Chapter 3 Fuel Injection Equipment

10. Test Bench Adjustment of VE Pump

10.

Test

Bench

Adjustment

of VE

Pump

i

4LHA

Series

i

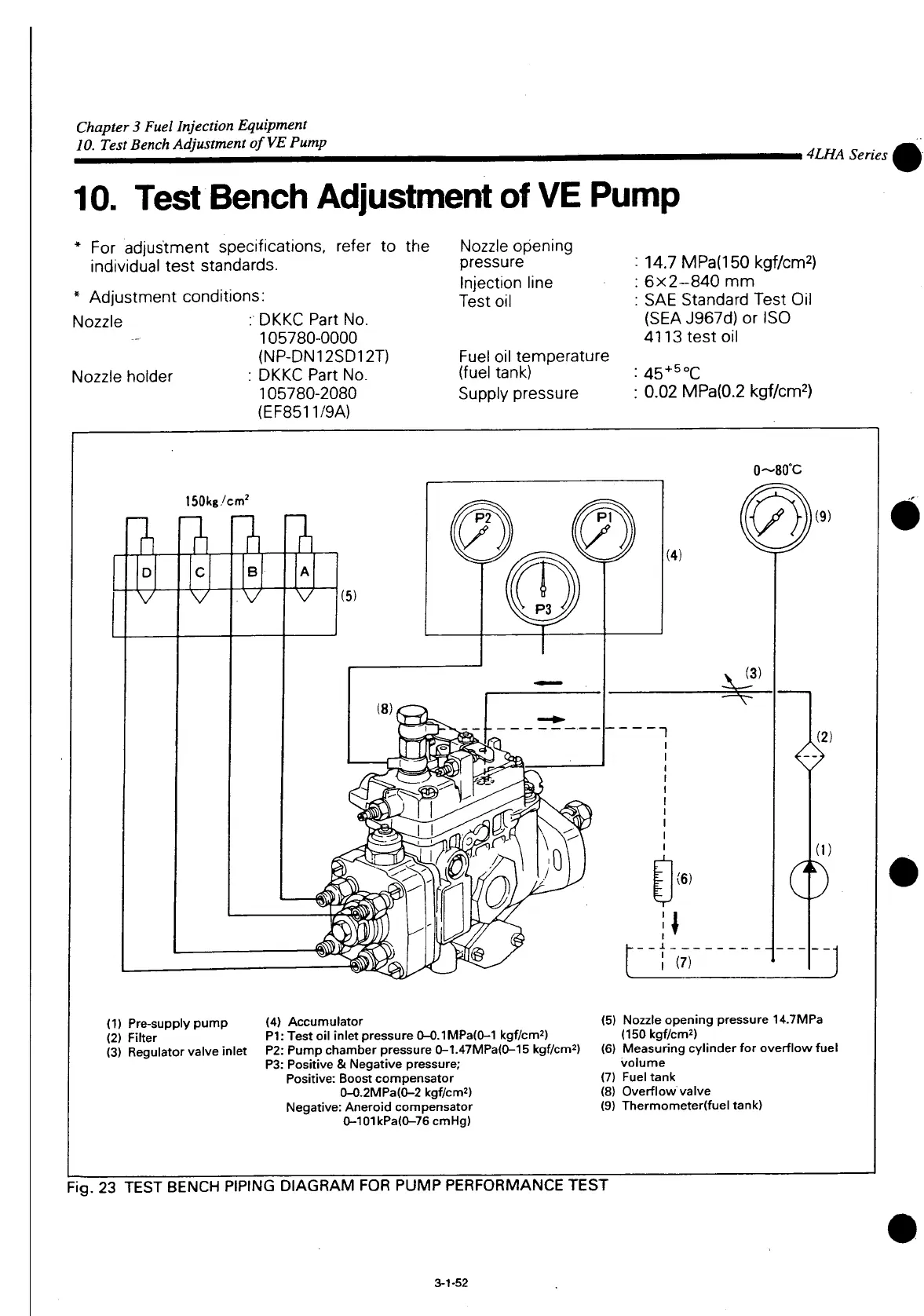

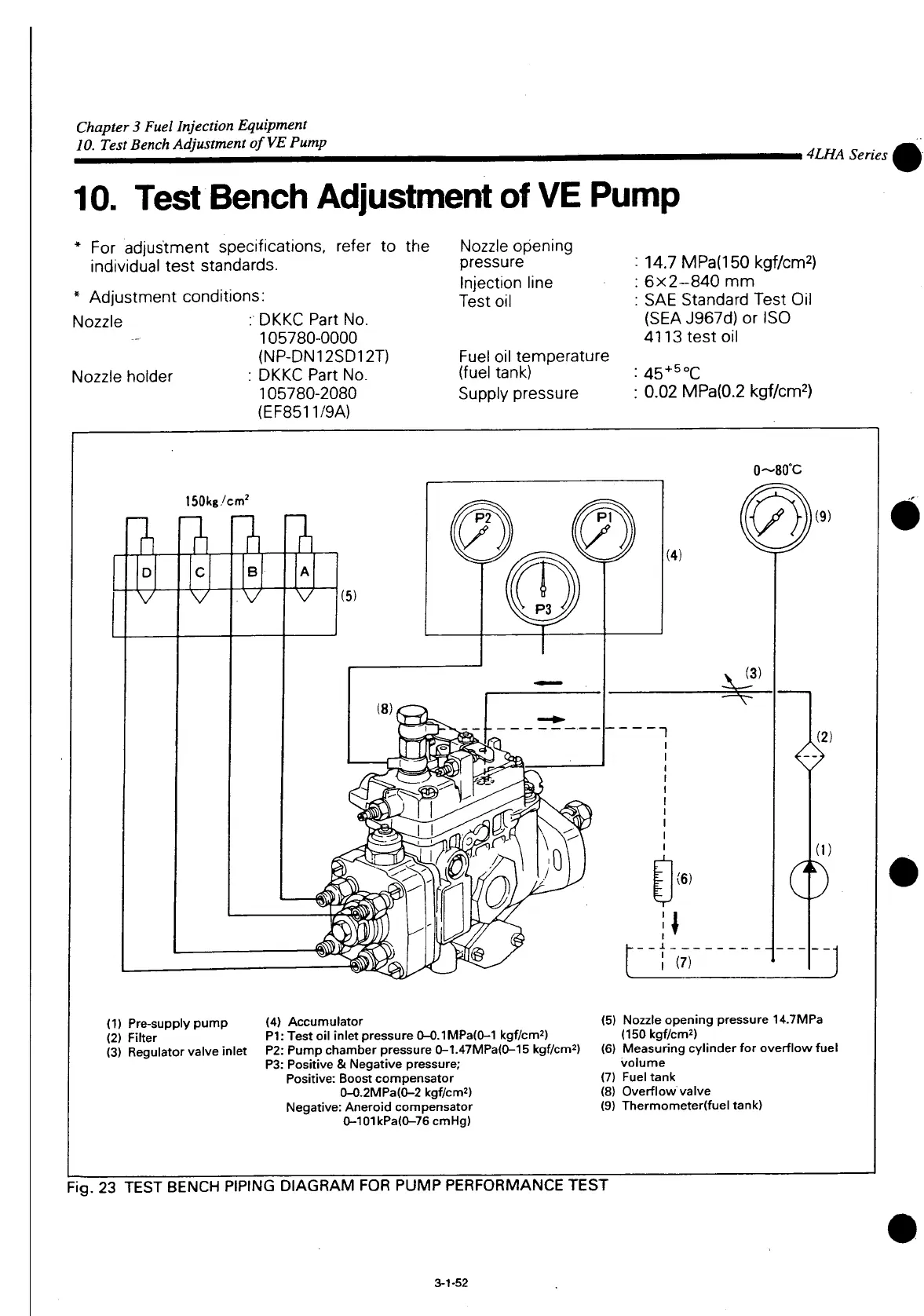

* For adjustment specifications, refer to the

individual test standards.

Adjustment conditions:

Nozzle

Nozzle

holder

DKKC

Part No.

105780-0000

(NP-DN12SD12T)

DKKC

Part No.

105780-2080

(EF8511/9A)

Nozzle

opening

pressure

Injection

line

Test oil

Fuel

oil temperature

(fuel

tank)

Supply pressure

14.7MPa(150

kgf/cm

2

)

6x2-840 mm

SAE

Standard Test Oil

(SEAJ967d)

or ISO

4113 test oil

45

+5o

C

0.02 MPa(0.2 kgf/cm

2

)

0~80°c

150kg/cm

2

(1) Pre-supply pump

(2) Filter

(3) Regulator valve

inlet

(4) Accumulator

PI:

Test oil

inlet

pressure 0-0.1MPa(0-1 kgf/cm

2

)

P2:

Pump chamber pressure 0-1.47MPa(0-15 kgf/cm

2

)

P3:

Positive & Negative pressure;

Positive:

Boost compensator

0-0.2MPa(0-2 kgf/cm

2

)

Negative: Aneroid compensator

0-101kPa(0-76 cmHg)

(5) Nozzle opening pressure 14.7MPa

(150 kgf/cm

2

)

(6) Measuring cylinder for overflow fuel

volume

(7) Fuel

tank

(8) Overflow valve

(9) Thermometer(fuel

tank)

Fig.

23

TEST

BENCH

PIPING

DIAGRAM

FOR

PUMP

PERFORMANCE

TEST

3-1-52

Loading...

Loading...