3.3 Message Communication Error

3.3.3 Checking the Message Function

3-13

3

Troubleshooting Errors in Message Communication

3.3.3 Checking the Message Function

If message communication with the PLC or touch panel of another manufacturer or the computer does not start, the

details of the error can be determined by checking the process result of the message function and the status.

The procedures for checking the process result of the message function, status, and parameter settings are given below.

( 1 ) Checking the Process Result and the Status

The process result of the message function and the status can be checked by referring to the following parameters.

The procedures for checking the process result and the status and the associated remedies when using the message

transmission or message receive function are given below.

Use the register list of MPE720 to check the data of the registers.

Example: When DA00000 was specified as the start address of the parameter list

Parameter Details

Process Result (PARAM00)

Displays the error that has occurred during the execution of the message function.

This information is useful for troubleshooting the errors that occur when message function

parameters are not properly set.

Status (PARAM01)

This information is useful when the error “Communication section error (88xxH)”, whose

details cannot be determined with the process result (PARAM00), has occurred.

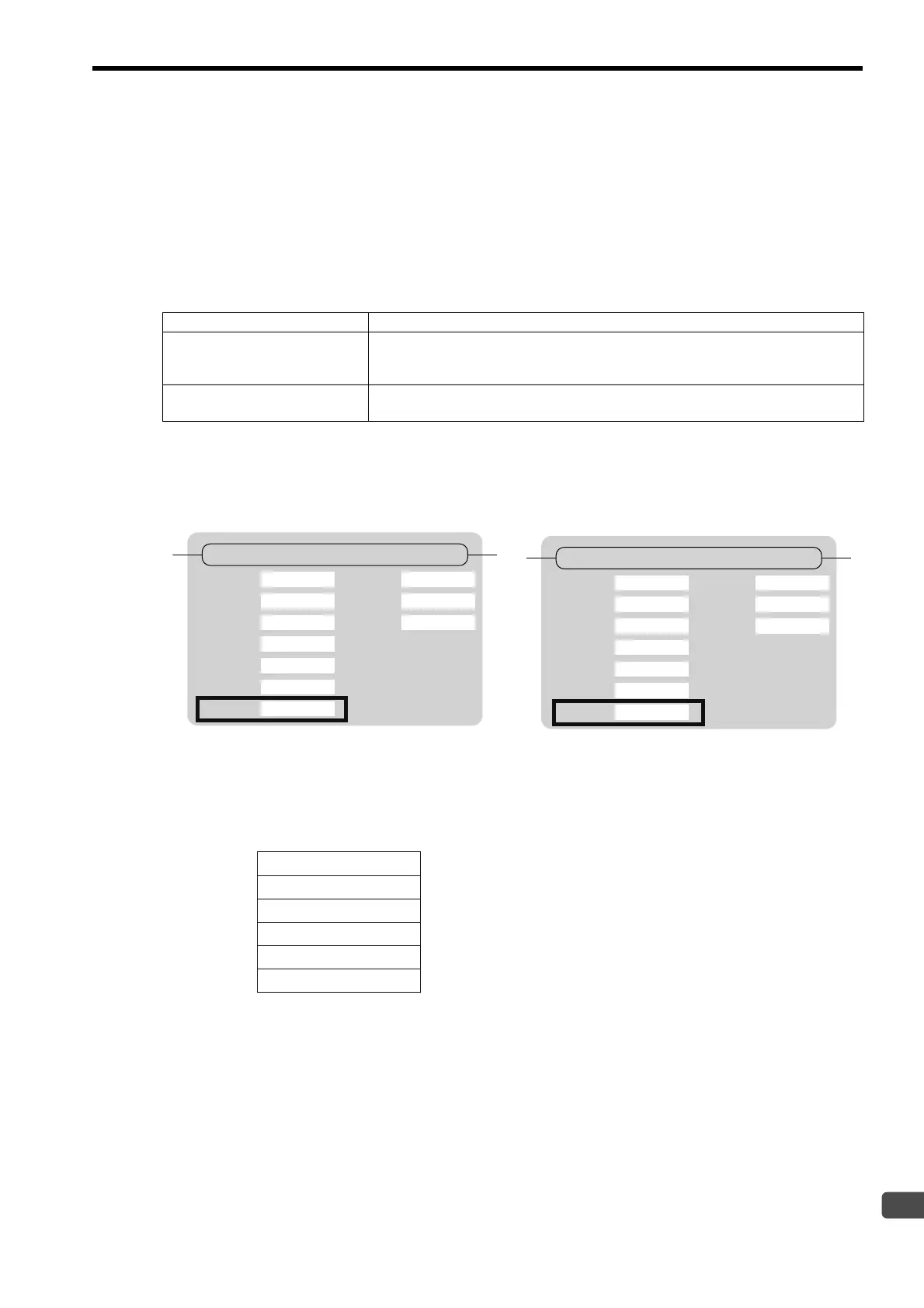

When using the message transmission function When using the message receive function

Execute

Abort

Dev-Typ

Pro-Typ

Cir-No

Ch-No

Param

MSG-SND

Busy

Complete

Error

DA00000

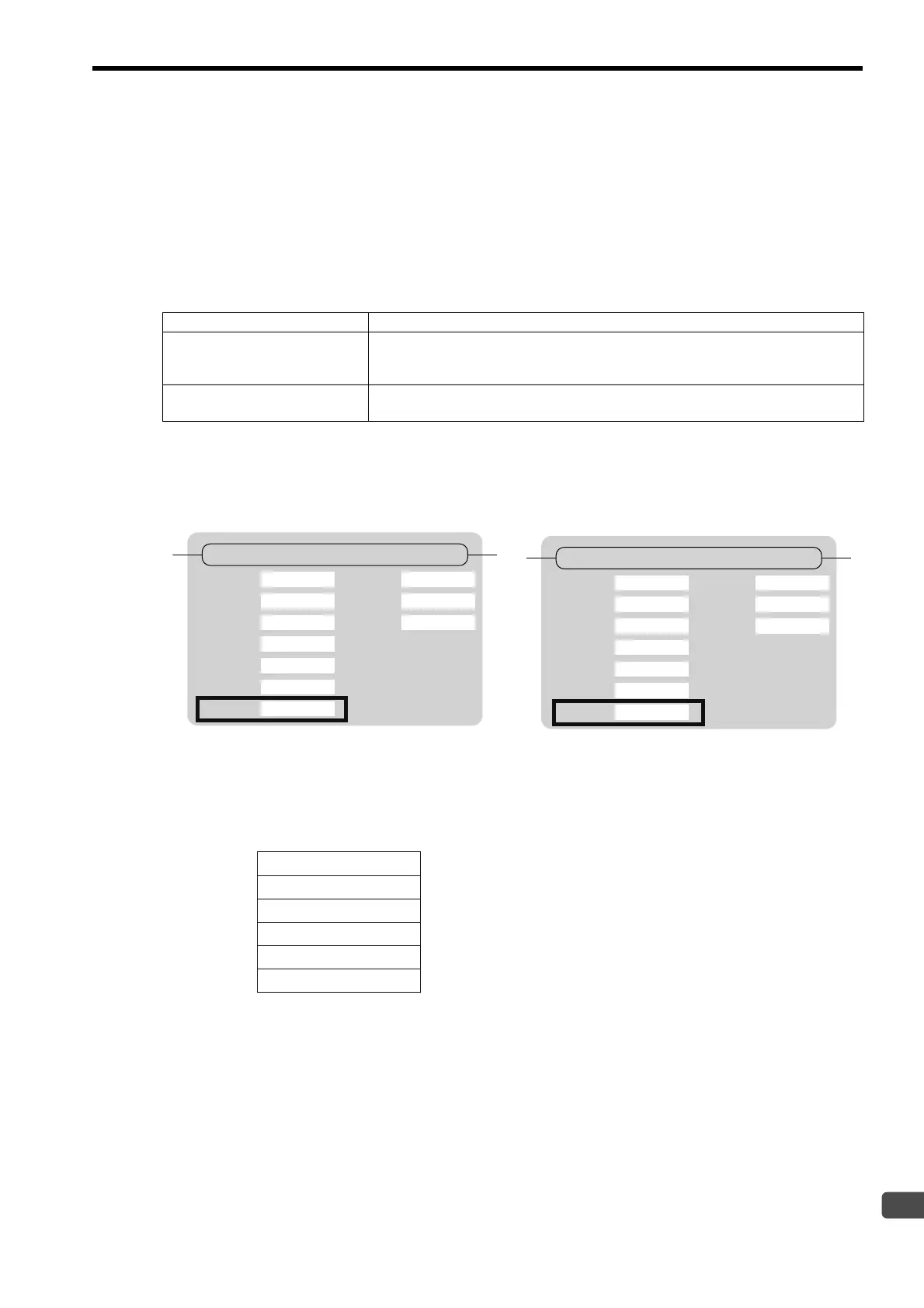

Execute

Abort

Dev-Typ

Pro-Typ

Cir-No

Ch-No

Param

MSG-RCV

Busy

Complete

Error

DA00000

Parameter List

Register F 0

DW00000

(1) Process result

DW00001

(2) Status

PARAM00

PARAM01

Loading...

Loading...