Chapter 3 Fuel Injection Equipment

4. Adjustment of Fuel Injection Pump and Governor

4LHA Series

Pump

rpm (N4)

200 rpm

Rack

indicator

scale

13.5

~ 14.5

Measuring

stroke

500st

Injection volume

See separate service

data

4-75 Check

injection

stop

Drive the pump at no load maximum rpm (N

2

). With

governor control lever in the

full

load position, operate

the stop lever on the governor

case,

and make sure

that

injection to all cylinders is stopped.

4-8

Adjustment

of

torque

rise

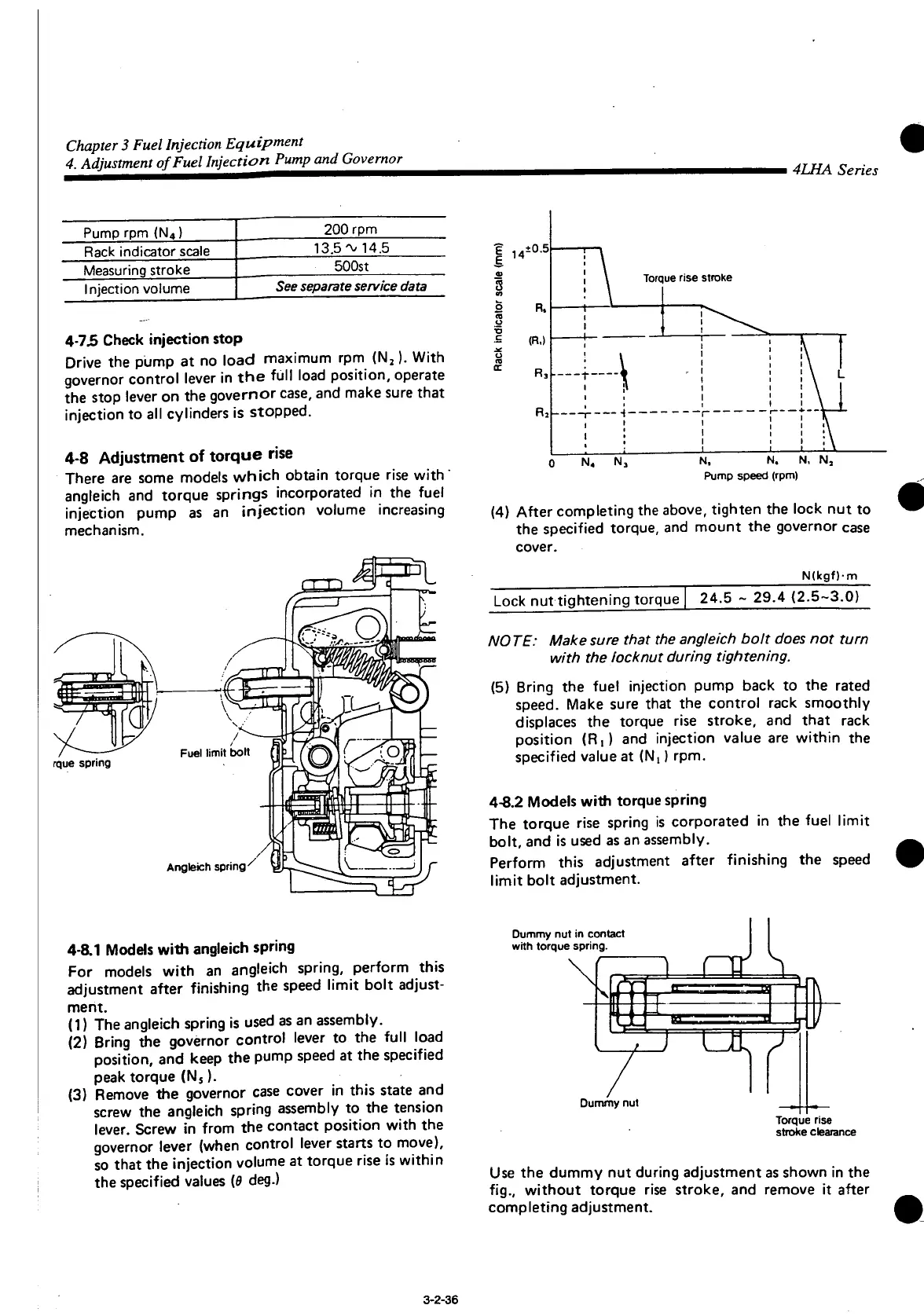

There

are some models which obtain torque rise

with

angleich

and torque springs incorporated in the fuel

injection pump as an injection volume increasing

mechanism.

Angleich

spring

I

14

±0.5

•o

R.

(R.)

R3

Torque rise stroke

N,

N. N, Nj

Pump

speed (rpm)

(4) After completing the above, tighten the lock nut to

the specified torque, and mount the governor

case

cover.

N(kgf)m

Lock

nut tightening torque

24.5 ~ 29.4

(2.5-3.0)

NO TE: Make sure that the angleich bolt does not turn

with the locknut during tightening.

(5) Bring the fuel injection pump back to the rated

speed.

Make sure

that

the control rack smoothly

displaces

the torque rise stroke, and

that

rack

position (R,) and injection value are within the

specified

value at (N!) rpm.

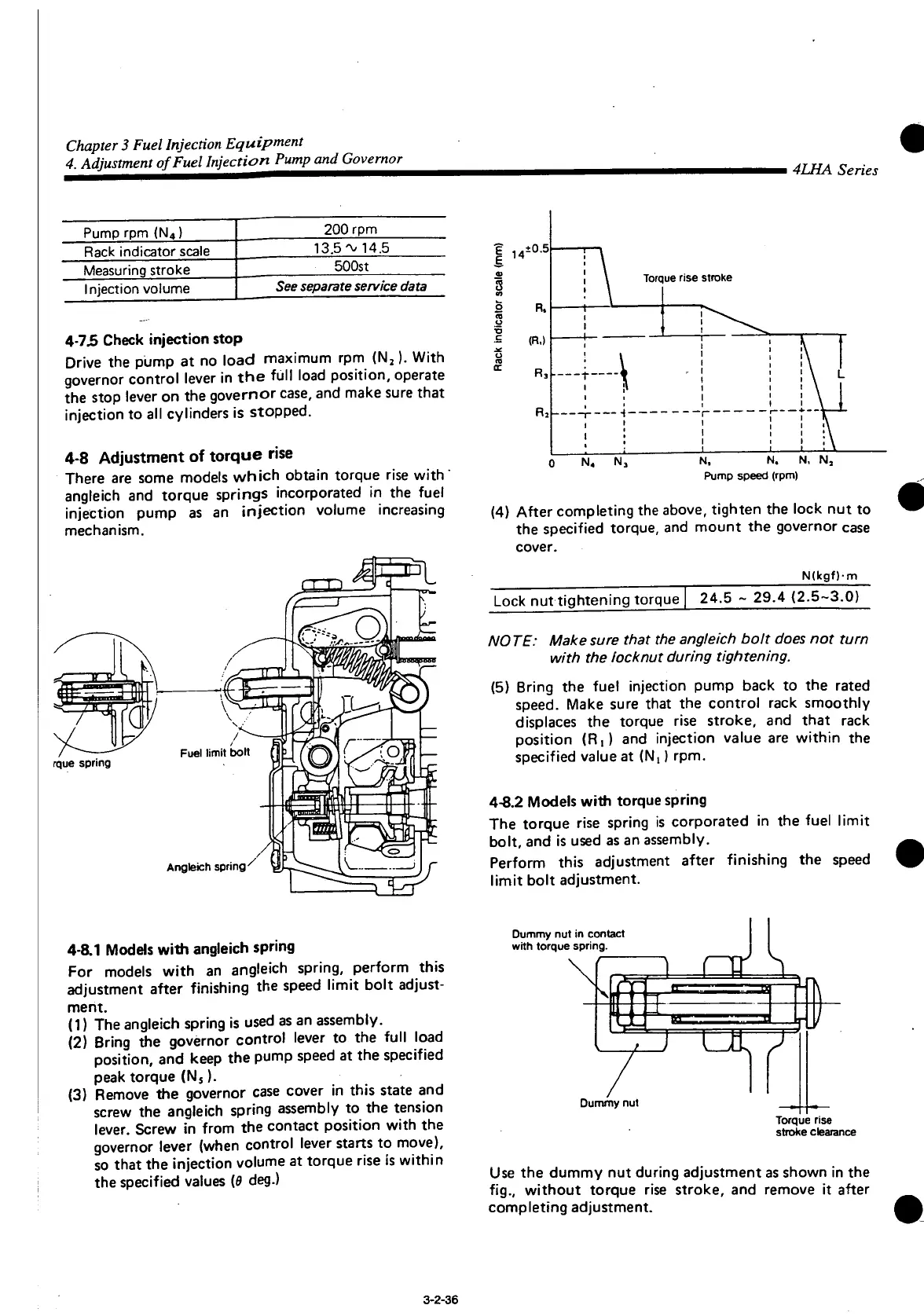

4-8.2 Models

with

torque spring

The

torque rise spring is corporated in the fuel

limit

bolt, and is used as an assembly.

Perform

this adjustment after finishing the speed

limit

bolt adjustment.

4-8.1 Models

with

angleich

spring

For

models

with

an angleich spring, perform this

adjustment after finishing the speed

limit

bolt adjust-

ment.

(1) The angleich spring is used as an assembly.

(2) Bring the governor control lever to the

full

load

position,

and keep the pump speed at the specified

peak

torque (N

5

).

(3) Remove the governor

case

cover in this state and

screw

the angleich spring assembly to the tension

lever.

Screw in from the contact position

with

the

governor lever (when control lever starts to move),

so

that

the injection volume at torque rise is within

the specified values [8 deg.)

Dummy nut in contact

with

torque spring.

J UL J

Dummy nut

Torque rise

stroke clearance

Use

the dummy nut during adjustment as shown in the

fig.,

without torque rise stroke, and remove it after

completing adjustment.

3-2-36

Loading...

Loading...