Chapter 3 Fuel Injection Equipment

9. Pump Reassembly, Adjustment and Inspection

,

4LHA Serie

14. Testing Governor Lever

Assembly

Movement

Position

the cam in the top dead end position,

and

manually check governor lever assembly

(control sleeve) movement. Perform this test

over

the entire cam profile.

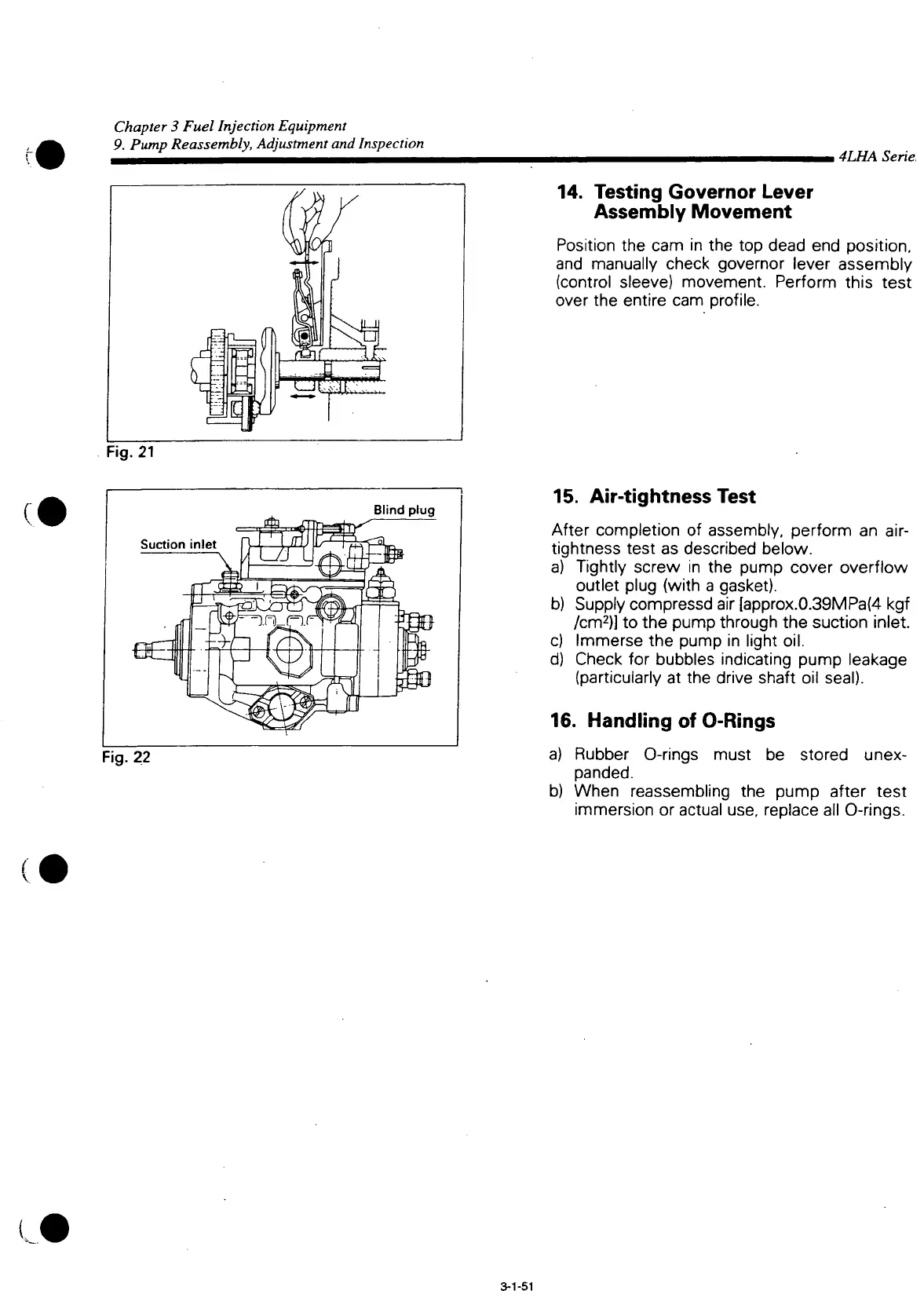

Fig.

21

Blind

plug

Suction

inlet

663

--

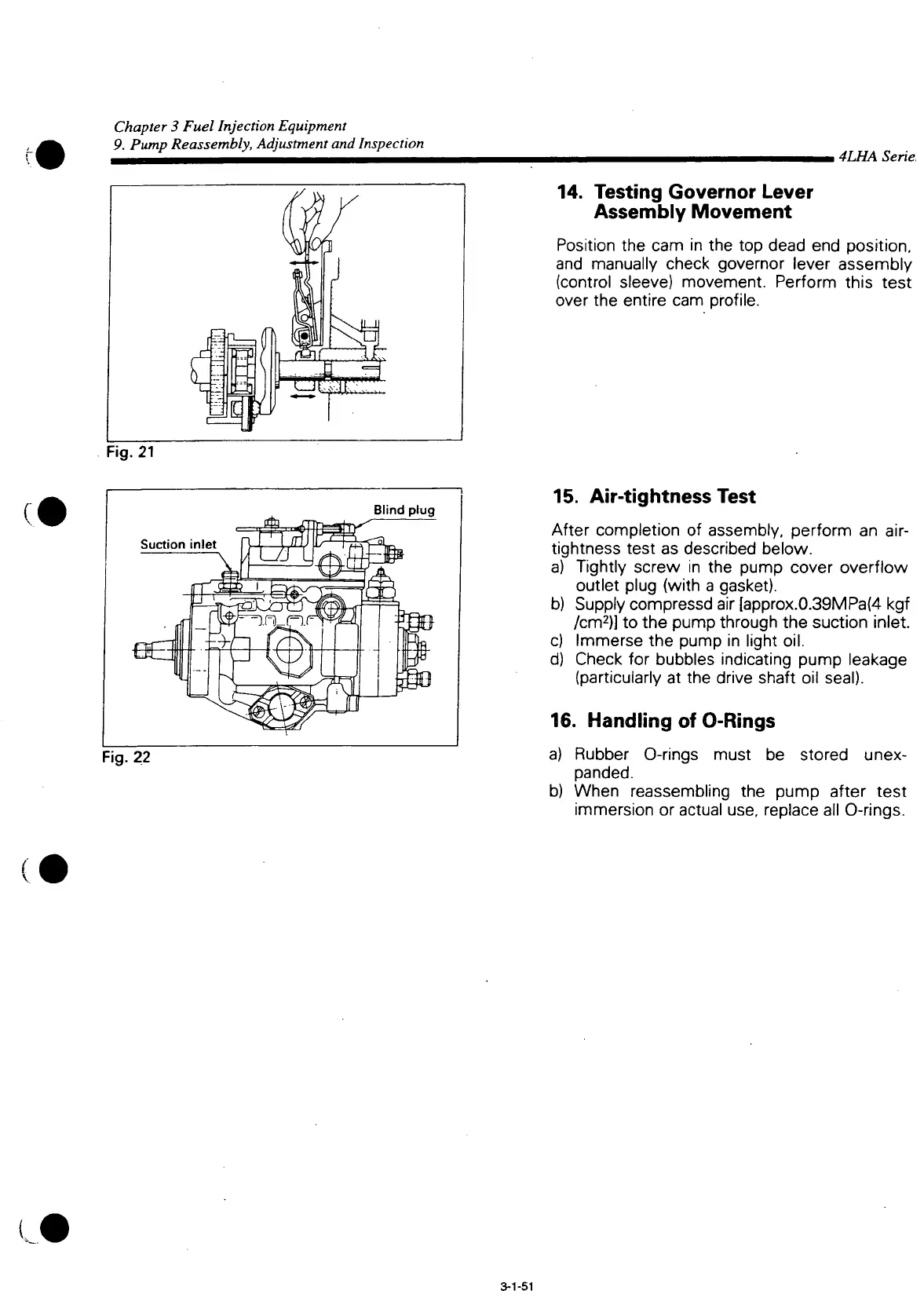

Fig.

22

15.

Air-tightness

Test

After completion of assembly, perform an air-

tightness test as described below.

a) Tightly screw in the pump cover overflow

outlet plug

(with

a gasket).

b) Supply

compressd

air [approx.0.39MPa(4 kgf

/cm

2

)]

to the pump through the suction inlet.

c) Immerse the pump in light oil.

d)

Check

for bubbles indicating pump leakage

(particularly at the drive shaft oil seal).

16.

Handling

of O-Rings

a) Rubber O-rings must be stored unex-

panded.

b) When reassembling the pump after test

immersion or actual use, replace all O-rings.

3-1-51

Loading...

Loading...