Chapter

3

Fuel Injection Equipment

9. Pump Reassembly, Adjustment and Inspection

Part

No. 157829-3520

Part

No. 157829-8620

(Shaft)

Fig.

16

i

4LHA Series

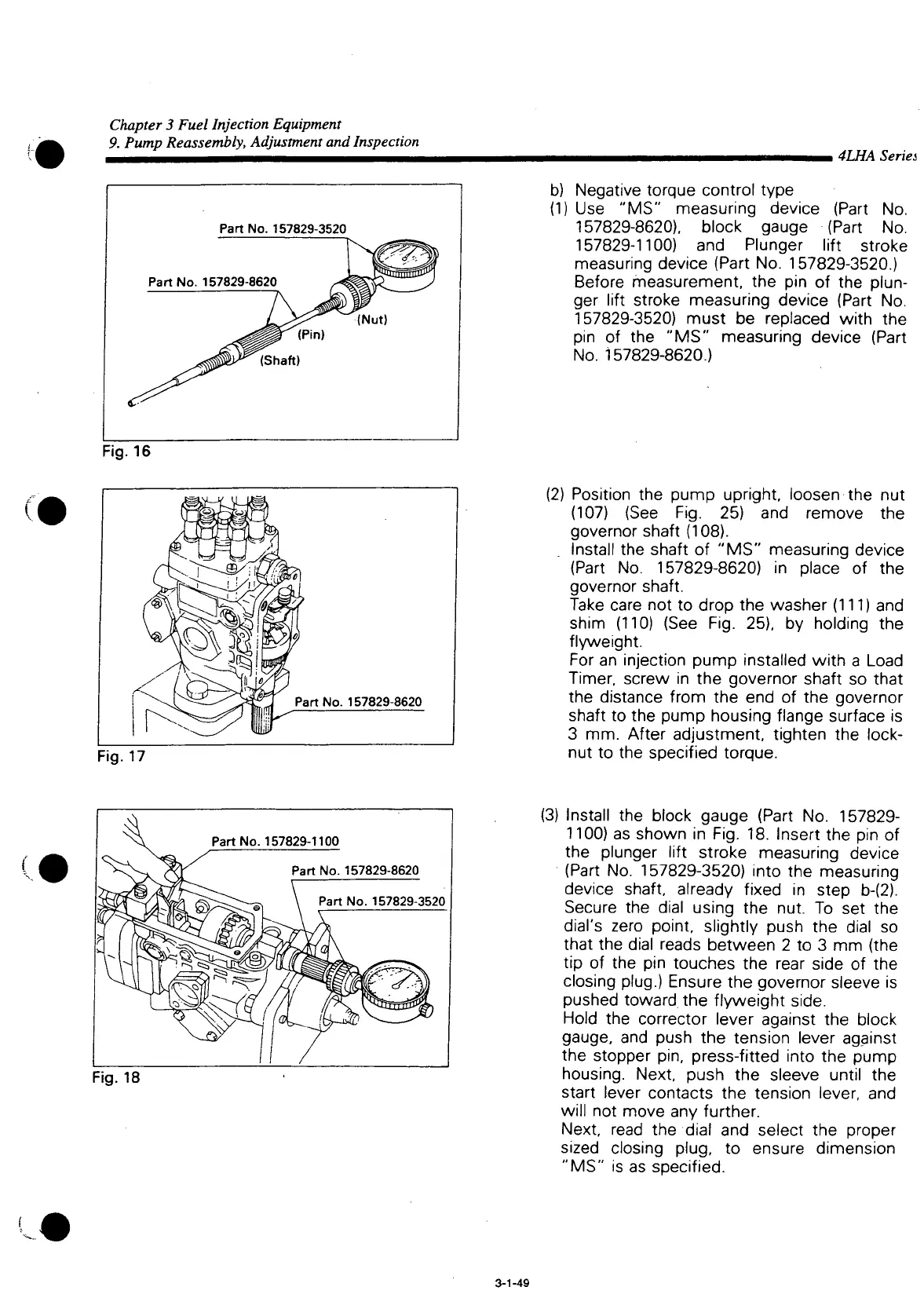

b) Negative torque control type

(1)

Use "MS"

measuring device (Part

No.

157829-8620). block gauge (Part

No.

157829-1100)

and

Plunger

lift

stroke

measuring device (Part No. 157829-3520.)

Before measurement,

the pin of the

plun-

ger

lift

stroke measuring device (Part

No.

157829-3520) must

be

replaced

with

the

pin

of the "MS"

measuring device (Part

No.

157829-8620.)

Fig.

17

(2) Position

the

pump

upright,

loosen

the nut

(107)

(See Fig. 25) and

remove

the

governor shaft (108).

Install

the

shaft

of

"MS" measuring device

(Part

No.

157829-8620)

in

place

of the

governor shaft.

Take

care

not to

drop

the

washer

(111) and

shim

(110) (See Fig. 25), by

holding

the

flyweight.

For

an

injection pump installed

with

a

Load

Timer, screw

in the

governor shaft

so

that

the distance

from

the end of the

governor

shaft

to the

pump housing flange surface

is

3

mm.

After adjustment,

tighten

the

lock-

nut

to the

specified torque.

Part

No.

157829-1100

Part

No.

157829-8620

Part

No.

157829-3520

Fig.

18

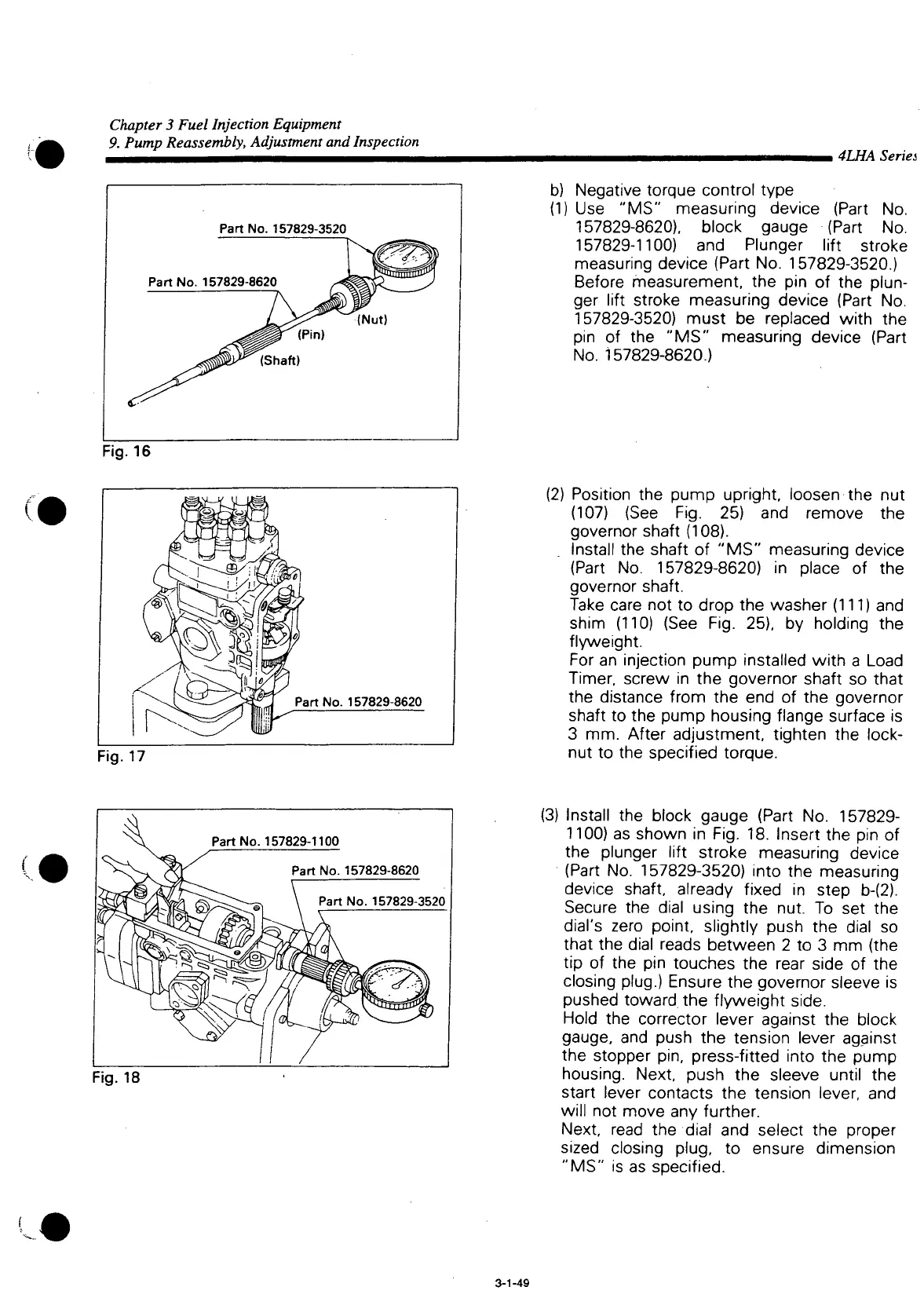

(3)

Install

the

block gauge (Part

No.

157829-

1100)

as

shown

in

Fig.

18.

Insert

the pin of

the plunger

lift

stroke measuring device

(Part

No.

157829-3520)

into

the

measuring

device

shaft, already fixed

in

step

b-(2).

Secure

the

dial using

the nut. To set the

dial's

zero point, slightly push

the

dial

so

that

the

dial reads between

2 to 3 mm (the

tip

of the pin

touches

the

rear side

of the

closing

plug.) Ensure

the

governor sleeve

is

pushed toward,

the

flyweight

side.

Hold

the

corrector lever against

the

block

gauge,

and

push

the

tension lever against

the stopper

pin,

press-fitted

into

the

pump

housing.

Next, push

the

sleeve

until

the

start

lever contacts

the

tension lever,

and

will

not

move

any

further.

Next, read

the

dial

and

select

the

proper

sized

closing plug,

to

ensure dimension

"MS"

is as

specified.

3-1-49

Loading...

Loading...