Edition 2 Chapter 1 Page 1-31

Feb/2013 Maintenance and Service

1.17 LUBRICATING POINTS

A. You can use Table 1-6 and Figure 1-22.

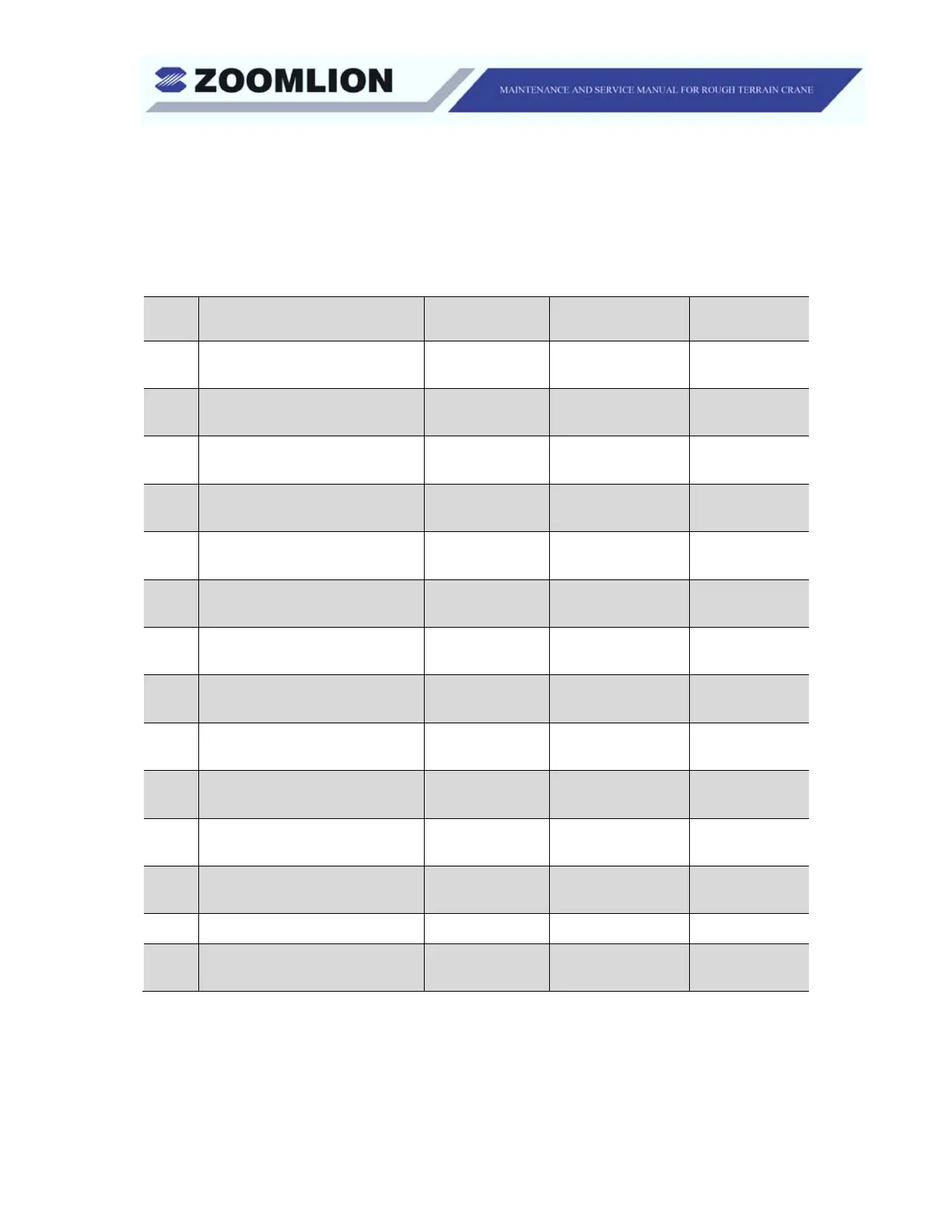

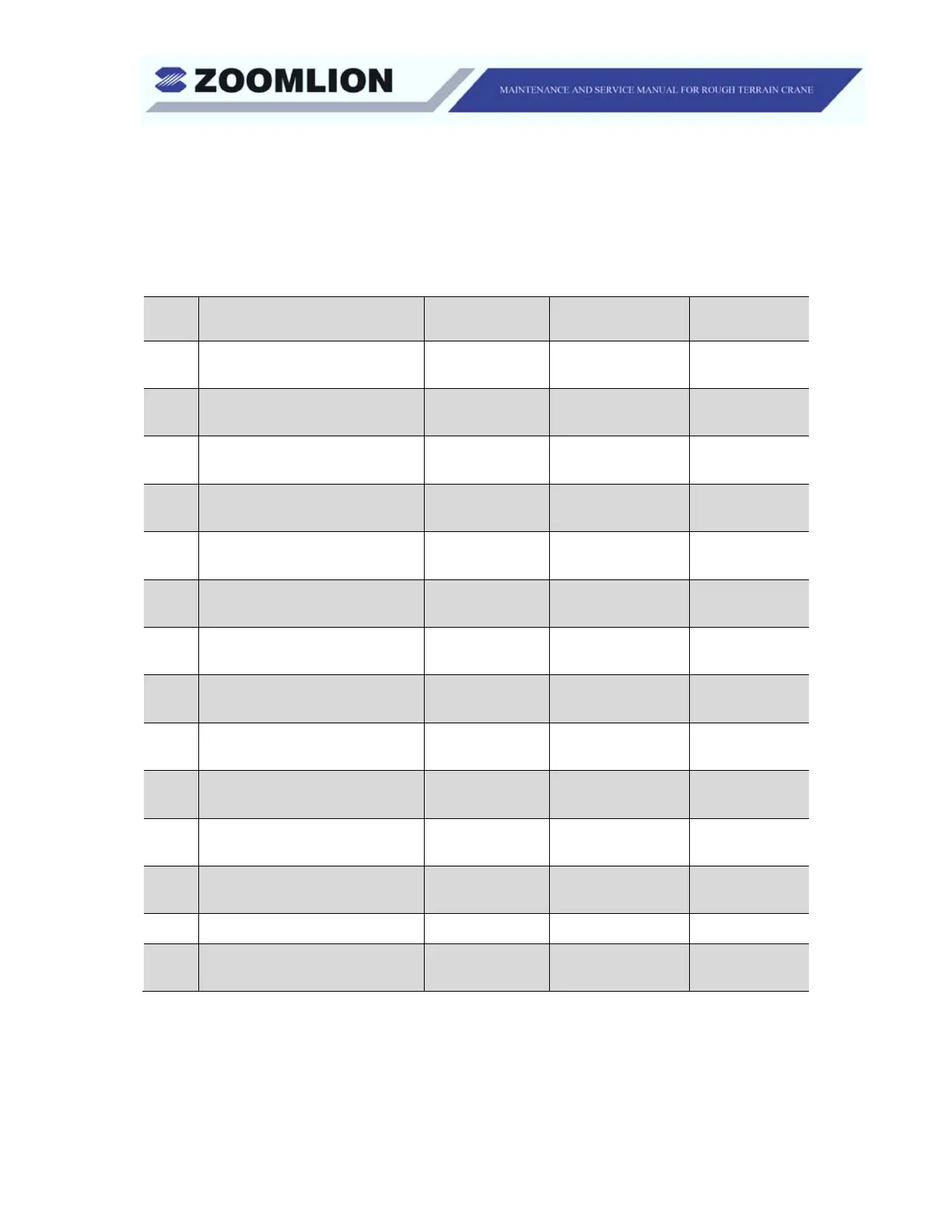

Table 1-6 Lubrication Intervals and Points

No. Description Intervals Method

1

Upper pulley block (shaft) on

main boom

10 Days Grease ZL-2

2 Slider pads of main boom 10 Days

Grease or inject

with grease pump

ZL-2

3

Lower pulley block (shaft) on

main boom

10 Days

Inject with grease

pump

ZL-2

4

Sliding surfaces of the main

boom

10 Days Grease ZL-2

5

Upper articulated-point shaft

of derricking cylinder

Monthly

Inject with grease

pump

ZL-2

6

Pulley block (shaft) on main /

auxiliary hook

10 Days

Inject with grease

pump

ZG-3

7 Drive lines of oil pump Daily

Inject with grease

pump

ZL-2

8

Lower articulated-point shaft

of derricking cylinder

Monthly

Inject with grease

pump

ZL-2

9 Outrigger slider pads 10 Days

Grease or inject

with grease

ZL-2

10 Main / auxiliary winch Semi-annual Directly pour

90# industrial

gear oil

11 Main boom main shaft Daily

Grease or inject

with grease pump

ZL-2

12 Swing reducer Semi-annual Directly pour

90# industrial

gear oil

13 Wire-rope 10 Days Grease ZG-3

14 Pulley block (shaft) on jib 10 Days

Inject with grease

pump

ZL-2

Loading...

Loading...