JOHNSON CONTROLS

109

SECTION 3 - OPTIVIEW™ CONTROL CENTER FUNCTIONS AND NAVIGATION

FORM 160.84-OM1

ISSUE DATE: 9/21/2017

3

MESSAGE DESCRIPTION

VSD – 105% MOTOR

CURRENT OVERLOAD

The 105% motor current overload value is based on the highest output current compared to the

programmed Motor Current value displayed on the Control panel. The 105% motor current over-

load value is 1.05 times the programmed Motor Current value displayed on the Control panel.

The motor current overload value must be greater than the shutdown value for 40 continuous

seconds for this shutdown to occur.

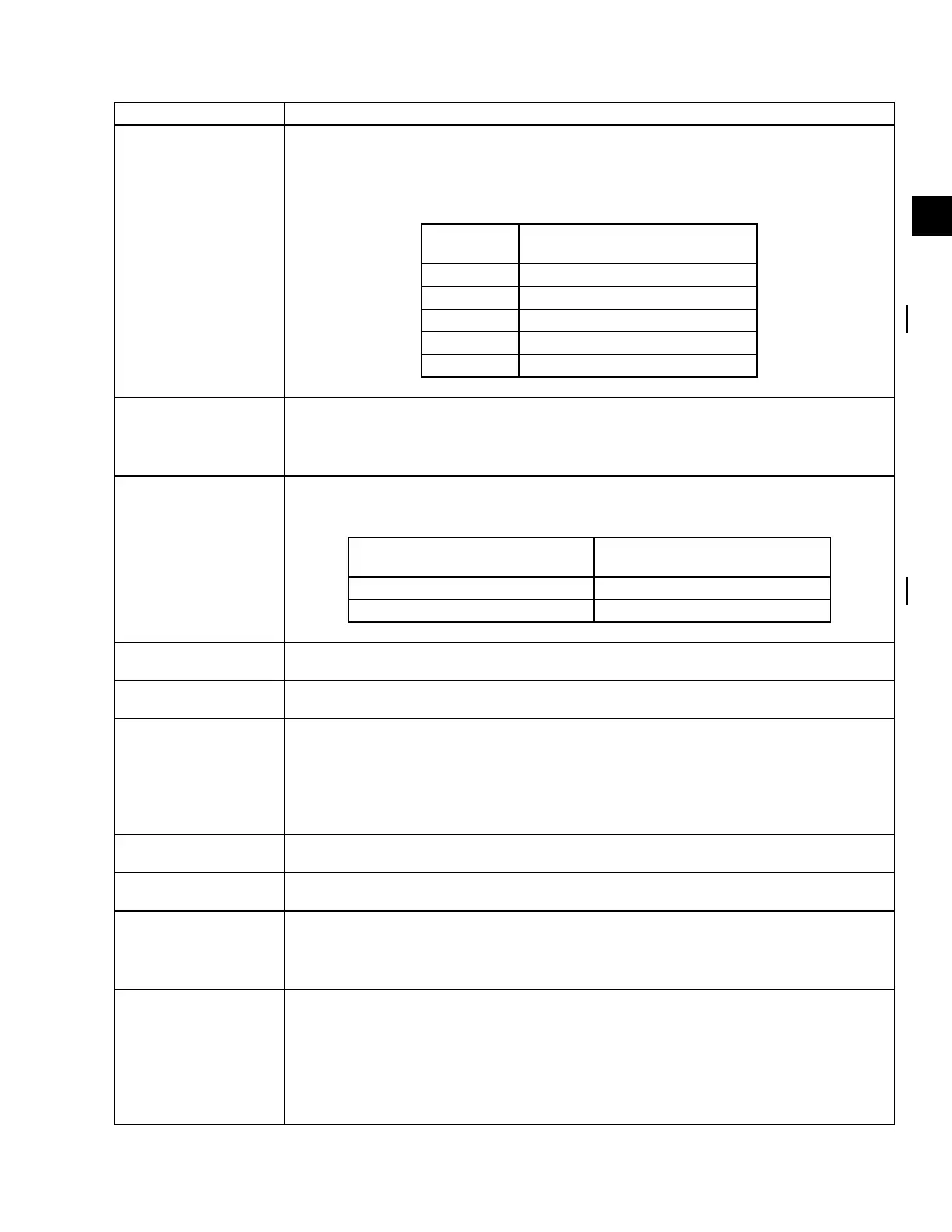

DRIVE

MODEL

MAXIMUM MOTOR CURRENT

OVERLOAD SHUTDOWN VALUE

0490, 0490A 490 Amps

0612A 612 Amps

0730A 730 Amps

0774 774 Amps

1278A 1278 Amps

When the condition clears, the chiller can be started after the CLEAR FAULTS key is pressed.

VSD – MOTOR

CURRENT THD FAULT

This shutdown provides protection to the compressor motor. High levels of current total harmon-

ic distortion (THD) can cause the motor to overheat. Verify that all wiring is properly connected

between the inverter and the output harmonic lter. When the condition clears, the chiller can be

started after the CLEAR FAULTS key is pressed.

VSD – PHASE A INPUT

DCCT

The input current in each phase to the VSD is measured during the precharge time. If the input

current does not exceed the shutdown value for the given model of drive listed below, then this

shutdown is generated.

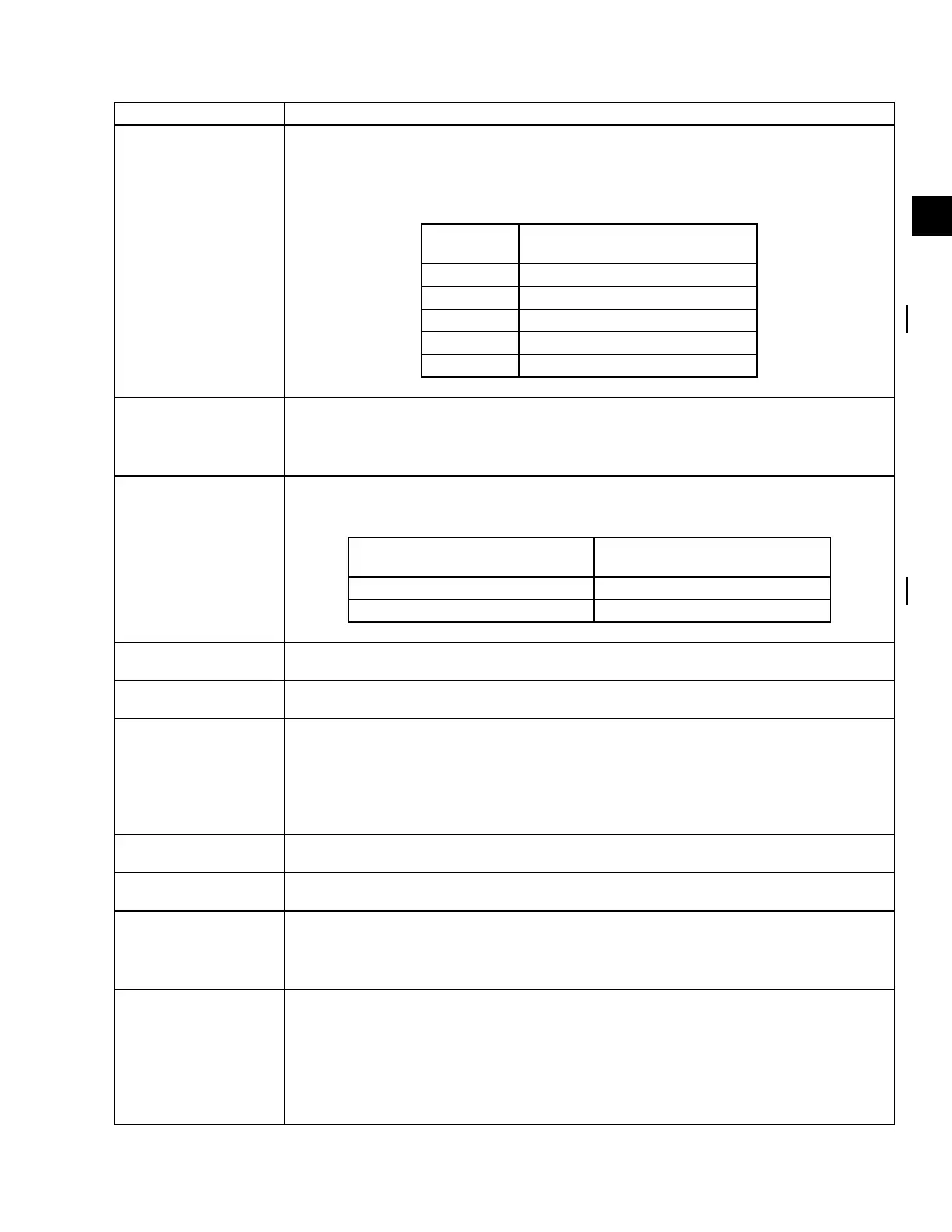

DRIVE

MODEL

MINIMUM INPUT CURRENT

SHUTDOWN VALUE

0490A, 0490, 0612A, 0730A, 1278A 5.0 amps

0774 15.0 amps

When the condition clears, the chiller can be started after the CLEAR FAULTS key is pressed.

VSD – PHASE B INPUT

DCCT

See “VSD –PHASE A INPUT DCCT” message preceding.

VSD – PHASE C INPUT

DCCT

See “VSD – PHASE A INPUT DCCT” message preceding.

VSD – PHASE A MO-

TOR DCCT

The motor current in each phase of the VSD is measured at the beginning of the run command.

The motor current at this time should measure very low. This low value will be used as the zero

current value for the rest of this run time. The motor current is then monitored for the next 1.5

seconds to ensure that a minimum amount of current is owing to the motor. If at the end of the

1.5 second time a minimum of 25 amps peak is not detected, then this shutdown is generated.

When the condition clears, the chiller can be started after the CLEAR FAULTS key is pressed.

VSD – PHASE B MO-

TOR DCCT

See “VSD –PHASE A MOTOR DCCT” message preceding.

VSD – PHASE C MO-

TOR DCCT

See “VSD – PHASE A MOTOR DCCT” message preceding.

VSD – PHASE LOCKED

LOOP

The VSD must be able to determine the input voltage frequency from the input voltage measure-

ment. If the input voltage frequency is not stable enough for the VSD to make this determination,

then this shutdown is generated. When this condition clears, the chiller can be started after the

CLEAR FAULTS key is pressed.

VSD – PRECHARGE

LOCKOUT

If the unit fails to complete pre-charge (due to VSD – PRECHARGE – LOW DC BUS VOLTAGE

or VSD – PRECHARGE – HIGH DC BUS VOLTAGE), the VSD shall time 10 seconds before

clearing the fault and allowing another pre-charge to start. The unit’s fan(s) and water pump(s)

shall remain energized during this time. The VSD shall allow up to three consecutive pre-charge-

related faults to occur. After the third consecutive pre-charge-related fault, this shutdown is

generated. When the condition clears, the chiller can be started after the CLEAR FAULTS key is

pressed.

TABLE 12 - SAFETY SHUTDOWN MESSAGES (CONT'D)

Loading...

Loading...