Chapter 3 Fuel Injection Equipment

6. Fuel Feed Pump

4LHA Seriesy

6-5

Fuel

Feed

Pump Adjustment

1. Testing procedures for the fuel feed pump

Set

the fuel feed pump on the injection pump, and

operate the assembled

unit

on the pump tester.

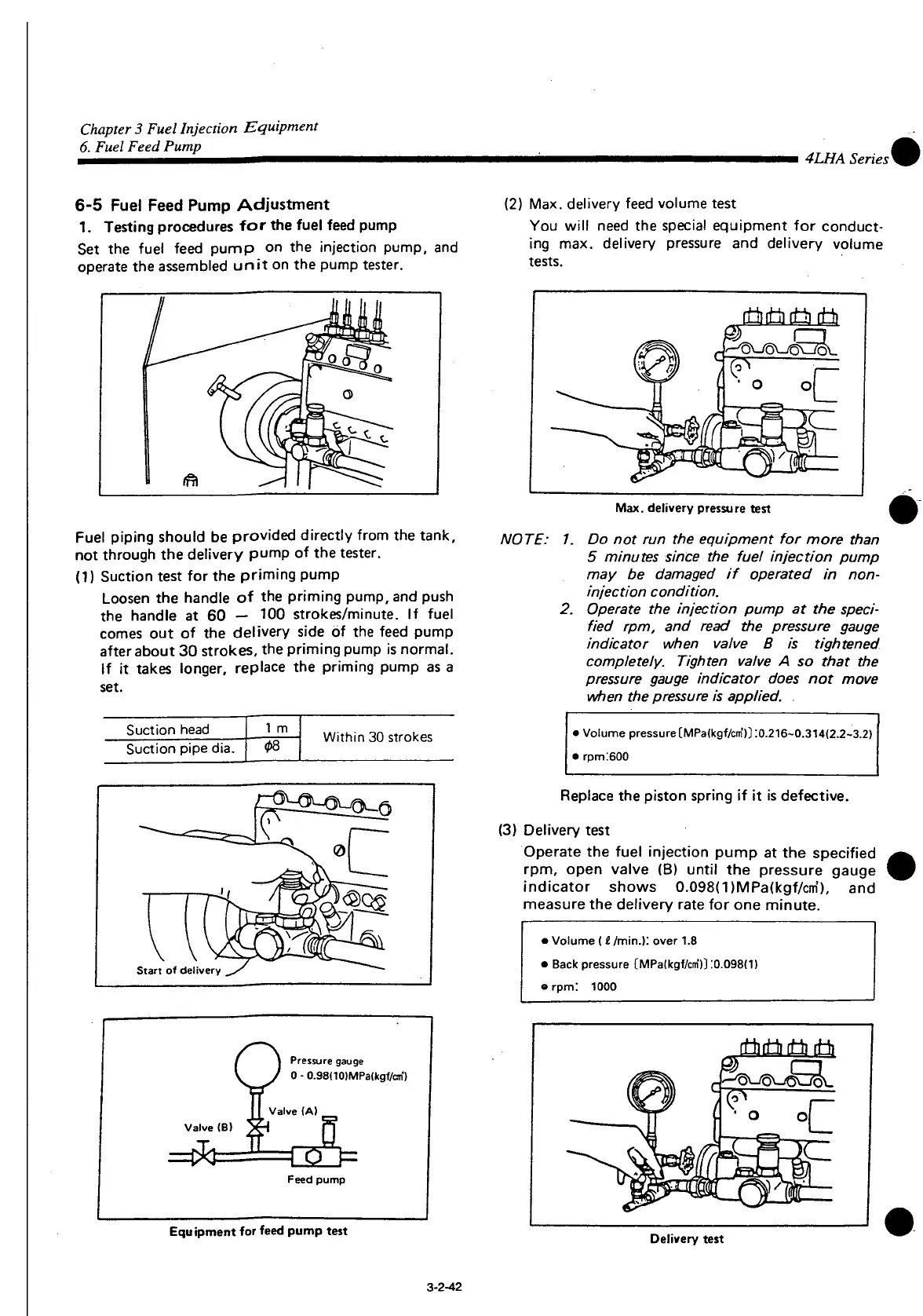

(2) Max. delivery feed volume test

You

will

need the

special

equipment for conduct-

ing max. delivery pressure and delivery volume

tests.

Fuel

piping should be provided directly

from

the tank,

not through the delivery pump of the tester.

(1) Suction test for the priming pump

Loosen

the handle of the priming pump, and push

the handle at 60 — 100 strokes/minute. If fuel

comes

out of the delivery side of the feed pump

after about 30 strokes, the priming pump is normal.

If it takes longer, replace the priming pump as a

set.

Max.

delivery pressure test

NOTE: 1. Do not run the equipment for more than

5 minutes since the fuel injection pump

may be damaged if operated in non-

injection condition.

2. Operate the injection pump at the speci-

fied rpm, and read the pressure gauge

indicator when valve B is tightened

completely. Tighten valve A so that the

pressure gauge indicator does not move

when the pressure is applied.

Suction

head

Suction

pipe dia.

1 m

Within 30 strokes

>

Volume pressure[MPa(kgf/cm')]:0.216-0.314(2.2-3.2)

• rpm:600

Replace

the piston spring if it is defective.

(3) Delivery test

Operate

the fuel injection pump at the specified

rpm,

open valve (B)

until

the pressure gauge

indicator shows

0.098(1

)MPa(kgf/cm), and

measure

the delivery rate for one minute.

• Volume (t /min.): over 1.8

•

Back

pressure (MPa(kgf/cm')] :0.098(1)

»rpm:

1000

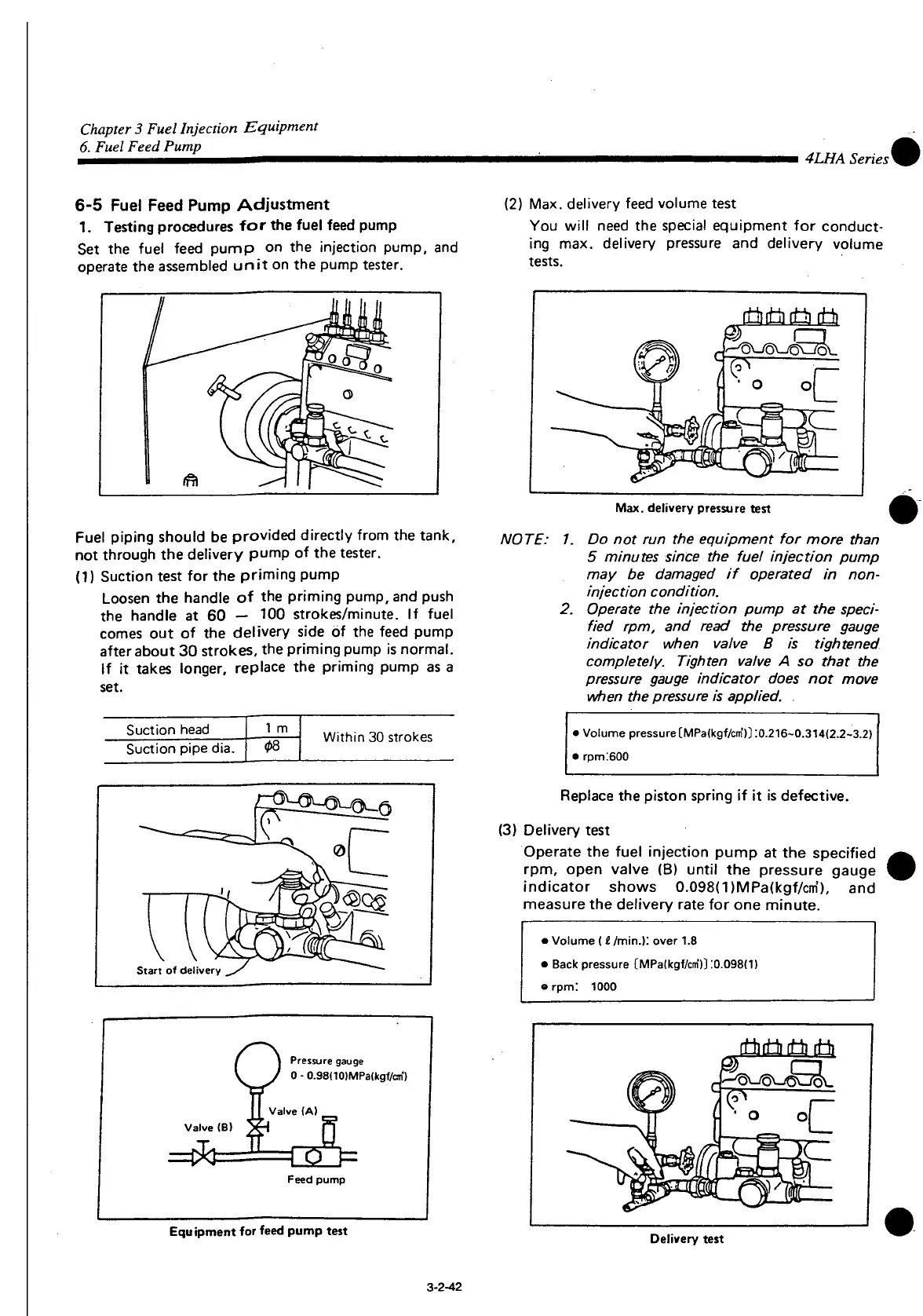

O

Pressure

gauge

0 - 0.98(10)MPa(kgf/cin)

Valve

(B)

Valve

(A).

Feed

pump

Equipment for feed pump test

Delivery

test

3-2-42

Loading...

Loading...