Chapter 3 Fuel Injection Equipment

9. Pump Reassembly, Adjustment and Inspection

i

4LHA Series

9. Pump Reassembly,

Adjustment

and

Inspection

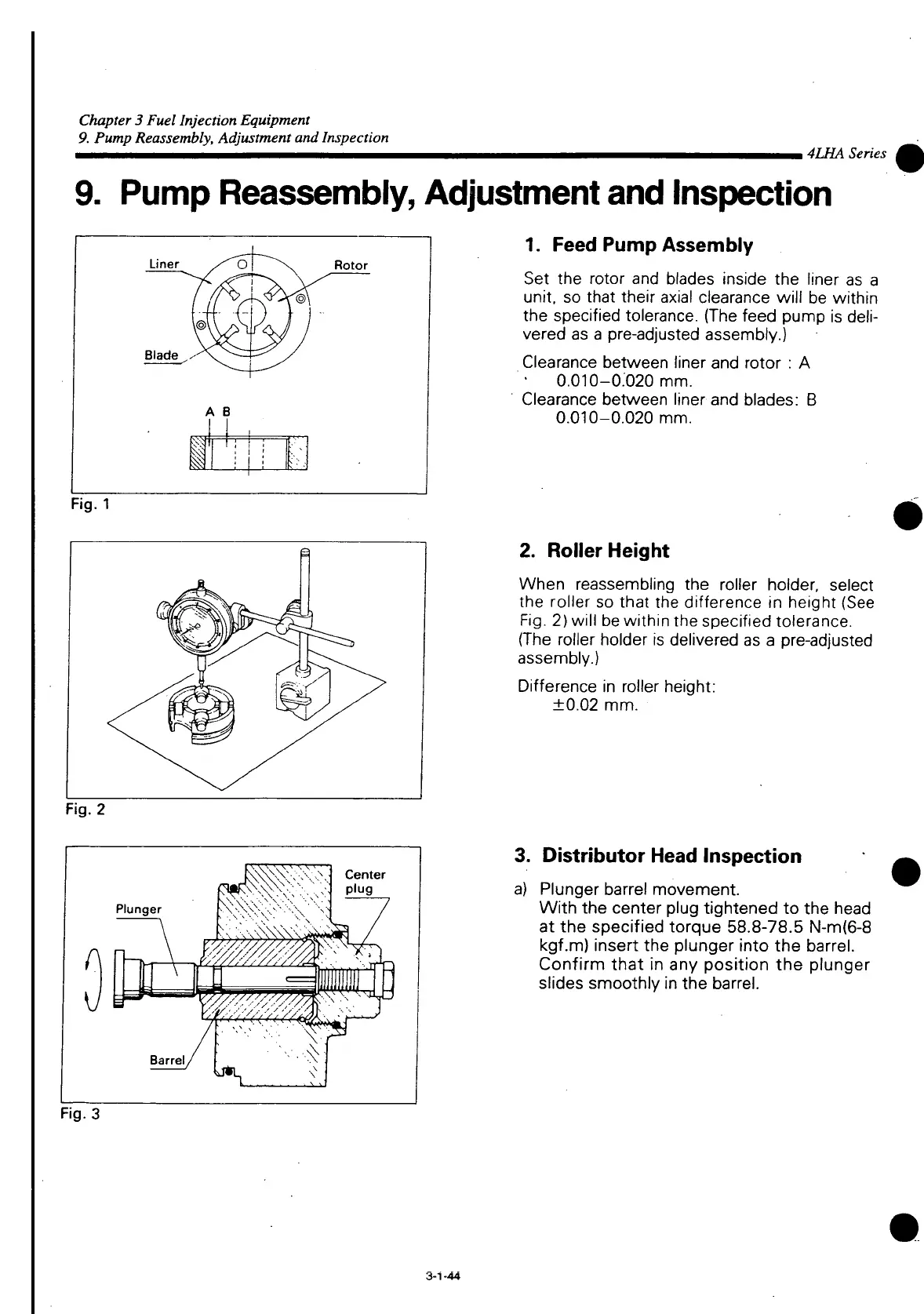

1. Feed Pump Assembly

Set

the rotor and blades inside the liner as a

unit, so

that

their axial clearance will be within

the specified tolerance. (The feed pump is deli-

vered as a pre-adjusted assembly.)

Clearance

between liner and rotor : A

0.010-0.020 mm.

Clearance

between liner and blades: B

0.010-0.020 mm.

Fig.

1

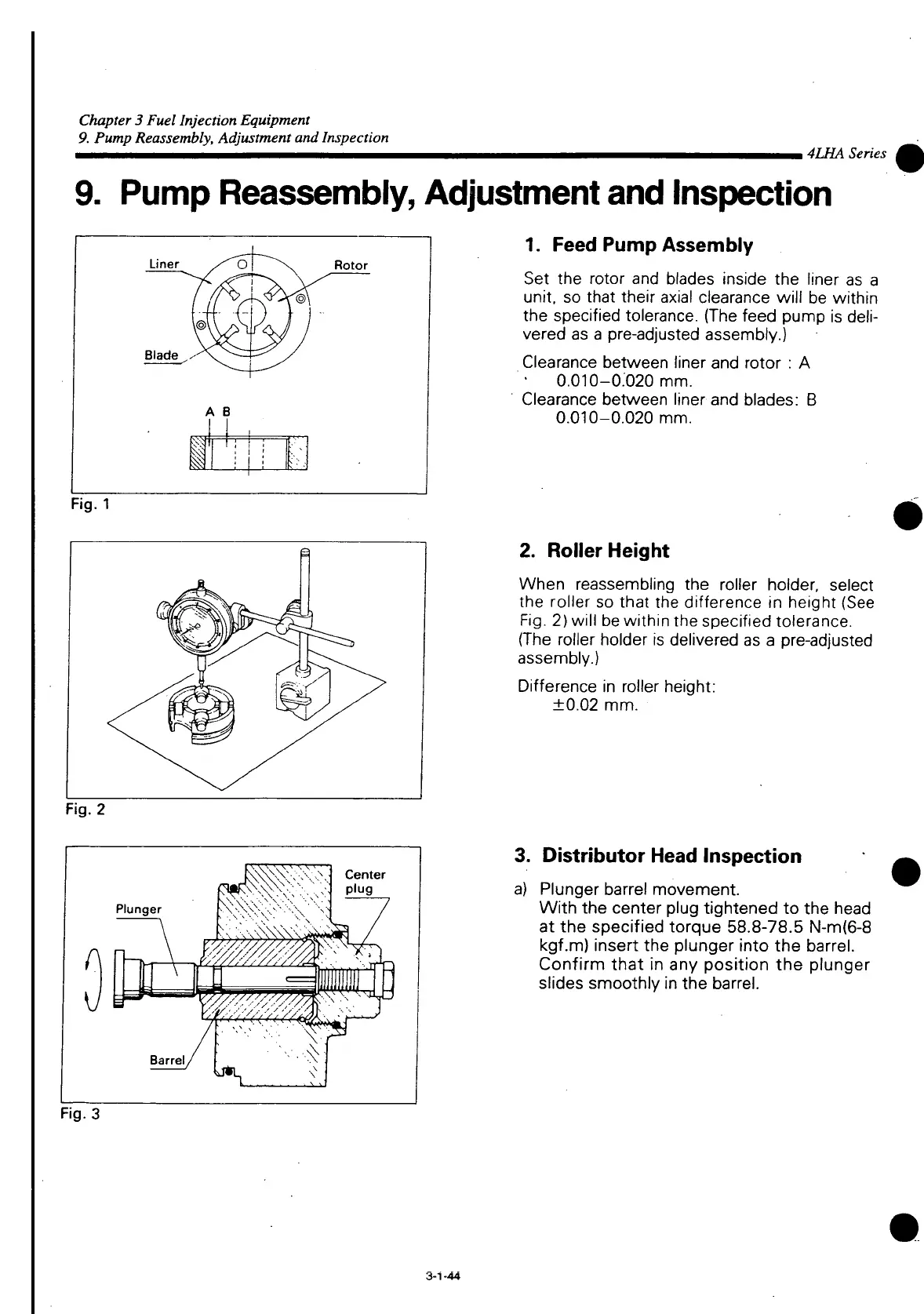

2. Roller

Height

When

reassembling the roller holder, select

the roller so

that

the difference in height (See

Fig.

2) will be within the specified tolerance.

(The roller holder is delivered as a pre-adjusted

assembly.)

Difference in roller height:

±0.02 mm.

Fig.

2

\V\\\\vv-N

\\

•

Center

plug

3.

Distributor

Head

Inspection

a) Plunger barrel movement.

With the center plug tightened to the head

at the specified torque 58.8-78.5 N-m(6-8

kgf.m) insert the plunger into the barrel.

Confirm

that

in any position the plunger

slides

smoothly in the barrel.

Fig.

3

3-1-44

Loading...

Loading...