3-4

All Rights Reserved. Copyright © 2004, Yokogawa Electric Corporation

<Toc> <Ind>

TI 11M12A01-01E

3. System Configurations

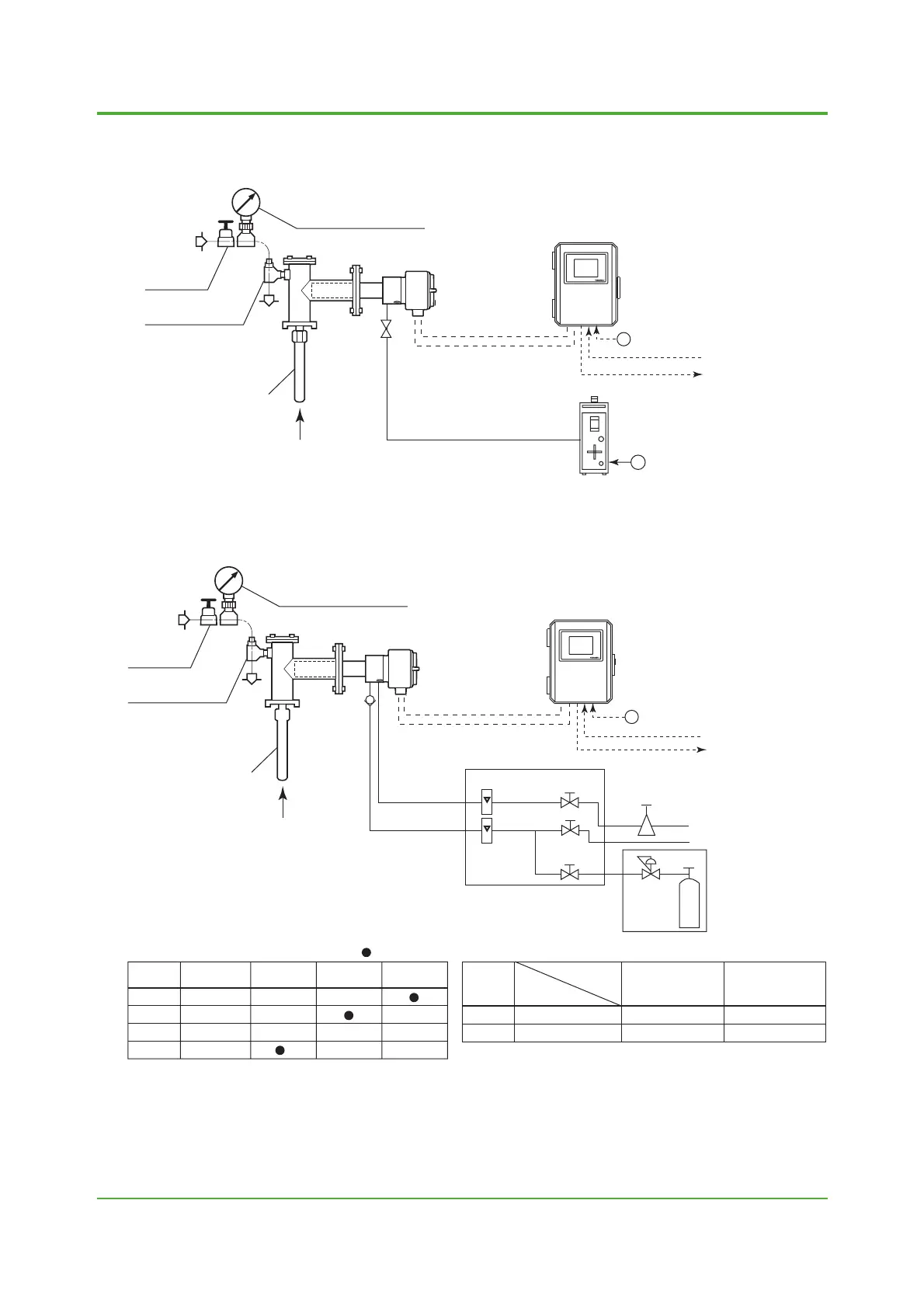

(4) Type: H1 (simple measurement system)

EXA

ZR402G

⬃

⬃

F0304.EPS

<2> ZR402G Converter

<1> High-temperature detector ZR22G-015

Calibration gas

<3> ZO21S Standard gas unit

100 to

240 V AC

Contact input

Analog output,

contact output

(Digital output HART)

Signal

(6-core shield cable)

Air supply

(1.5kgf/cm

2

)

Needle

valve

*2

*3

Ejector ASSY

Pressure gauge ASSY

Heater (2-core)

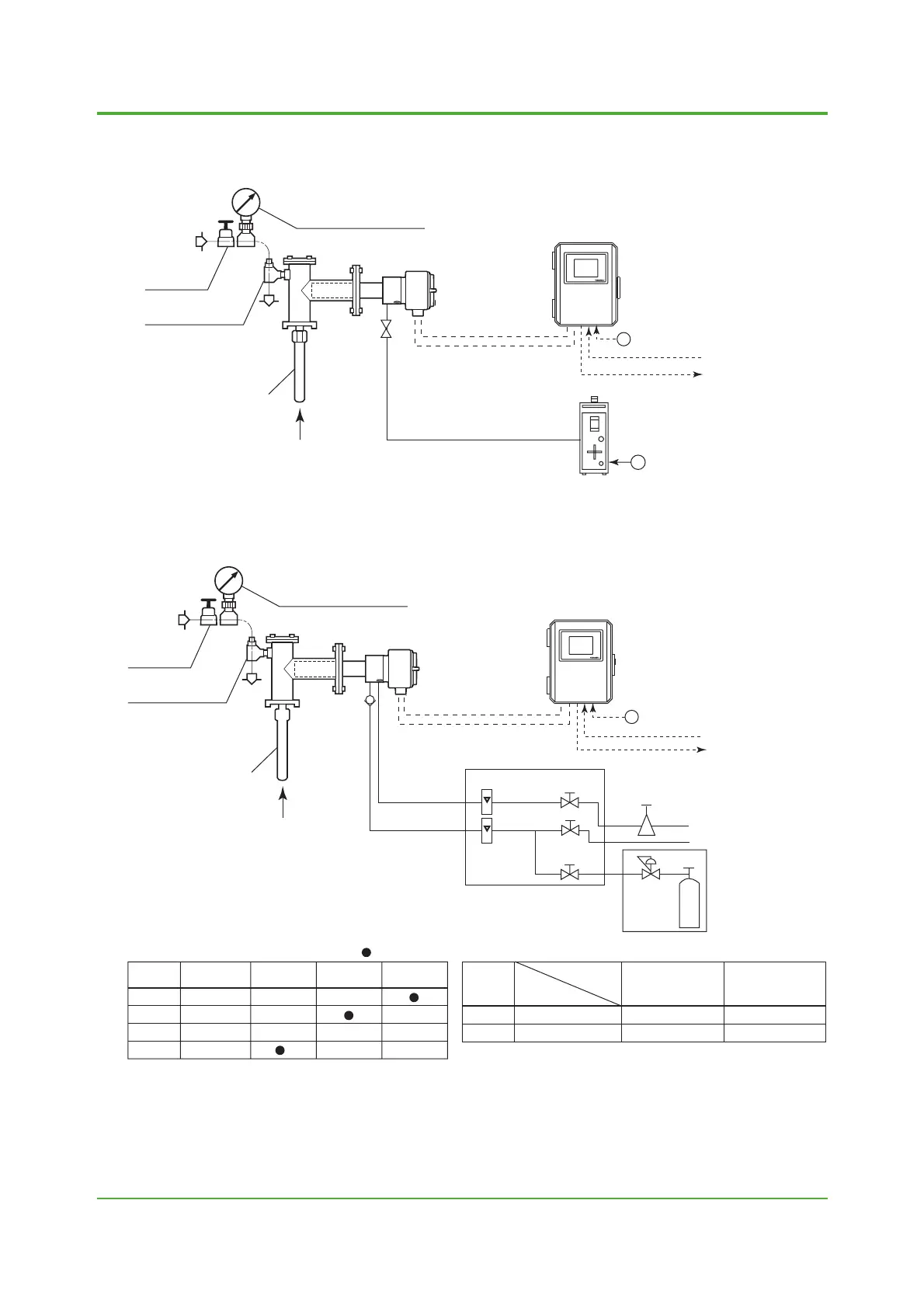

(5) Type: H2 (no auto calibration, no safety purge)

F0305.EPS

Check

Vertical downward

mounting

Horizontal

mounting

Mounting

orientation

Maximum

temperature (°C)

800

1400

SUS310S

—

SUS310S

SiC

Note 3: Selection of high temperature probe material

: Necessary

Check

Needle

valve

*1

Ejector

ASSY

*2

Ejector

ASSY

*3

Pressure

kPa

–0.5

–0.5 to 0.05

0.05 to 0.5

0.5 to 5

*1: K9473XH/K9473XJ

*2: E7046EC/E7046EN

*3: consult with YOKOGAWA

Note 2: Selection of Needle valve or Ejector

⬃

EXA

ZR402G

<2> ZR402G Converter

<3> ZA8F flow setting unit

100 to

240 V AC

Air Set

Instrument air

Calibration gas

Regulator

Reference

gas

Flowmeter

Needle

valve

Zero gas

cylinder

Span gas

Contact input

Analog output,

contact output

(Digital output HART)

Signal

(6-core shield cable)

Heater (2-core)

<1> High-temperature detector ZR22G-015

Air supply

(1.5kgf/cm

2

)

Needle

valve

*2

*3

Ejector ASSY

Pressure gauge ASSY

May 31,2004-00

Loading...

Loading...