Using Inverters for Elevating Machines

6-175

If the mechanical operation of the holding brake is slow, use the dwell function at start to prevent brake wear,

and accelerate after the brake is completely open.

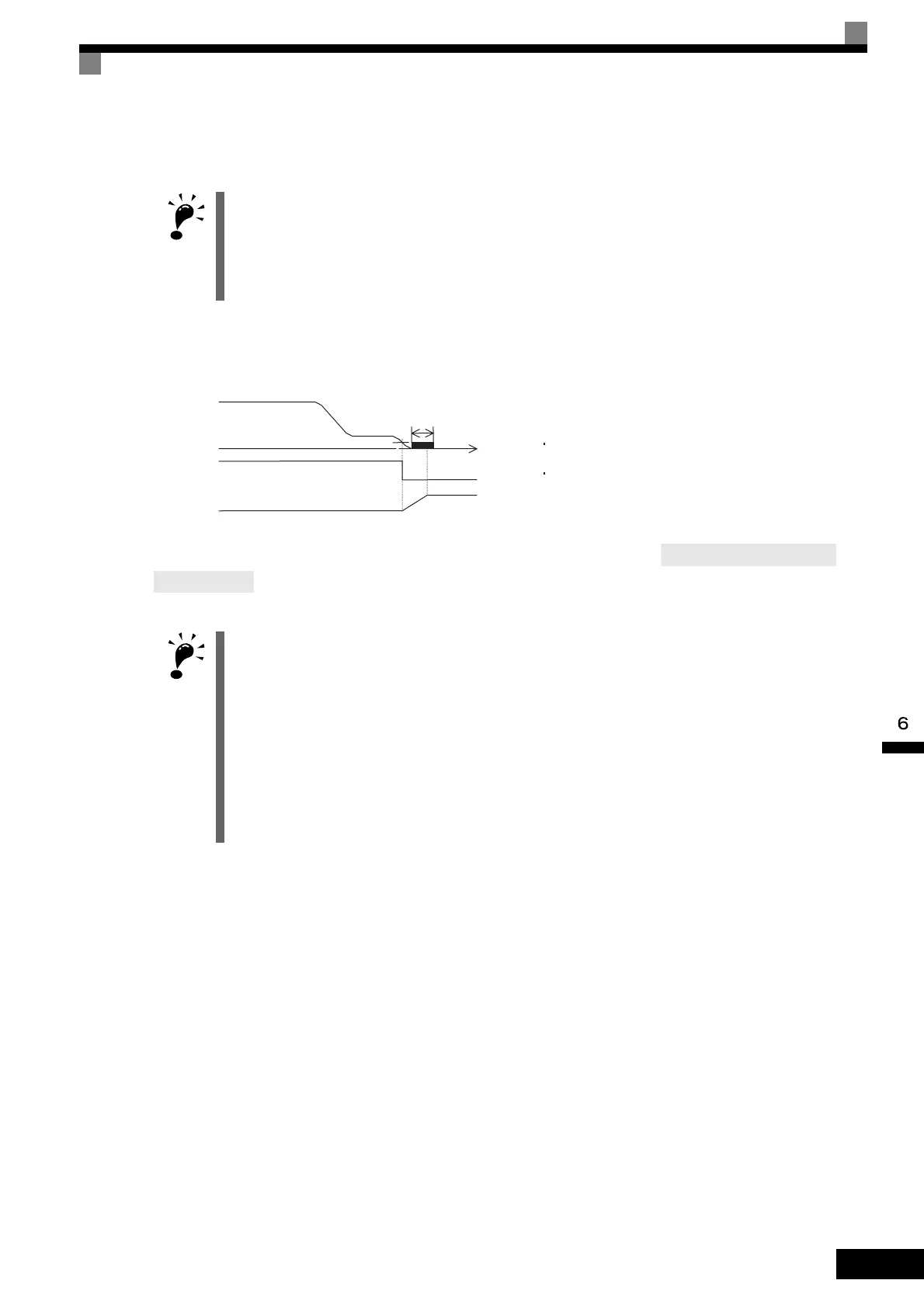

Stopping with DC Injection Braking and Zero-speed Control

When the holding brake’s mechanical operation is slow, use DC injection braking

until the brakes are fully closed to prevent the brakes from slipping when stopping.

Torque Compensation (Flux Vector Control Only) (SPEC: E or Later Only)

When flux vector control is used, the torque compensation signals corresponding to the load can be input from

the multi-function analog input terminals in advance to reduce shock, such as that caused by opening and clos-

ing holding brakes. The load size and motoring/regenerating status must be detected at the machine side in

advance. Check that polarity is correct. Incorrect polarity will increase the shock.

IMPORTANT

1. When using open-loop vector control and V/f control, set b6-01 (Dwell frequency at start) higher than fre-

quency detection 2 (frequency when brakes open).

2. If the motor tends to have insufficient torque when started, use the DC injection braking function to allow

sufficient motor current (torque) before starting.

• b2-03 (DC injection braking time at start): 0.2 to 0.5 s

• b2-02 (DC injection braking current): 50% to 80% (open-loop vector control, V/f control only)

IMPORTANT

1. When the load cannot be maintained sufficiently using DC injection braking with open-loop vector control

and V/f control, use the dwell functions at stop.

• b6-03 (Dwell frequency at stop): Min. output frequency to 3.0 Hz.

The value must be less than the frequency when frequency detection 2 is OFF (L4-01 − L4-02).

• b6-04 (Dwell time at stop): 0.3 to 0.5 s

[b2-04 (DC injection braking at stop): 0.0 s]

2. If the Inverter and motor must be isolated while stopping using a magnetic contactor, for example in an ele-

vator, fully close the holding brakes and isolate the Inverter during baseblock (during baseblock signal: ON)

as stipulated by law in the EU.

During motor control or DC injection braking (zero-speed control), an Inverter error may occur due to surge

voltage. When a magnetic contactor is used between the Inverter and motor, set L8-07 (Output open-

phase protection) to 1 (enabled).

b2-04 (DC injection braking time at stop

(zero-speed control time at stop): 0.3 to 0.5 s

(HIGH)

t

Output frequency

Holding brake operation

ON OFF

CLOSE

OPEN

(LOW)

b2-01 [Zero speed level (DC injection braking

starting frequency)]: 0.1 to 3.0 Hz

b2-02 (DC injection braking current): 50% to 80%

(open-loop vector control, V/f control only)

Frequency

detection 2 or

During run 2

(zero-speed control for flux

vector control)

Loading...

Loading...