Edition 2 Chapter 1 Page 1-28

Feb/2013 Maintenance and Service

1.15 GEAR OIL

A. Always use the correct gear oil (type and viscosity) in the crane.

B. When the crane comes out of the factory, the gear oil level is full. You must use

the data from Table 1-4 when you choose the type of oil for the crane.

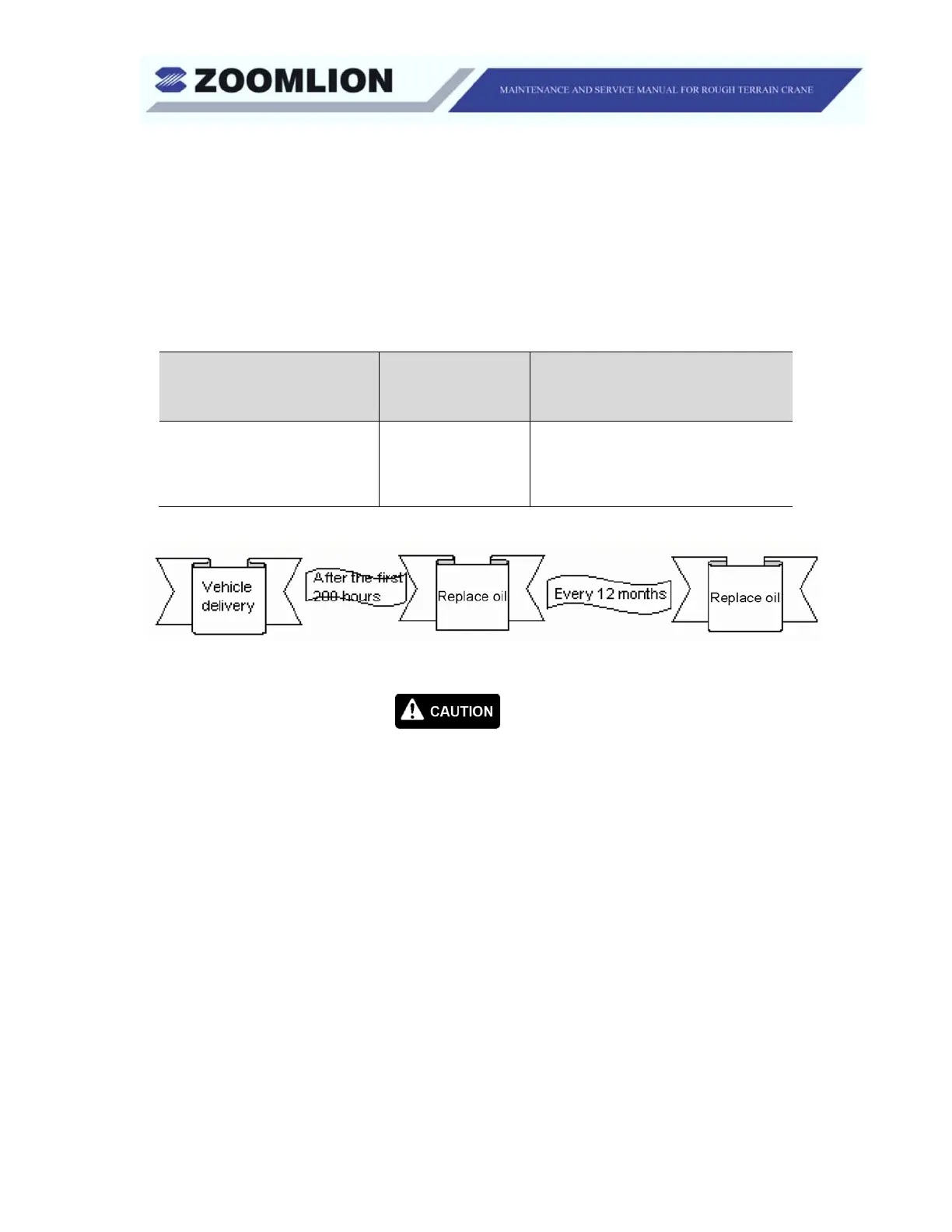

Table 1-4 Gear Oil Performance

Kinematic viscosity at

212° F (100 °C)

mm²/s

Minimum flash

point (split)

° F (° C)

Ingredients

56.3 (13.5) ~<24.0

329 (165)

Organic acid fat, phosphoric acid

fat, silicic acid fat, fluorin oil, silicon

oil, polyphenylene oxide +

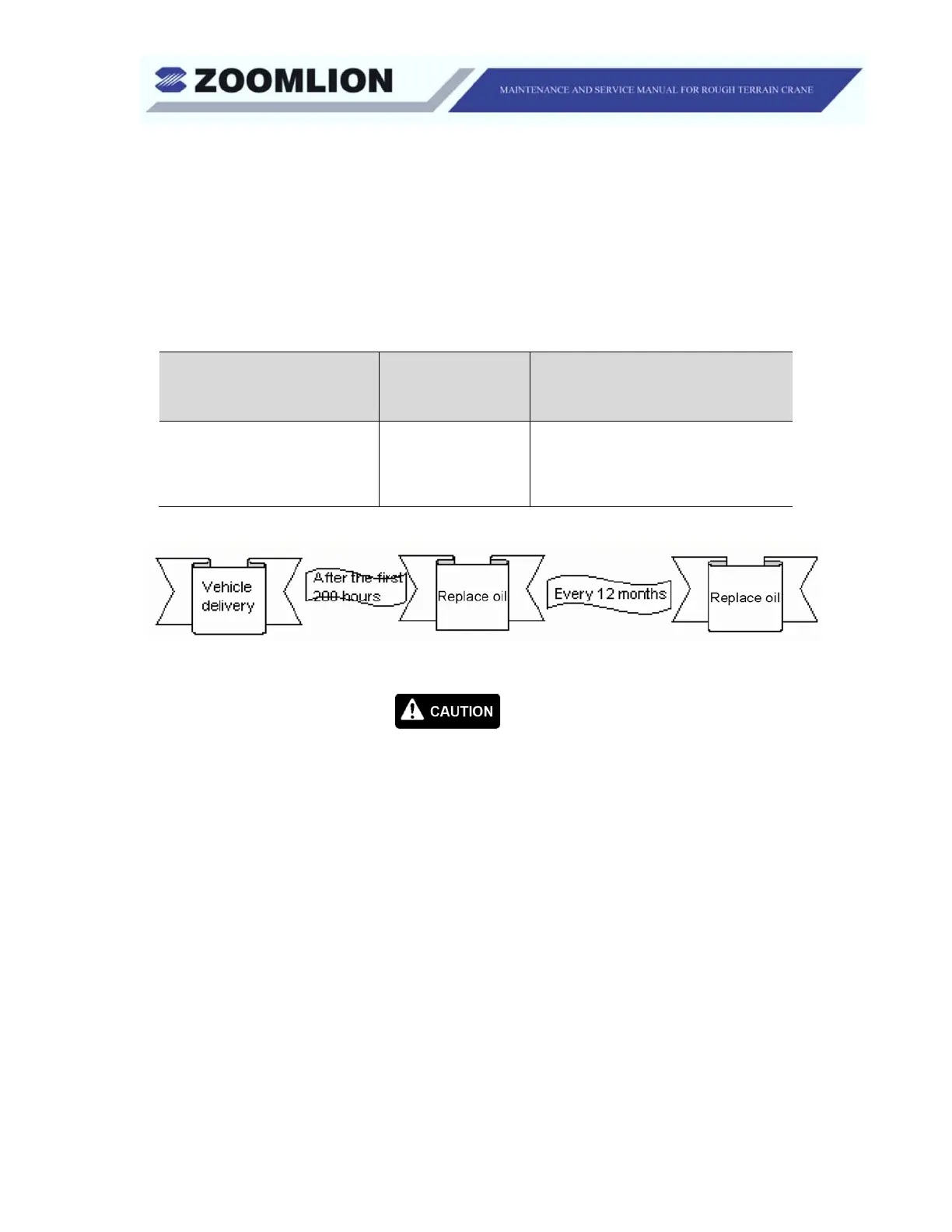

Figure 1-18 Changing Intervals

When there is contamination in the gear oil, change the oil immediately.

Monitor the oil level regularly and add oil if it is below the low mark.

You cannot mix oil of different brands (specifications) or types.

Always use the correct oil based on the temperature the crane operates in.

If you use the incorrect oil (type or viscosity) in the reducer mechanism,

you can damage it.

Loading...

Loading...