3. Cabling

3-33

TI 32P01J10-01EN

Signal Cable Termination

Solderless Lug

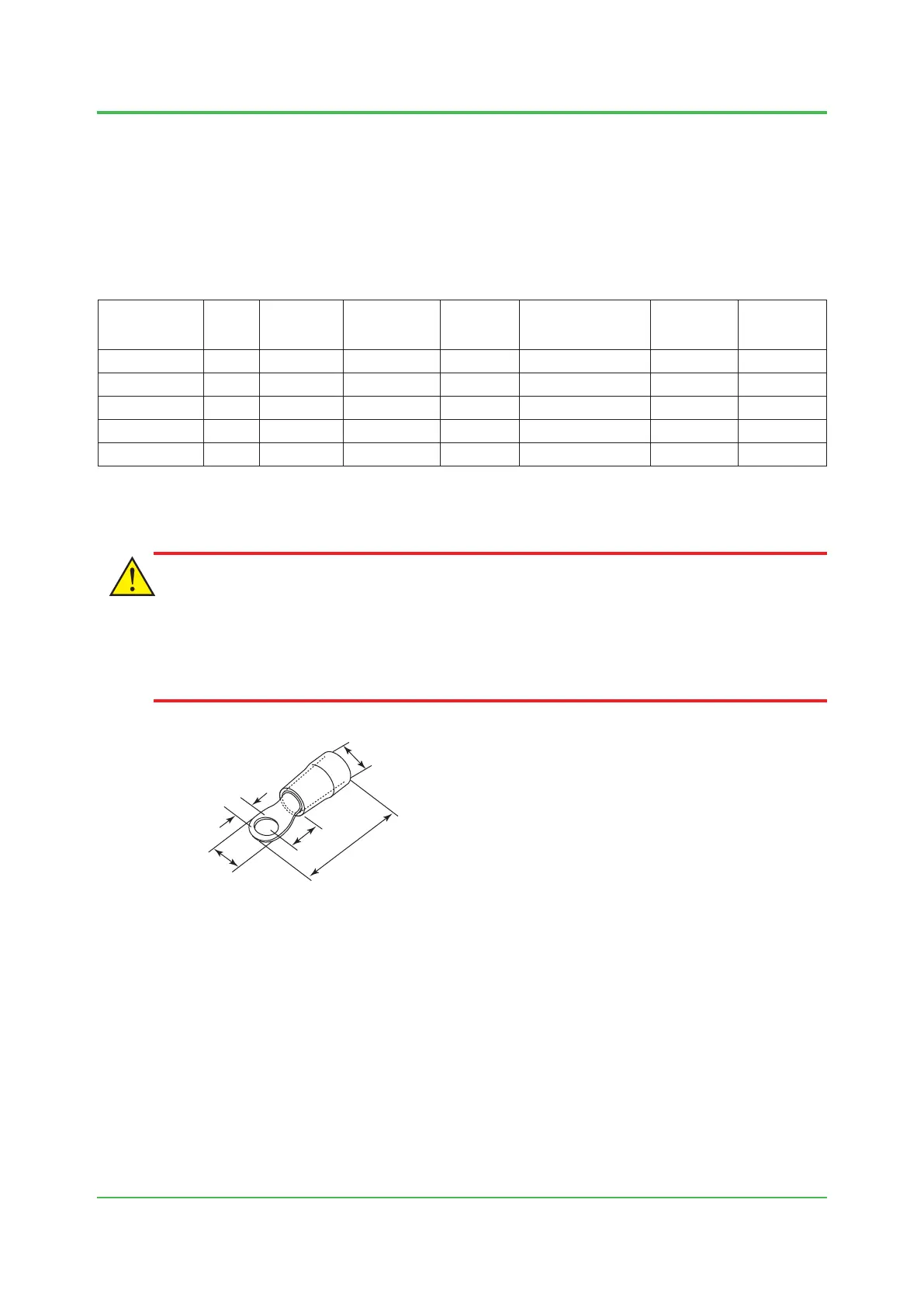

• Solderless lug specications

The specications for solderless lugs are determined by the nominal cross sectional area of

the power cable for which lugs are used, lug screws, terminal dimensions, and the like.

Table Solderless Lug Dimensions

Nominal cross

sectional area

(mm

2

)

Screw

used

(mm)

Hole

diameter

(mm)

Lug outside

diameter

(mm)

Lug

length

(mm)

Insulation covering

inside diameter

(mm)

Dimension

“C”

(mm)

Remarks

1.25 3.5 (*1) 3.7 or more 6.8 or less Approx. 21 3.6 or more 4.0 or more

2.0 3.5 (*1) 3.7 or more 6.8 or less Approx. 21 3.6 or more 4.0 or more

1.25 4 (*2) 4.3 or more 8.2 or less Approx. 21 3.6 or more 7.0 or more

2.0 4 (*2) 4.3 or more 8.7 or less Approx. 21 4.3 or more 7.1 or more

5.5 4 (*2) 4.3 or more 8.7 or less Approx. 25 5.8 or more 5.9 or more Only SED2D

*1: Recommended tightening torque is 0.8 N•m.

*2: Recommended tightening torque is 1.2 N•m.

CAUTION

• Always use solderless lugs with insulated covering.

• Always use solderless lugs and crimp-on tool manufactured by the same manufacturer.

• The crimp-on tool must be matched to the wire thickness.

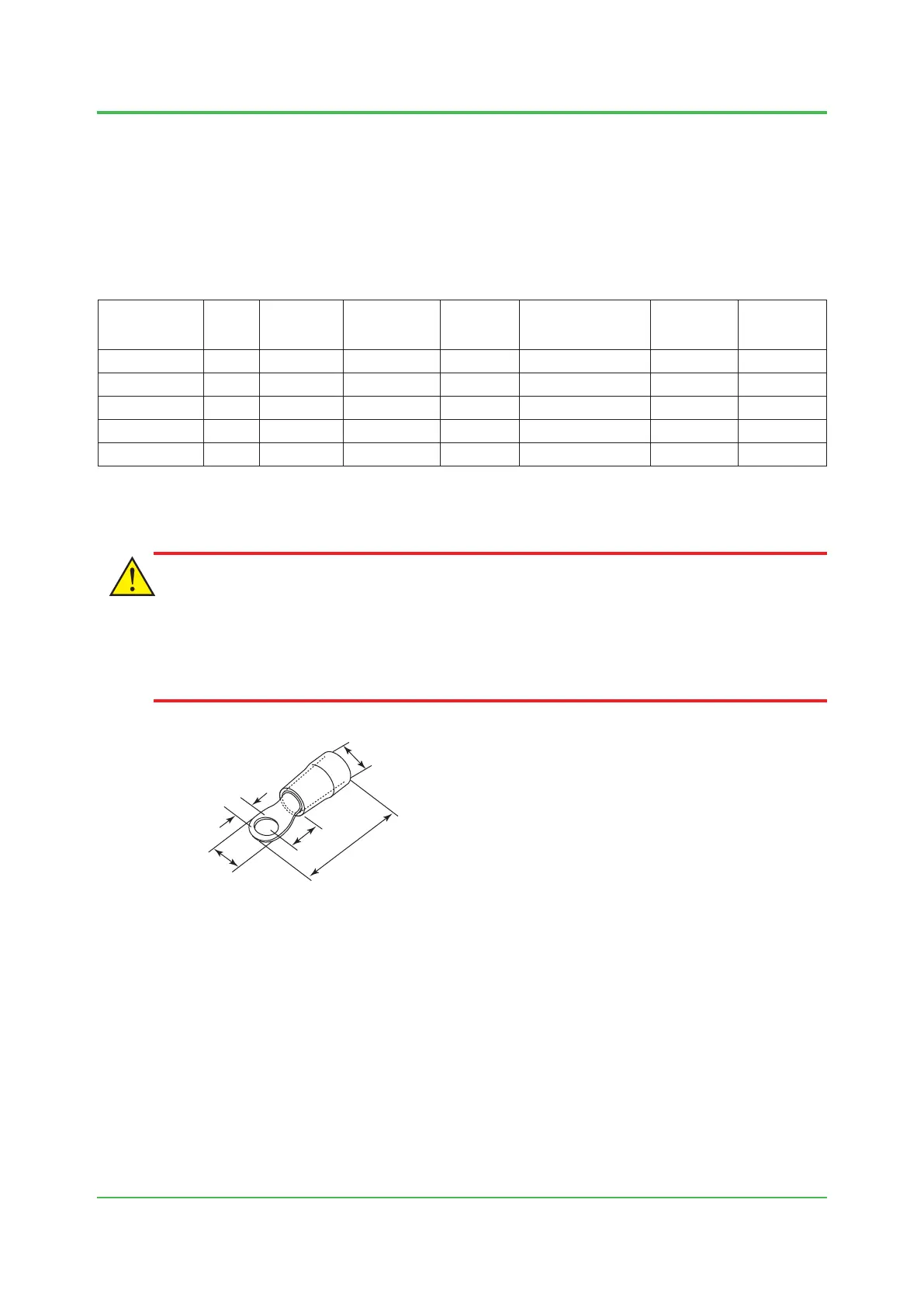

F030501.ai

Insulation covering

inside diameter

Lug outside

diameter

Lug length

C

Figure Solderless Lug

Oct. 25, 2016-00

Loading...

Loading...