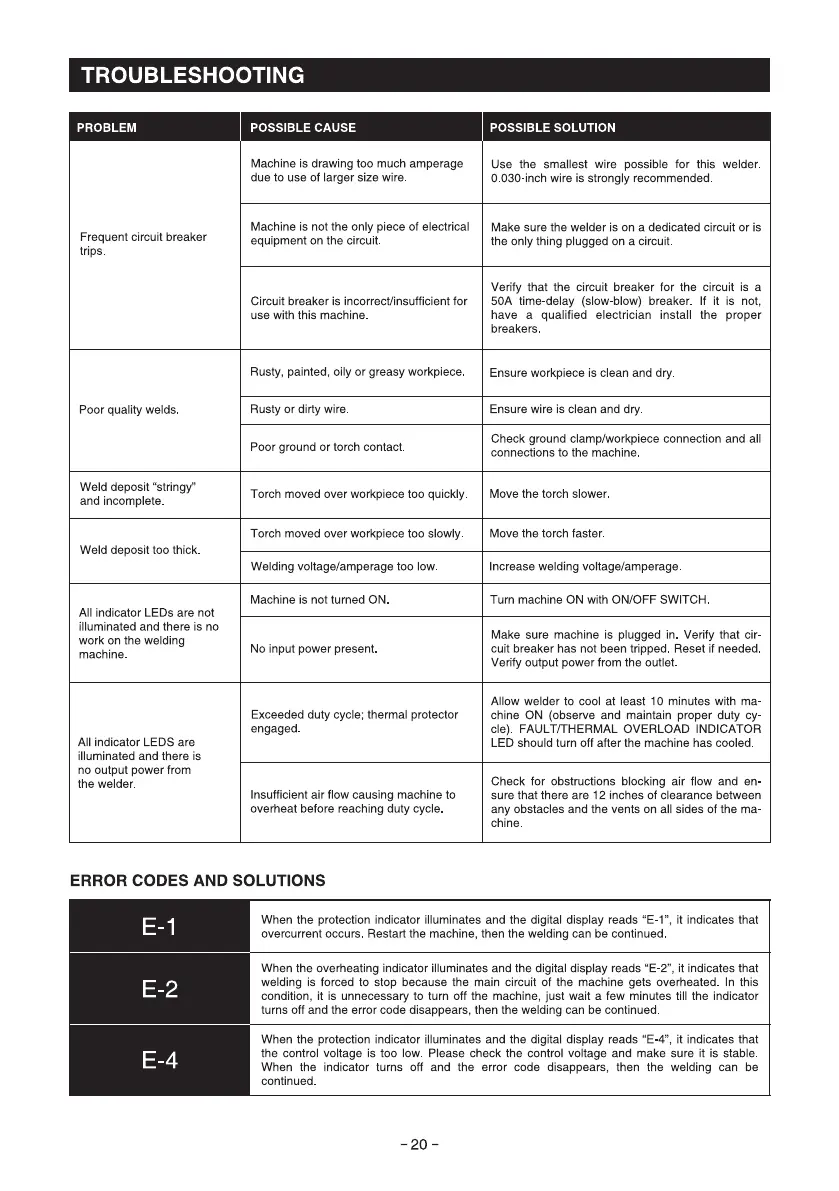

TROUBLESHOOTING

PROBLEM

Frequent circuit breaker

trips

Poor quality welds

Weld deposit "stringy'

and incomplete.

Weld deposit too thick

All indicator LEDs are not

illuminated and there is no

work on the welding

machine.

All indicator LEDS are

illuminated and there is

no output power from

the welder.

POSSIBLE CAUSE

Machine is drawing too much amperage

due to use of larger size wire.

Machine is not the only piece of electrical

equipment on the circuit.

Circuit breaker is incorrect"nsufficient for

use with this machine

Rusty, painted, oily or greasy workpiece

Rusty or dirty wire

Poor ground or torch contact

Torch moved over workpiece too quickly.

Torch moved over workpiece too slowly

Welding voltage/amperage too low

Machine is not turned ON

NO input power present.

Exceeded duty cycle; thermal protector

engaged

Insufficient air flow causing machine to

overheat before reaching duty cycle

POSSIBLE SOLUTION

Use the smallest wire possible for this welder

0 030-inch wire is strongly recommended.

Make sure the welder is on a dedicated circuit or is

the only thing plugged on a circuit

Verify that the circuit breaker for the circuit is a

50A time-delay (slow-blow) breaker If it is not,

have a qualified electrician install the proper

breakers

Ensure workpiece is clean and dry

Ensure wire is clean and dry

Check ground clamp/workpiece connection and all

connections to the machine.

Move the torch slower

Move the torch faster

Increase welding voltage/amperage

Turn machine ON with ON,'OFF SWITCH

Make sure machine is plugged in Verify that cir-

cuit breaker has not been tripped. Reset if needed

Verify output power from the outlet

Allow welder to cool at least 10 minutes with ma

chine ON (observe and maintain proper duty cy-

cle) FAULT/THERMAL OVERLOAD INDICATOR

LED should turn off after the machine has cooled.

Check for obstructions blocking air flow and en

sure that there are 12 inches Of clearance between

any obstacles and the vents on all sides of the ma

chine

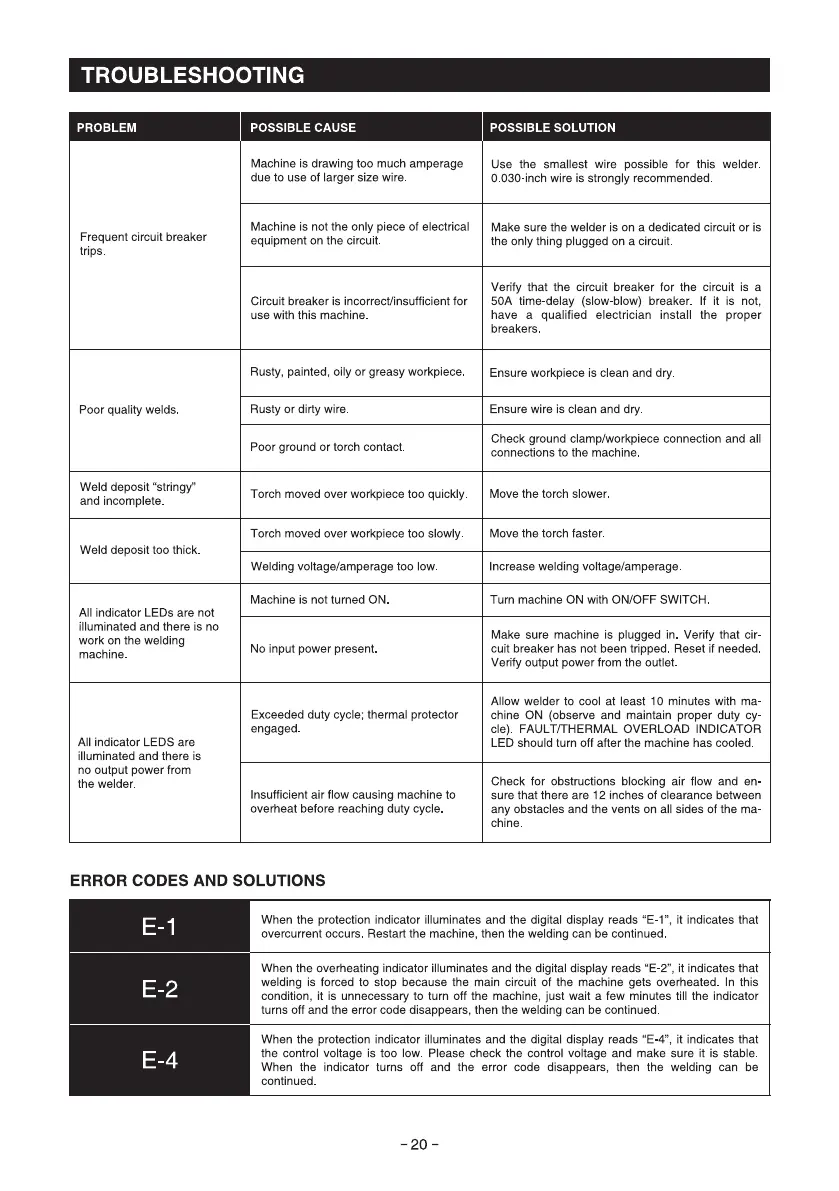

ERROR CODES AND SOLUTIONS

When the protection indicator illuminates and the digital display reads "E-1", it indicates that

overcurrent occurs. Restart the machine, then the welding can be continued

When the overheating indicator illuminates and the digital display reads "E-2", it indicates that

welding is forced to stop because the main circuit of the machine gets overheated In this

condition, it is unnecessary to turn off the machine, just wait a few minutes till the indicator

turns off and the error code disappears, then the welding can be continued

When the protection indicator illuminates and the digital display reads "E-4", it indicates that

the control voltage is too low Please check the control voltage and make sure it is stable

When the indicator turns off and the error code disappears, then the welding can be

continued

- 20 -

Loading...

Loading...