6 YASKAWA TM.A1000SW.063 Spindle Orientation A1000 Custom Software Supplement

2 Spindle Orientation

2 Spindle Orientation

Overview

The target applications for this function are on equipment that must stop in specific positions including tool changing for

machine tool spindles and die changing for punch/stamping presses. This software also provides automatic switchover to

closed-loop operation at low speed.

Applicable Models

This Spindle Orient software is available for the drive models listed in Table 1.

Table 1 Applicable Models

Basic Concepts and Principles

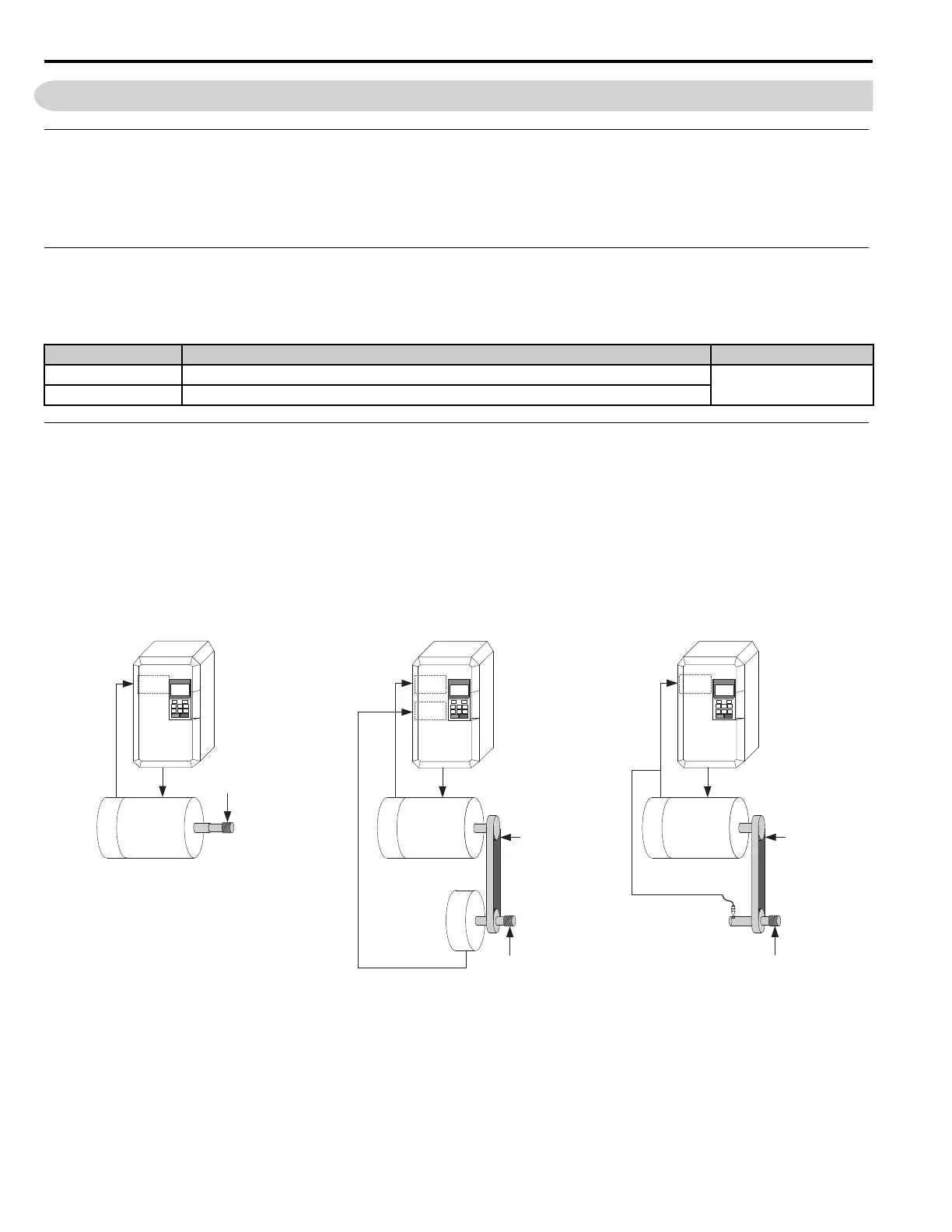

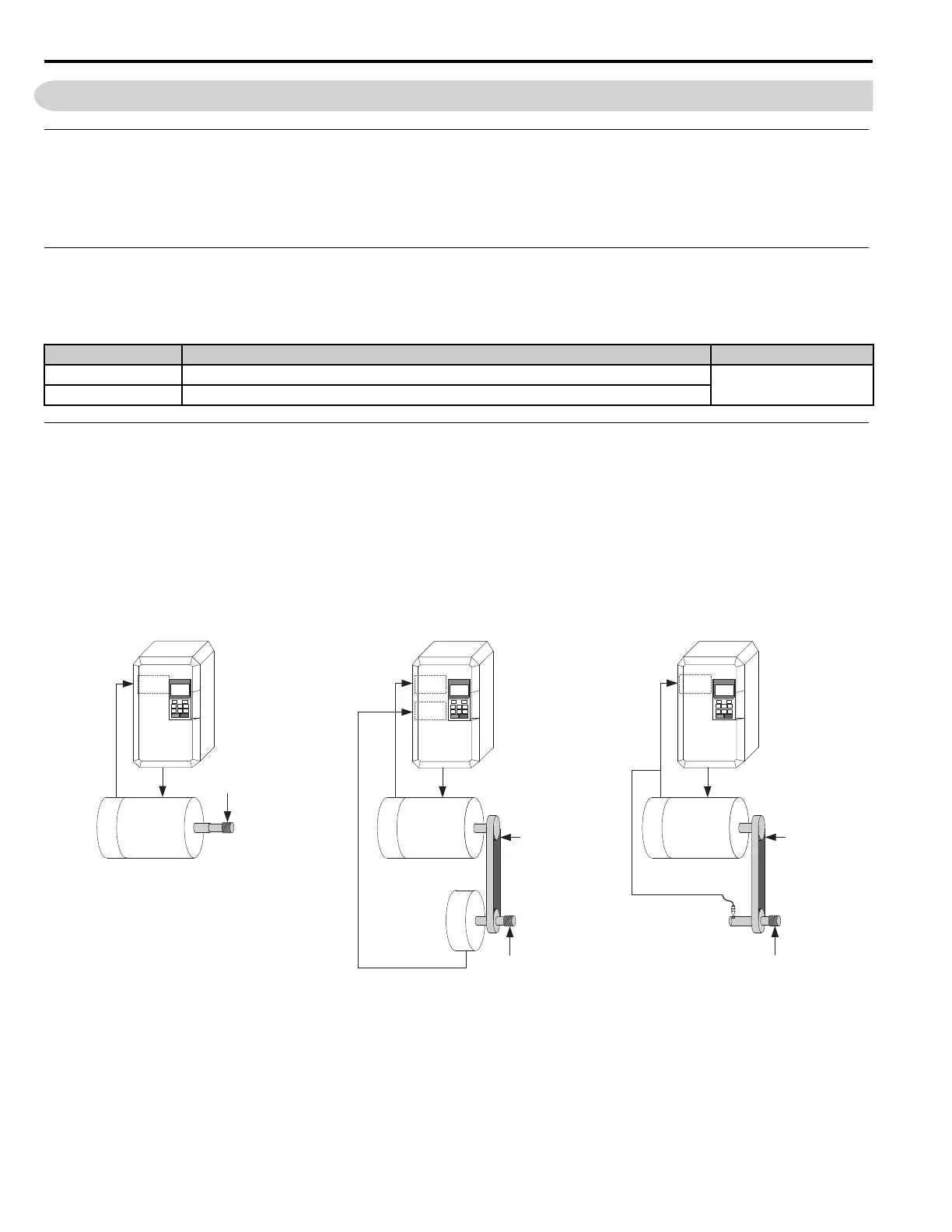

This orientation software allows an A1000 drive to repeatedly stop a machine at a certain point in its rotational cycle. This

is accomplished by means of an orientation encoder directly coupled to the machine part to be positioned. A simple

example is to think of the hands on a clock. If the orientation encoder is mounted to the motor shaft, this software can stop

the motor so that the spindle stops at the 3 o'clock position every time. Application configurations are outlined in

Figure 1. For configurations other than those outlined, contact Yaskawa Application Engineering before applying this

software.

Figure 1

Figure 1 Spindle Orientation Hardware Configurations

Voltage Class Model Software Version

200 V CIMR-AU2A0004A-063 to CIMR-AU2A0415A-063

VSA91009x

400 V CIMR-AU4A0002A-063 to CIMR-AU4A0250A-063

Motor

Encoder

Machine

Motor

Configuration2:IndirectDrivewith

OrientationEncoder

Configuration1:DirectDrive

PG-X3

PG-X3

PG-X3

Orientated

MachinePart

Orientation

Encoder

Orientated

MachinePart

Drivetrain

(GearRatio)

CN5-B

CN5-C

CN5-C

Motor

Encoder

ChA/B/Z

ChA/B/Z

ChA/B

Machine

Motor

Motor

Encoder

Machine

Motor

Configuration3:IndirectDrivewith

ProximitySensor

PG-X3

Proximity

Sensor

Orientated

MachinePart

Drivetrain

(GearRatio)

CN5-C

ChZ

ChA/B

Loading...

Loading...