6 JOHNSON CONTROLS

FORM 155.19-EG3 (1011)

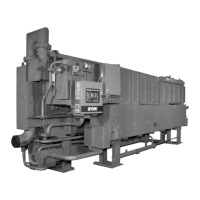

MicroComputer Control Center

The MicroComputer Control Center is designed for the

very best chiller protection and overall system efciency.

As standard equipment on all Millennium YPC Two-Stage

Absorption chillers, the Control Center is a major develop-

ment in absorption chiller technology, providing the most

precise and reliable control available in the industry.

INFORMATION DISPLAY

Vital chiller operating information can be shown on the 40

character alphanumeric display. All information is in the

English language with numeric data provided in English

or metric units. Information provided standard on all units

includes:

• Chilled water temperatures, entering and leaving

• Tower water temperatures, entering and leaving

• First-stage generator pressure and temperature

• Refrigerant temperature

• Solution temperature

• Operating hours

• Number of starts

• Number of purge cycles (last 7 days and lifetime total)

• Steam valve position (in %)

• Indication of each pump’s operation

In addition, all operating and setpoint information can

be transmitted to an optional remote printer through the

RS232 port to obtain data logs:

• At any time by pressing the PRINT button

• At set time intervals by programming the panel

• After a safety shutdown to list the cause of the shut-

down and the operational parameters just prior to

shutdown

• For a complete history printout of the last four shut-

downs and operational parameters just prior to shut-

down.

CAPACITY CONTROL

When automatic capacity control is desired, the Micro-

Computer Control Center automatically varies the steam

ow rate to maintain the programmed leaving chilled water

set point for cooling loads ranging from 20% to 100% of

design.

• Digital keypad entry of setpoint to 0.1°F (0.1°C)

• Verify actual vs. setpoint temperature via alphanu meric

display

• Remote reset of setpoint (up to 20°F (or 11.1°C) range)

with a 1 to 11 second PWM signal (optional 4-20mA,

0-10VDC or contact closure).

When automatic control is not desired, the input steam

ow rate is also manually adjustable for the MicroComput-

er Control Center panel to any setting between minimum

and maximum, provided steam input is not inhibited by a

specic operating condition (e.g. safety).

STEAM LIMITING CONTROLS

• Manual limiting available from 20% to 100% of capac-

ity.

• Programmable pull down demand limiting to auto-mat-

ically limit steam source loading at start-up.

• Remote limiting of steam input form 30% to 100% with

a 1 to 11 second PWM signal.

SYSTEM CYCLING CONTROLS

• Programmable seven day time clock for automatic

start/stop of chiller and chilled condenser water pumps.

• Separate schedule input strictly for holidays

• Remote cycling contacts available for other eld sup-

plied signals

• Multi-unit cycling contact input terminals for eld sup-

plied signals

Loading...

Loading...