Edition 2 Chapter 2 Page 2-7

Feb/2013 Troubleshooting

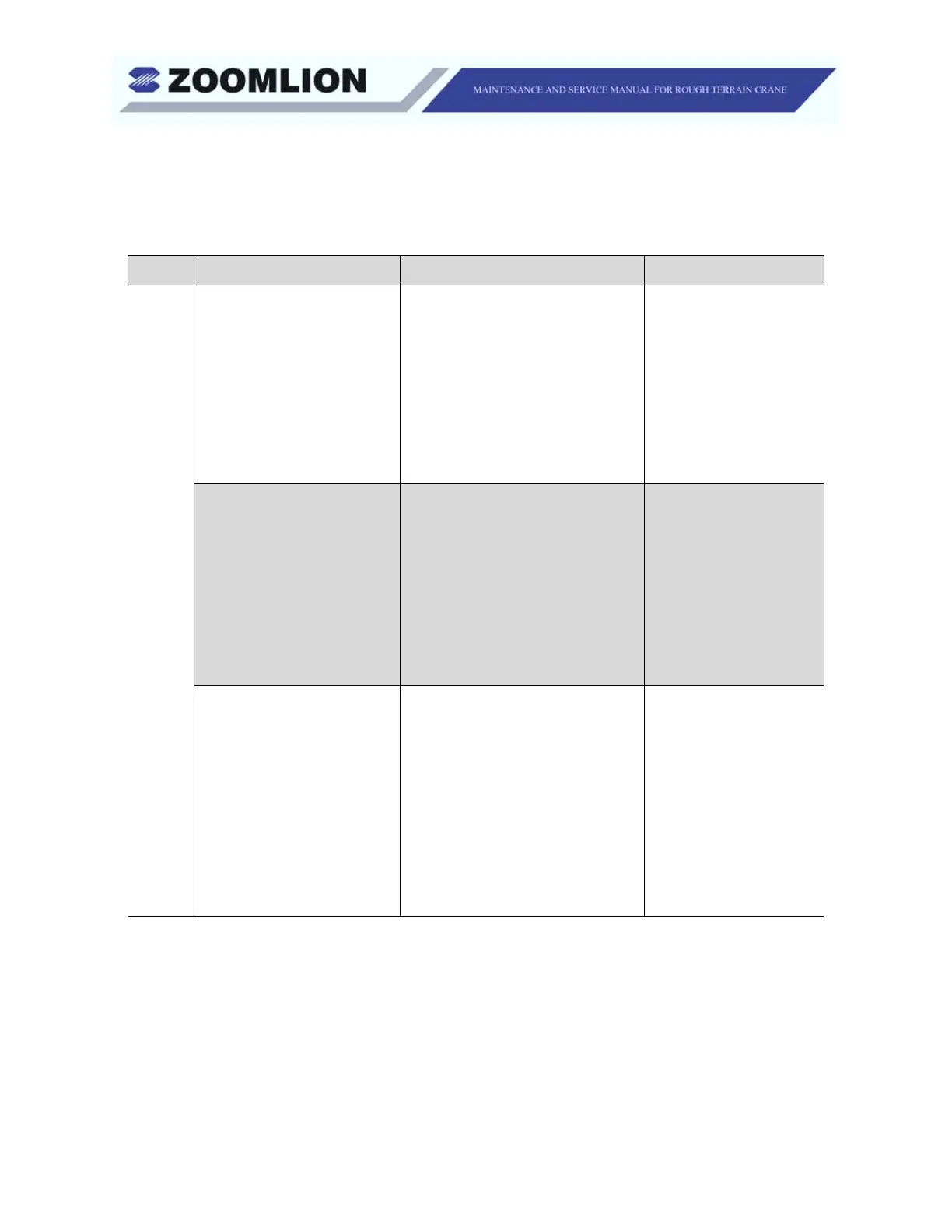

2.6 HOIST MECHANISM

Table 2-6

Part Problem Cause Remedy

Electrical System

Hook cannot go up

a) Relief valve pressure for

the main valve is set too

low.

b) Hydraulic motor defective

c) Main valve defective

d) Electrical system defective

e) Winch reducer does not

turn

Set the pressure to 27

MPa.

Replace

Repair

Repair

Examine the pilot

valve and the brake

valve

Hook cannot go down

a) Relief valve pressure for

the main valve is set too

low

b) Hydraulic motor defective

c) Main valve defective

d) Electrical system defective

e) Balance valve defective

f) Winch reducer does not

turn

Adjust or repair

Repair

Repair

Repair

Replace

Repair

Brake defective

a) Brake cannot engage or

disengage (Pilot oil source

pressure for the main valve

is set too low).

b) Brake pad is seriously

worn.

c) Air in the brake system

d) Hydraulic motor defective

(pump volume is too low,

not enough oil flow to do

multiple tasks).

Set the pressure to 3

MPa

Replace

Bleed the system

Repair or replace

Loading...

Loading...