FORM 155.19-EG3 (1011)

19JOHNSON CONTROLS

LD01008

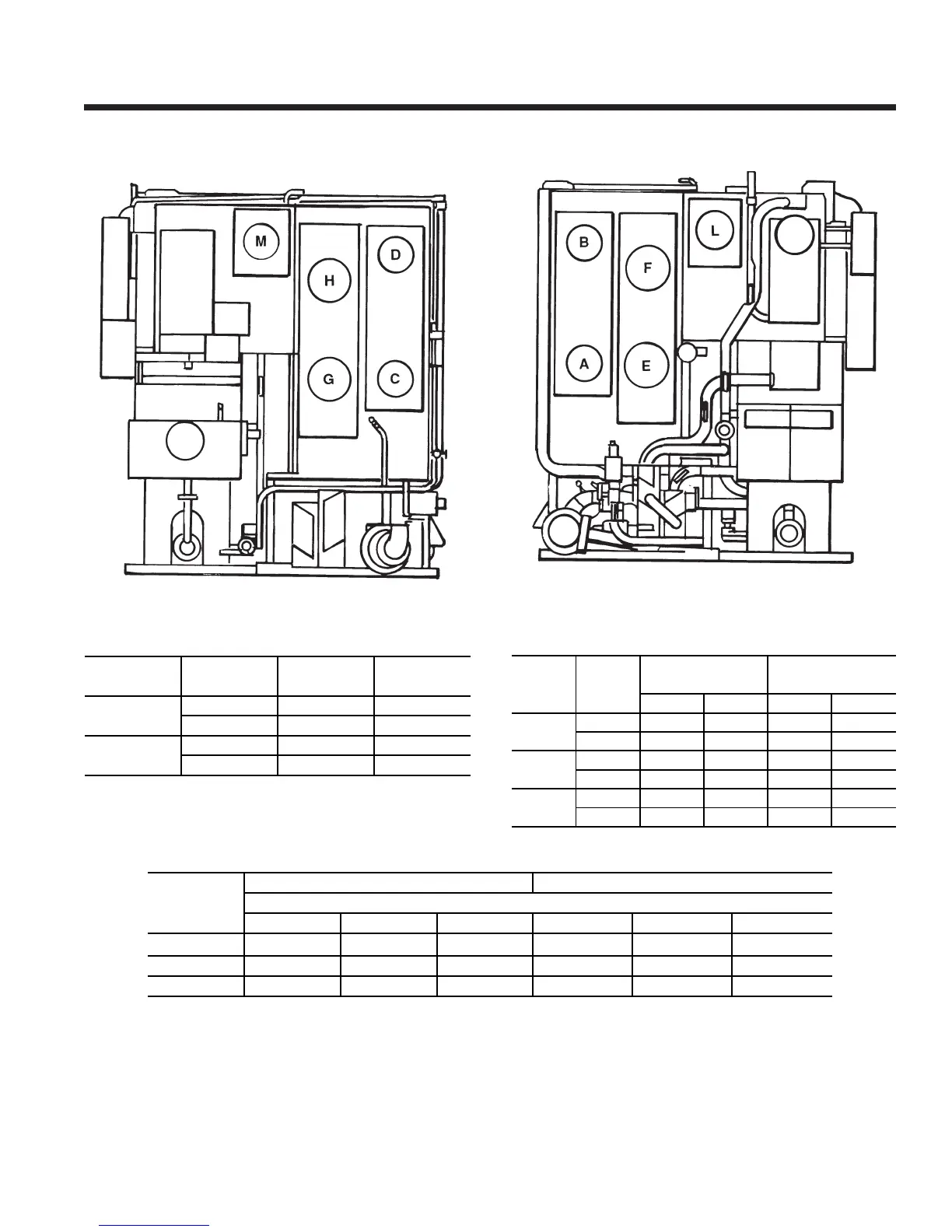

STEAM INLET OPPOSITE END

Nozzle Arrangement 16SL and Larger

NOZZLE SIZES

*Number of passes refers to the number of absorber passes only. The condenser is always one pass with nozzle sizes that match the absorber.

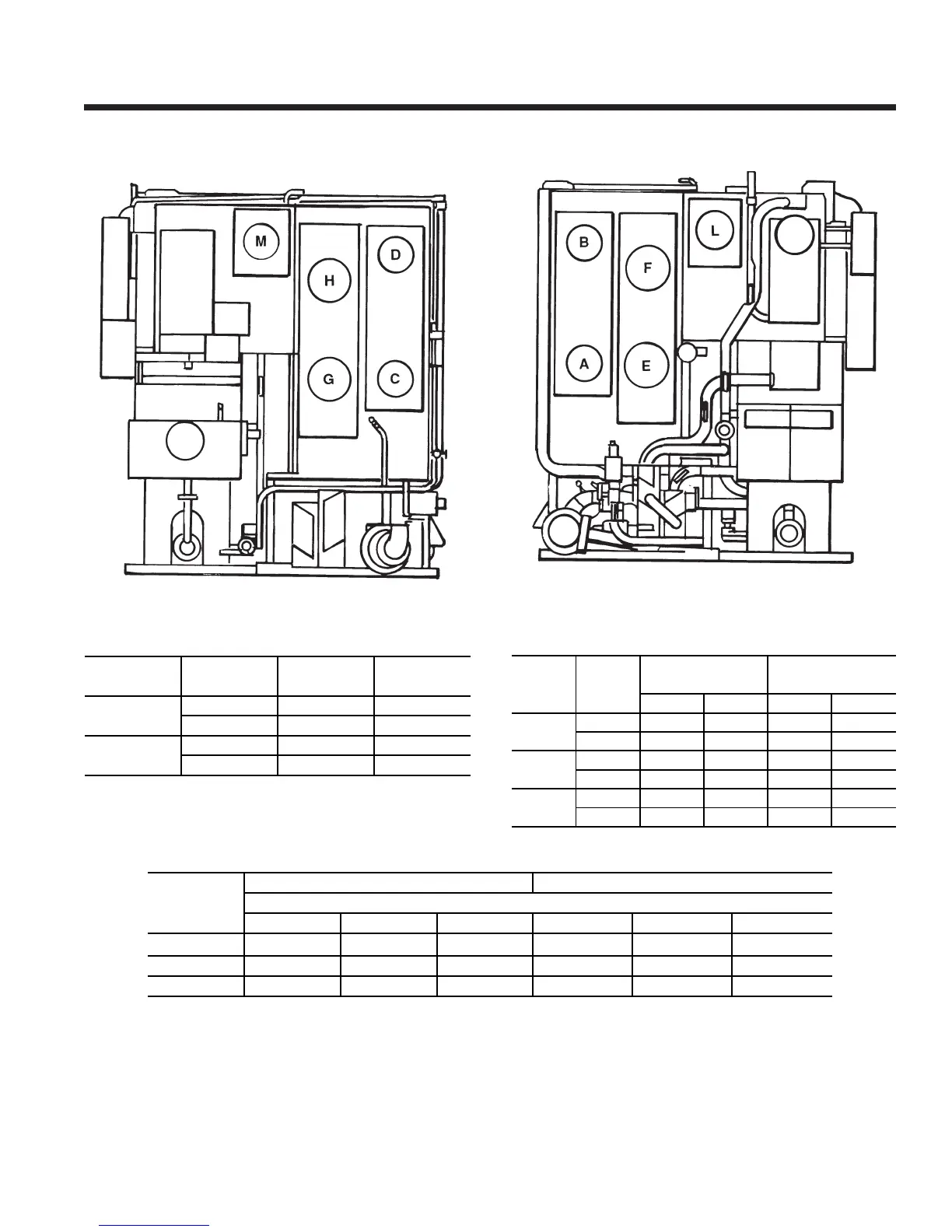

EVAPORATOR NOZZLE ARRANGEMENTS TOWER WATER NOZZLE ARRANGEMENTS

NOTES:

1. Choose desired nozzle arrangement – water boxes are not interchangeable.

2. Standard water nozzles are furnished as welding stub-outs with ANSI/AWWA C-606 grooves, allowing the option of welding, anges, or the use

of ANSI/AWWA C-606 couplings. Factory installed, class 150 (ANSI B16.5, round slip-on, forged carbon steel with 1/16” inch raised face), water

anged nozzles are optional. Companion anges, nuts, bolts, and gaskets are not furnished.

3. Connected piping should allow for removal of compact water box for tube access and cleaning.

4. Tower water must enter the absorber rst for proper performance.

NO. OF PASSES (IN) (OUT)

3

E1 A D

E4 C B

2,4

E5 A B

E7 C D

NOZZLE

ARRANGEMENT

ABSORB. COND.

IN OUT IN OUT

1

C1 F H M L

C2 H F L M

2

C3 E F L M

C4 G H M L

3

C1 E H M L

C2 G F L M

NO. OF ABS.

PASSES

NOZZLE

ARRANGE-

MENT

UNIT

EVAPORATOR ABS./COND.

NUMBER OF PASSES

2 3 4 1* 2* 3*

16SL & 17S 8” 6” 6” 12” 10” 8”

18S 8” 6” 6” 12” 10” 8”

19S 8” 6” 6” 12” 10” 8”

Loading...

Loading...