube

Pressure

valve

Rubber

seal

5-3

Pressure

cap

inspection

Precautions

Do

not open the pressure cap while the engine is running

or

right

after stopping because high temperature steam

will

be blown out. Remove the cap only after the water has

had a chance to cool down.

(1) Remove scale and rust, check the seat and seat valve,

etc. for scratches or wear, and the spring for corrosion

or settling. Replace if necessary.

NOTE: Clean the pressure cap with fresh water as it will

not close completely if it is dirty.

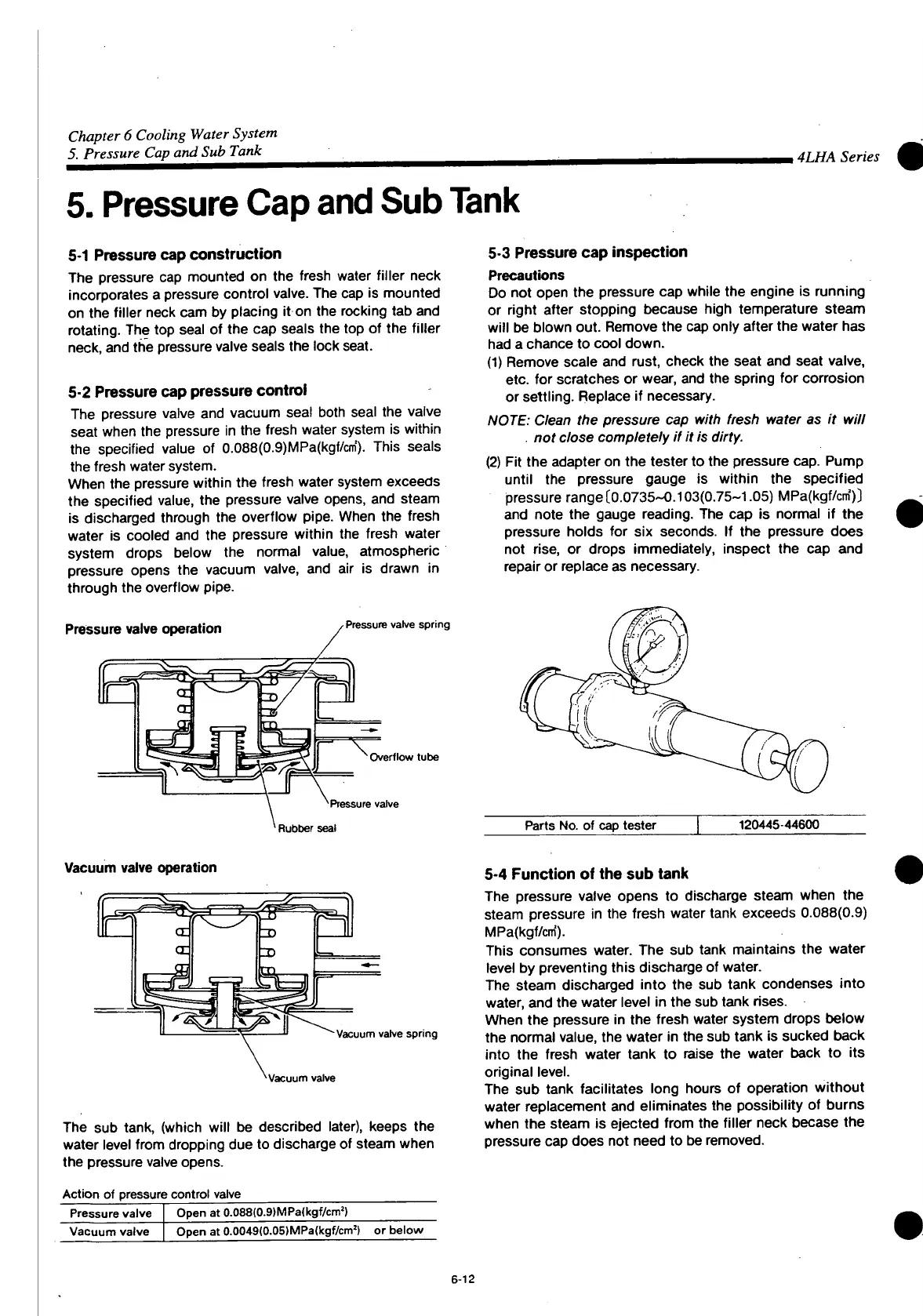

(2) Fit the adapter on the tester to the pressure cap. Pump

until

the pressure gauge is

within

the specified

pressure range [0.0735-0.103(0.75-1.05) MPa(kgf/cm)]

and note the gauge reading. The cap is normal if the

pressure holds for six seconds. If the pressure does

not rise, or drops immediately, inspect the cap and

repair or replace as necessary.

Parts

No. of cap tester

120445-44600

Vacuum

valve

operation

Vacuum

valve spring

Vacuum

valve

The sub tank, (which

will

be described later), keeps the

water level

from

dropping due to discharge of steam when

the pressure valve opens.

Action of pressure control valve

Pressure

valve

Open

at 0.088(0.9)MPa(kgf/cm

!

)

Vacuum

valve

Open

at 0.0049(0.05)MPa(kgf/cm

J

) or below

5-4

Function

of the sub

tank

The pressure valve opens to discharge steam when the

steam pressure in the fresh water

tank

exceeds 0.088(0.9)

MPa(kgf/cm).

This consumes water. The sub

tank

maintains the water

level by preventing this discharge of water.

The steam discharged

into

the sub

tank

condenses

into

water, and the water level in the sub

tank

rises.

When the pressure in the fresh water system drops below

the normal value, the water in the sub

tank

is sucked back

into

the fresh water

tank

to raise the water back to its

original level.

The sub

tank

facilitates long hours of operation

without

water replacement and eliminates the possibility of burns

when the steam is ejected

from

the filler neck becase the

pressure cap does not need to be removed.

6-12

Loading...

Loading...