3-6

All Rights Reserved. Copyright © 2004, Yokogawa Electric Corporation

<Toc> <Ind>

TI 11M12A01-01E

3. System Configurations

3.3 Examples of System Component Selection Based on Sample

Gas Conditions

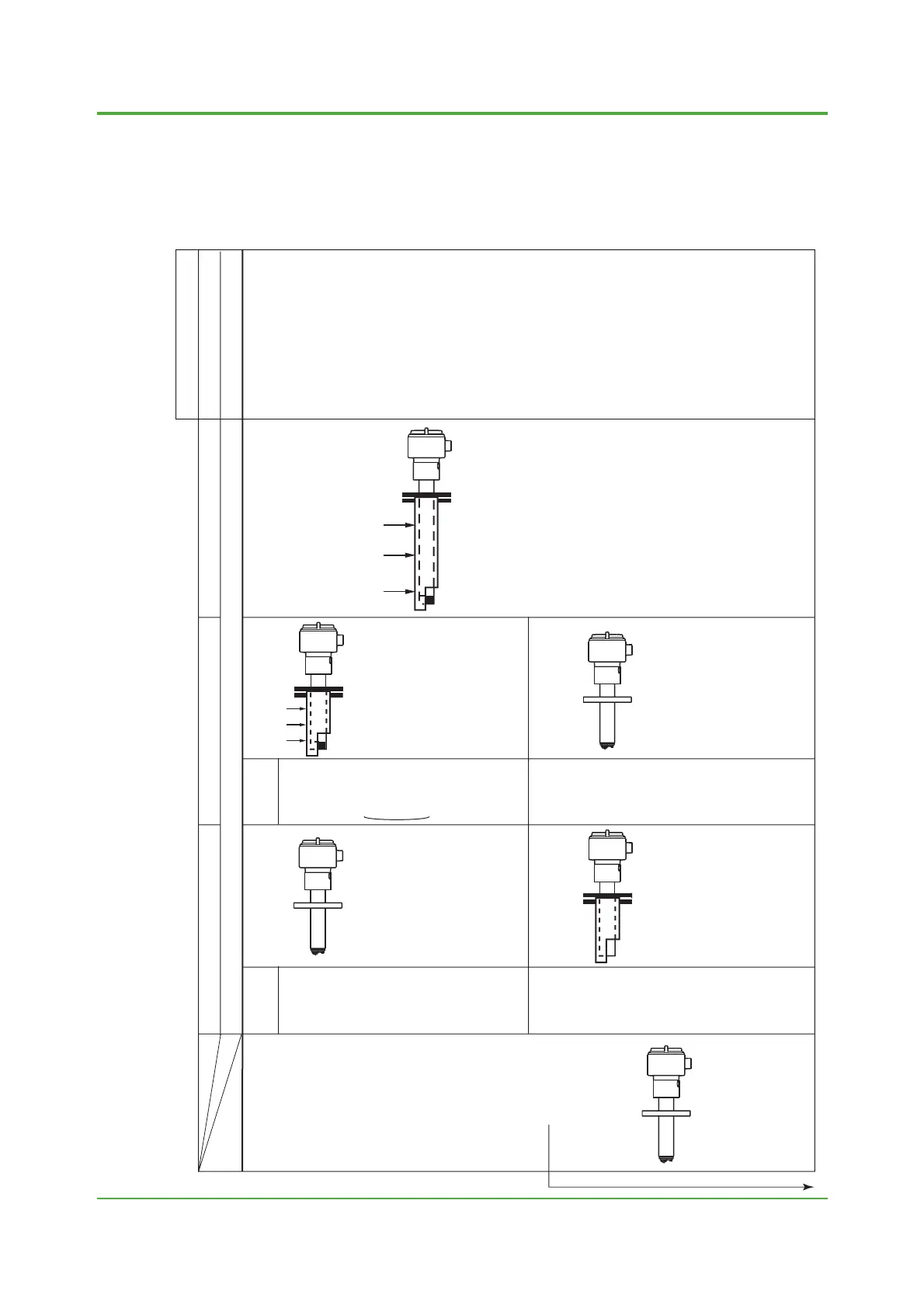

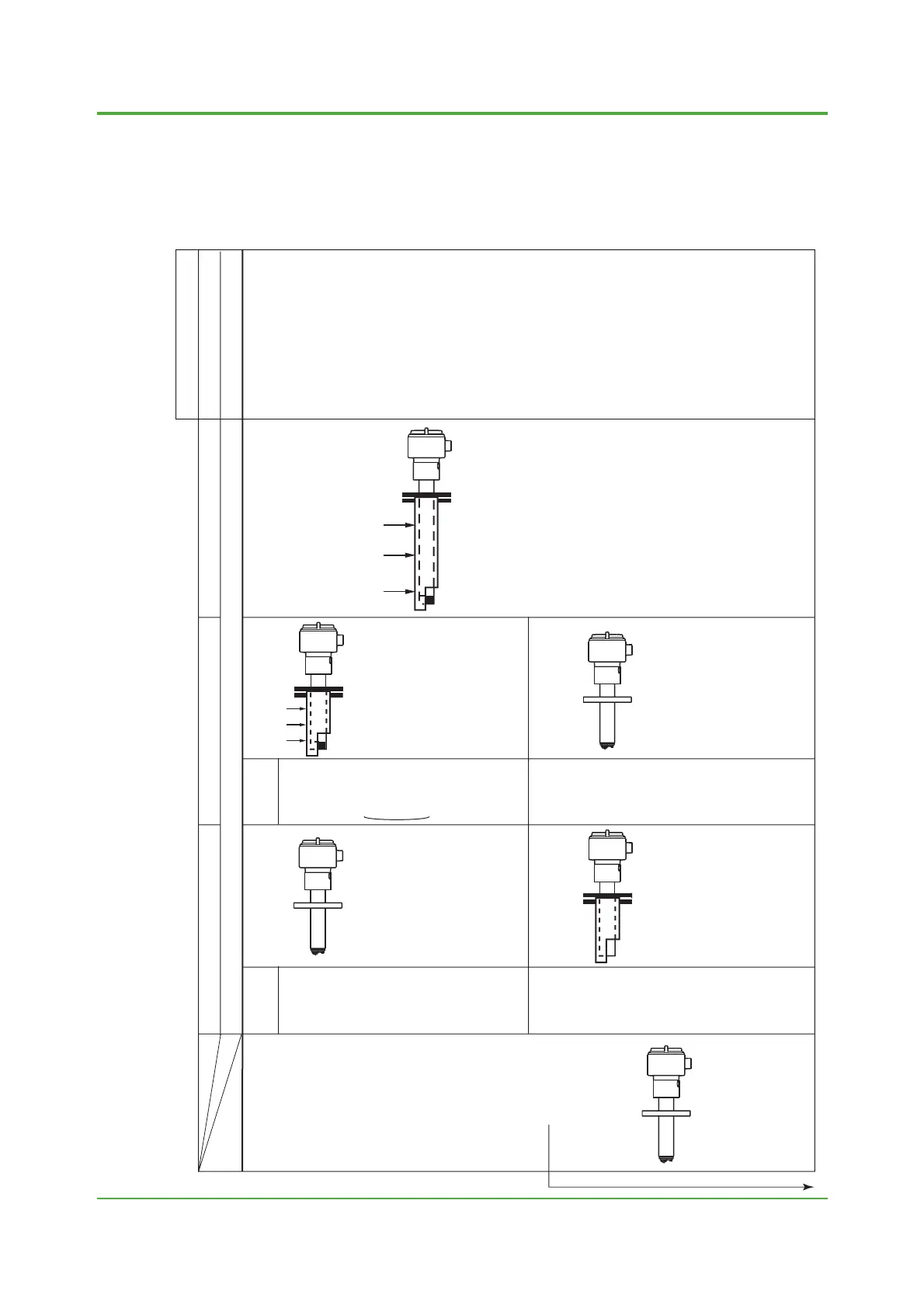

1) Detector and its accessories

F0307.EPS

Low (0.5 g/Nm

3

or less)

Dust level

Pre

s

s

ure

Temperature

(°C)

High (10 g/Nm

3

or less) Very high (200 g/Nm

3

or less)

Remarks

–5 to +250 kPa (Note 1)

Insertion

length

Abrasive

2.5 m~3 m No

[D1]

[D2]

[D4]

[D3]

General-purpose

detector with

probe protector

(Note 2)

ZR22G

with ZO21R-L

General-purpose

detector with dust

guard protector

or with sic filter

General-purpose detector

with protector filter

General-purpose detector

with probe protector or

with sic filter

(Note 2)

ZR22G

with ZO21R-L

or with K9471UA

ZR22G

with K9471UC

or with K9471UA

General-purpose

detector

General-purpose

detector with

probe supporter

ZR22G

with ZO21R-L

or with K9471UA

Ye s

Coal,

pulverized

coal boiler,

etc.

General-purpose

detector

Less than

2.5 m

ZR22G

0

to

700

(Note 1)

When the pressure in the

furnace exceeds 3 kPa, it is

recommended that you

compensate the pressure.

When the pressure in the

furnace exceeds 5 kPa, you

must perform pressure

compensation. For 0.15m

probe, 0.5 to 5 kPa. No

pressure fluctuation in the

furnace should be allowed.

(Note 2)

Downward oriented mounting

preferred.

May 31,2004-00

Loading...

Loading...