8

System description

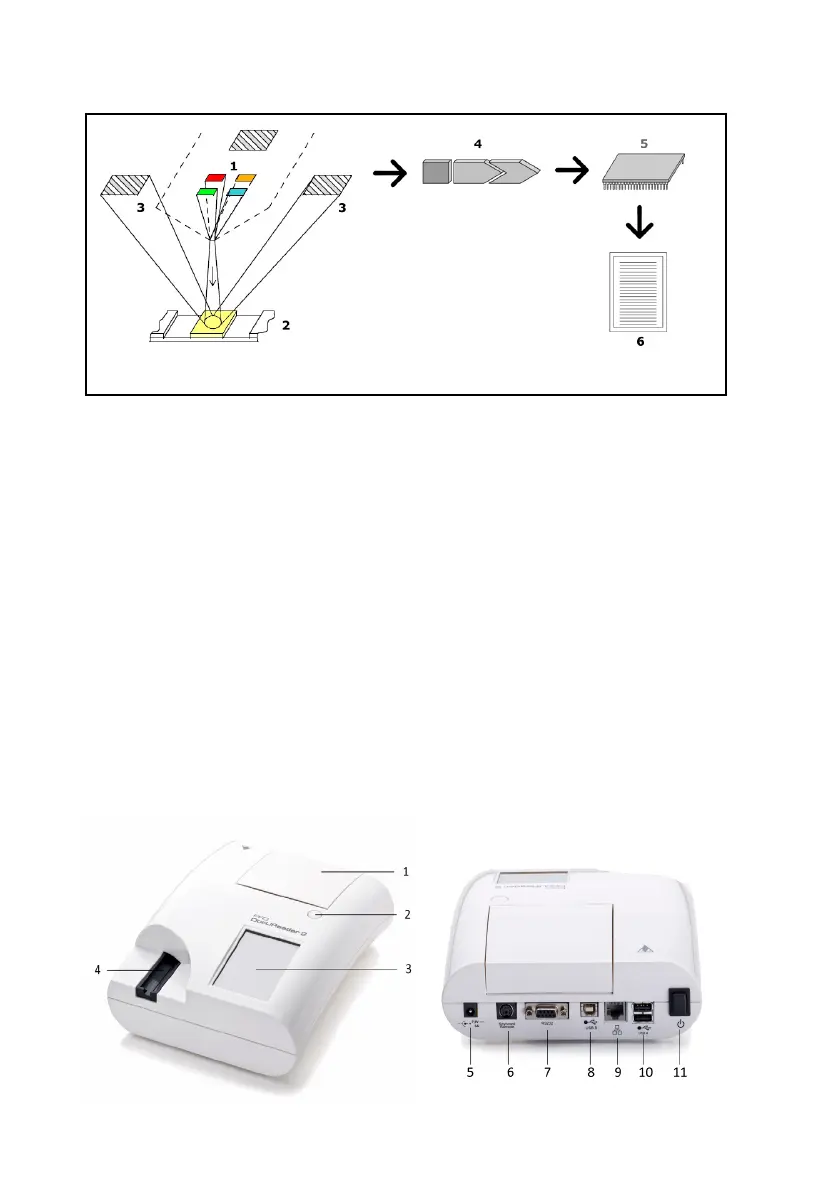

Fig. 1: Measurement principle

Each LED (1) emits light of a predefined wavelength onto the surface of the test

pad (2) from directly above the test zone. The test zone is a 3-mm circle in the

center of each pad where the test reaction is optimal.

The light from the LEDs is reflected back from the test zone with more or less

intensity. The intensity of the reflection is directly related to the concentration of

the particular analyte in the urine that the pad absorbed. Photodiode detectors (3)

positioned at optimum angles pick up the reflected light. The analogue electrical

signals from the detectors are first boosted by an amplifier (4) before they arrive at

the microcontroller (5). Here, the A/D converter in the microcontroller changes the

analogue signals into digital values. The microcontroller converts this digital data

into an absolute reflectance value by comparing it to a calibration standard. Finally,

the system calculates an evaluation value from the reflectance values, compares it

to the predefined range limits and produces a semi-quantitative result (6).

A lead (incubation) time of about 55-65 seconds between the test strips coming

into contact with the urine and the start of the measurement produce the most

accurate results.

2.2 Components & functions

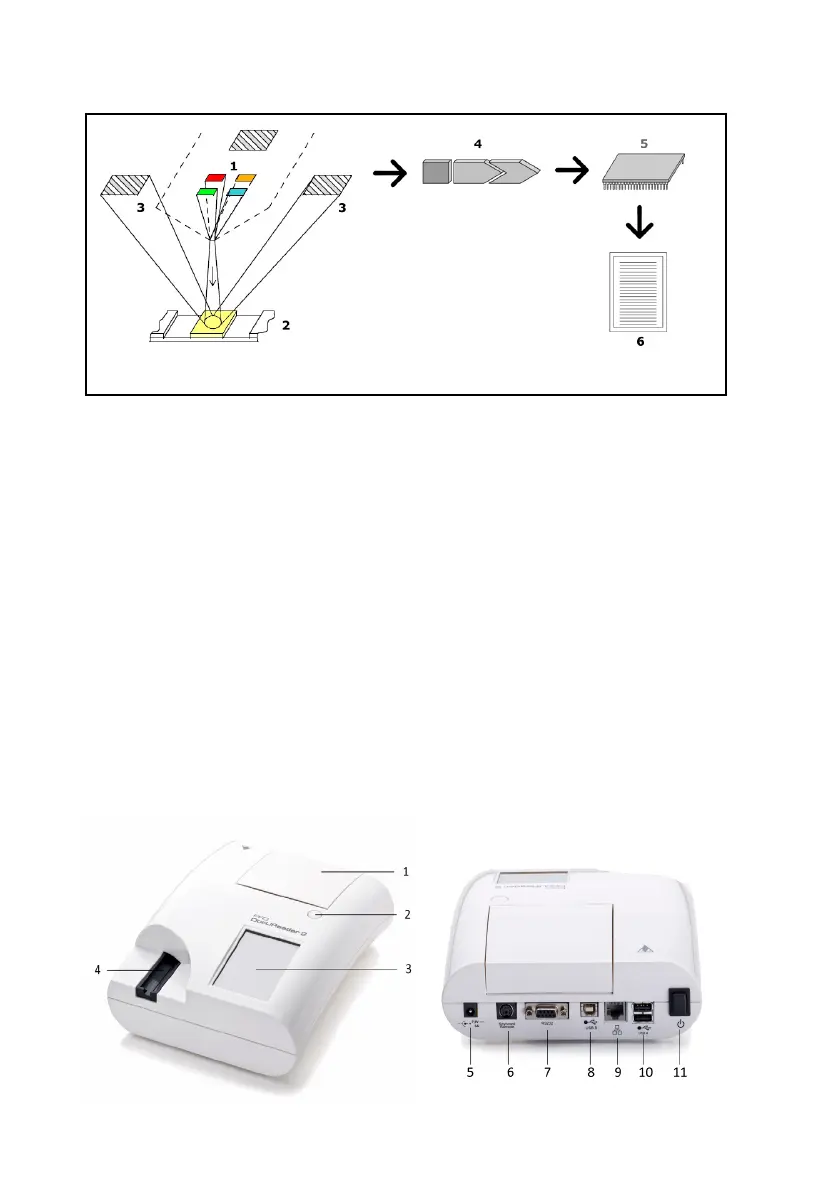

Fig. 2: Front and rear view of the analyzer, marked up

Loading...

Loading...