APPENDIX 2 LIST OF PARAMETER NUMBERS (Co~fd)

,6,15;~“r

‘~ ~“~

I).

_ ... .— .—

-L—.. ,

AT SUPZ, ATSUPX Dl, DO

Specify whether or not the Automatic Coordinate

System Setting is effective on the Z- and X-axis,

respectively.

].:

Effective

0: Ineffective

Note :

The Automatic Coordinate System is

established with the following parameters:

Inch system:

#6631, #6630

Metric system: #6637, #6636

.——— ——

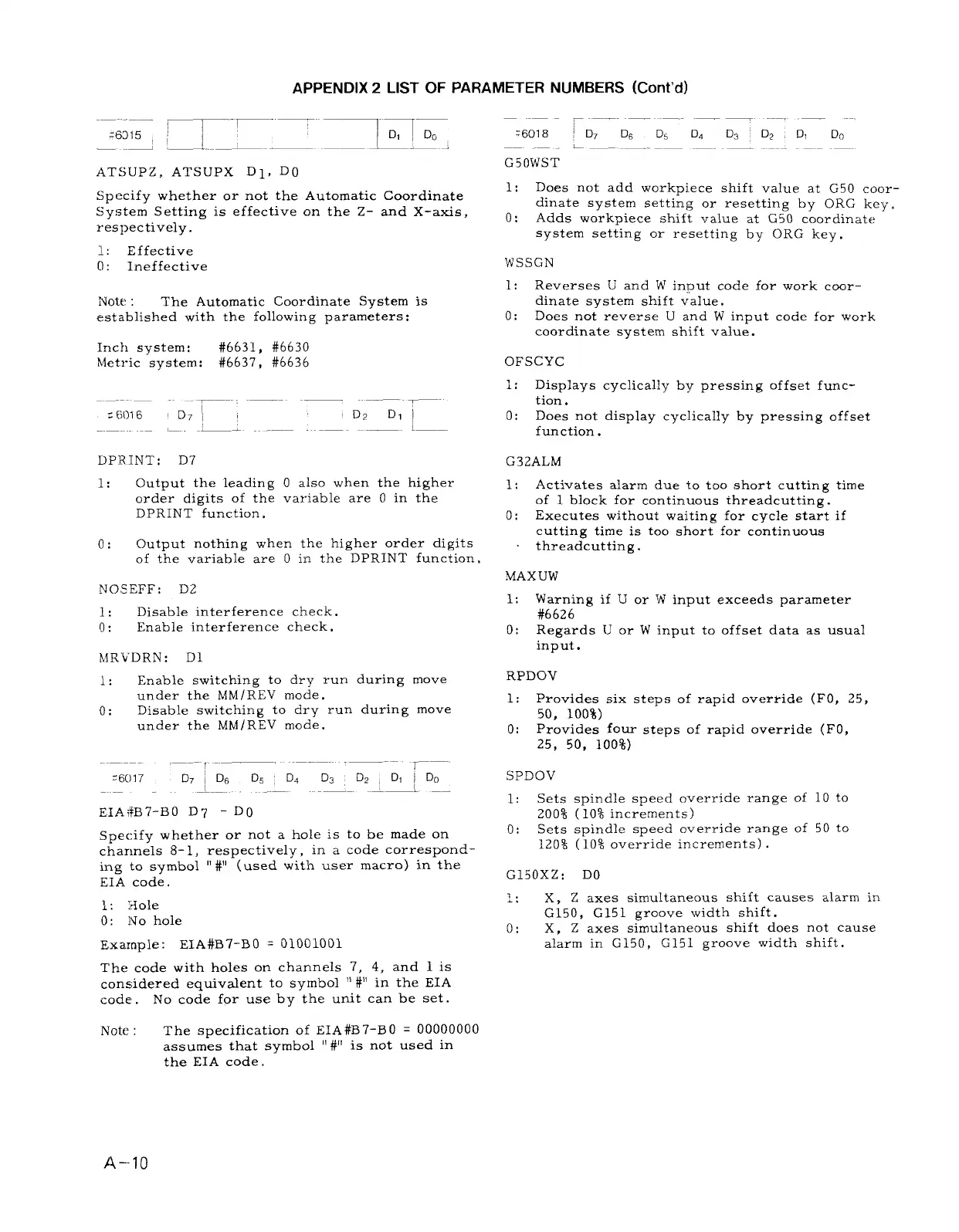

Z 6016

I

D711

,—. .— -——.

DPR.lNT: D7

1: Output the leading

order digits of the

DPRINT function.

~—

D2

D, I

L—.

O also when the higher

variable are O in the

0:

Output nothing when the higher order digits

of the variable are ‘0in the DPRINT function .

NO SEFF: D2

1:

Disable interference check.

o:

Enable interference check,

MR’VDRN: D1

1:

Enable switching to dry run during move

under the MM/REV mode.

o:

Disable switching to dry run during move

under the MM IREV mode.

~—-

=6017 D71DGDS’DAD3D2

D, ~ Do

——.

—_L . .

EIA~#B7-BO D7 - D()

Specify whether or not a hole is to be made on

channels 8-1, respectively, in a code correspond-

ing

to symbol “#“ (used with user macro) in the

EIA code.

1:

Hole

o: N o hole

Example:

EIA#B7-Bo ‘ 01001001

The code with holes on channels 7, 4, and 1 is

considered equivalent to symbol “#’iin the EIA

code .

No code for use by the unit can be set.

Note : The specification of EIA#B7-BO = 00000000

assumes that symbol “#“ is not used in

the EIA code.

——

~

.— — –——..—

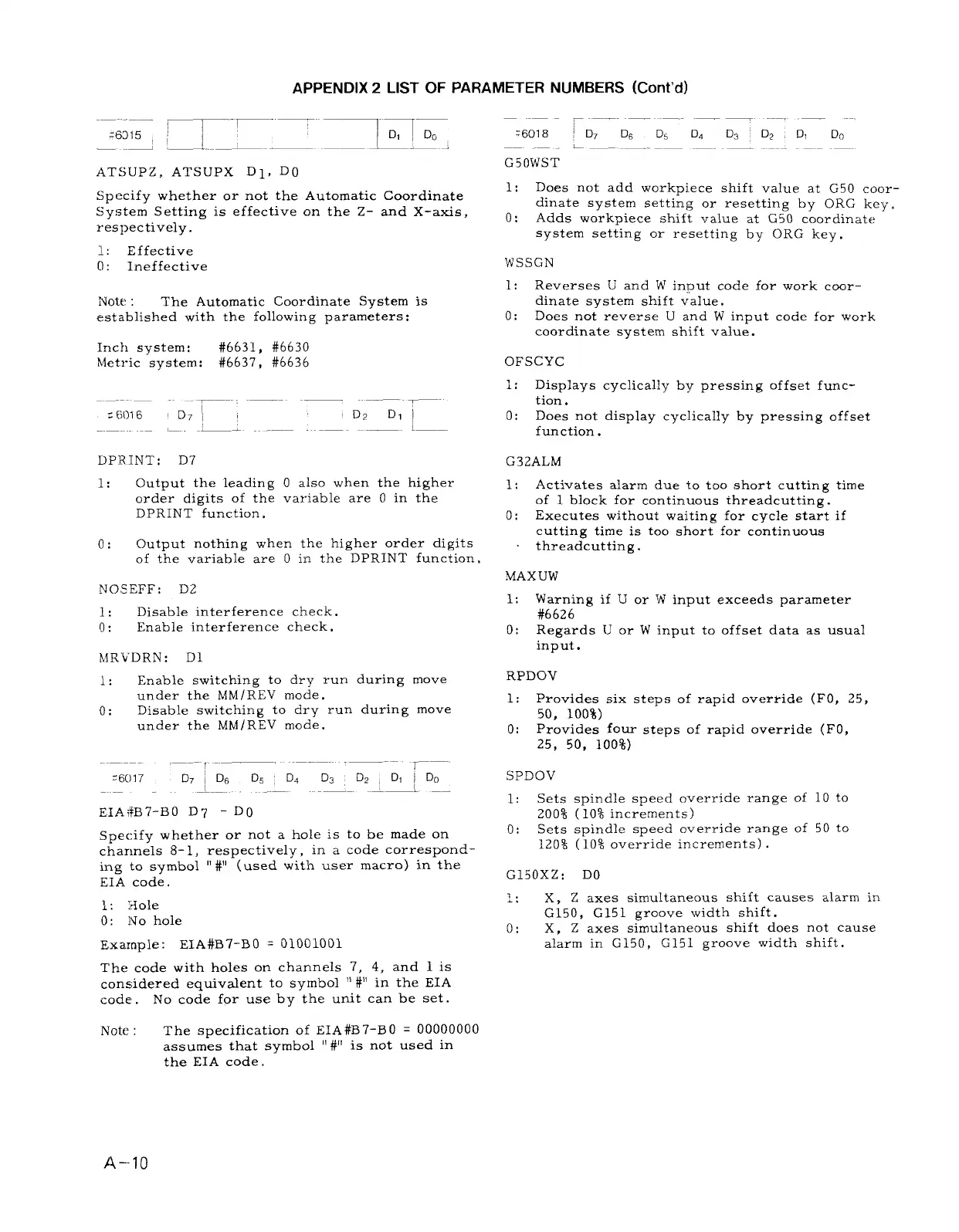

:6018

jD7D6D5DdD3 D2, DID0

,. __ __

G50WST

1:

Does not add workpiece shift value at G50 coor-

dinate system setting or resetting by ORG key.

o: Adds workpiece shift value at G50 coordinate

system setting or resetting by ORG key.

WSSGN

1: Reverses U and W input code for work coor-

dinate system shift value.

o: Does not reverse U and W input code for work

coordinate system s“hiftvalue.

OFSCYC

1: Displays cyclicallyby pressing offset func-

tion.

o:

Does not display cyclicallyby pressing offset

function.

G32ALM

1: Activates alarm due to too short cutting time

of 1 block for continuous ihreadcutting.

o:

Executes without waiting for cycle start if

cutting time is too short for continuous

threadcutiing.

MAX UW

1:

Warning if U or w input exceeds parameter

#6626

o: Regards U or W input to offset data as usual

input.

RPDOV

1:

Provides six steps of rapid over~ide (FO, 25,

50, 100%)

o:

Provides four steps of rapid override (FO,

25, 50, 100%)

SPDOV

1:

Sets spindle speed override range of 10 to

200% (10% increments)

o:

Sets spindle speed override range of 50 to

120% (10% override increments) .

G150XZ: DO

L: X, Z axes simultaneous shift causes alarm in

G150, G151 groove width shift.

o:

X, Z axes simultaneous shift does not cause

alarm in G150, G151 groove width shift.

A--1O

Loading...

Loading...