P. 32 - Chap. 6 Handling and installation

G

B

The machine cooling air and the heating ducts

(where relevant) must be dimensioned so that

air speed does not exceed 3 m/s. The maxi-

mum length of the ducts is 6 m. If this is not so,

fit an

auxiliary fan in the hot air duct.

Following installation of the hot air ducts, check that any back pressure, measured at the outfeed of

the hot air from the compressor, does not exceed 5-6 mm of water column.

For guidance purposes, duct cross-section area should be equal to that of the compressor hot air outlet grill

(reference FU in Figs. 14, 16, 18, 20, 22, 24).

Heat the environment if the minimum temperature required cannot be guaranteed.

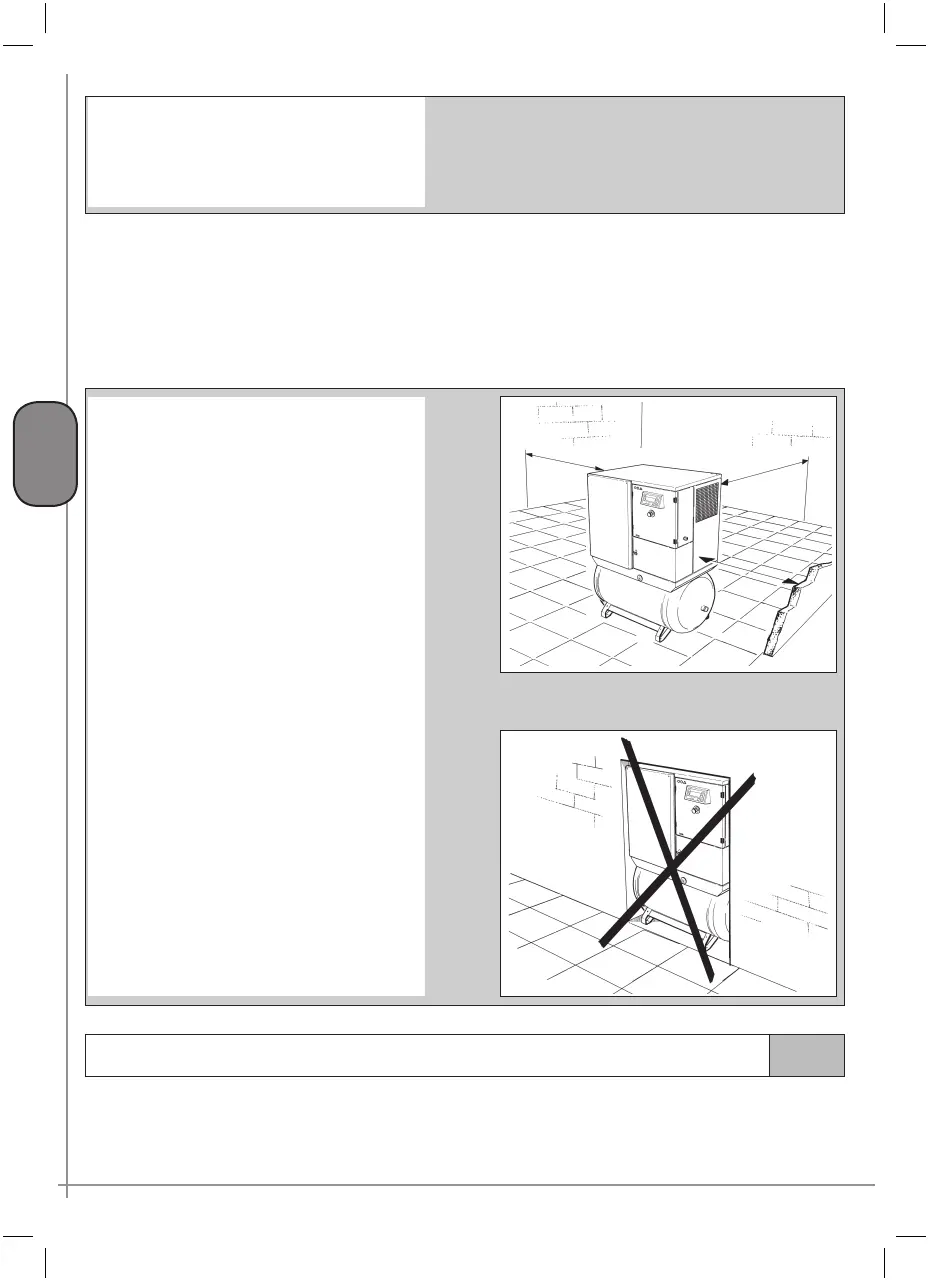

Comply with the minimum distances from the

walls shown in figure 31

The position of the compressor in the room

should allow easy inspections. If the compres

-

sor is installed in the working environment,

keep at suitable safety distance according to

the type of process carried out at the premises

in order to prevent hazards or damage to the

machine due to the products used.

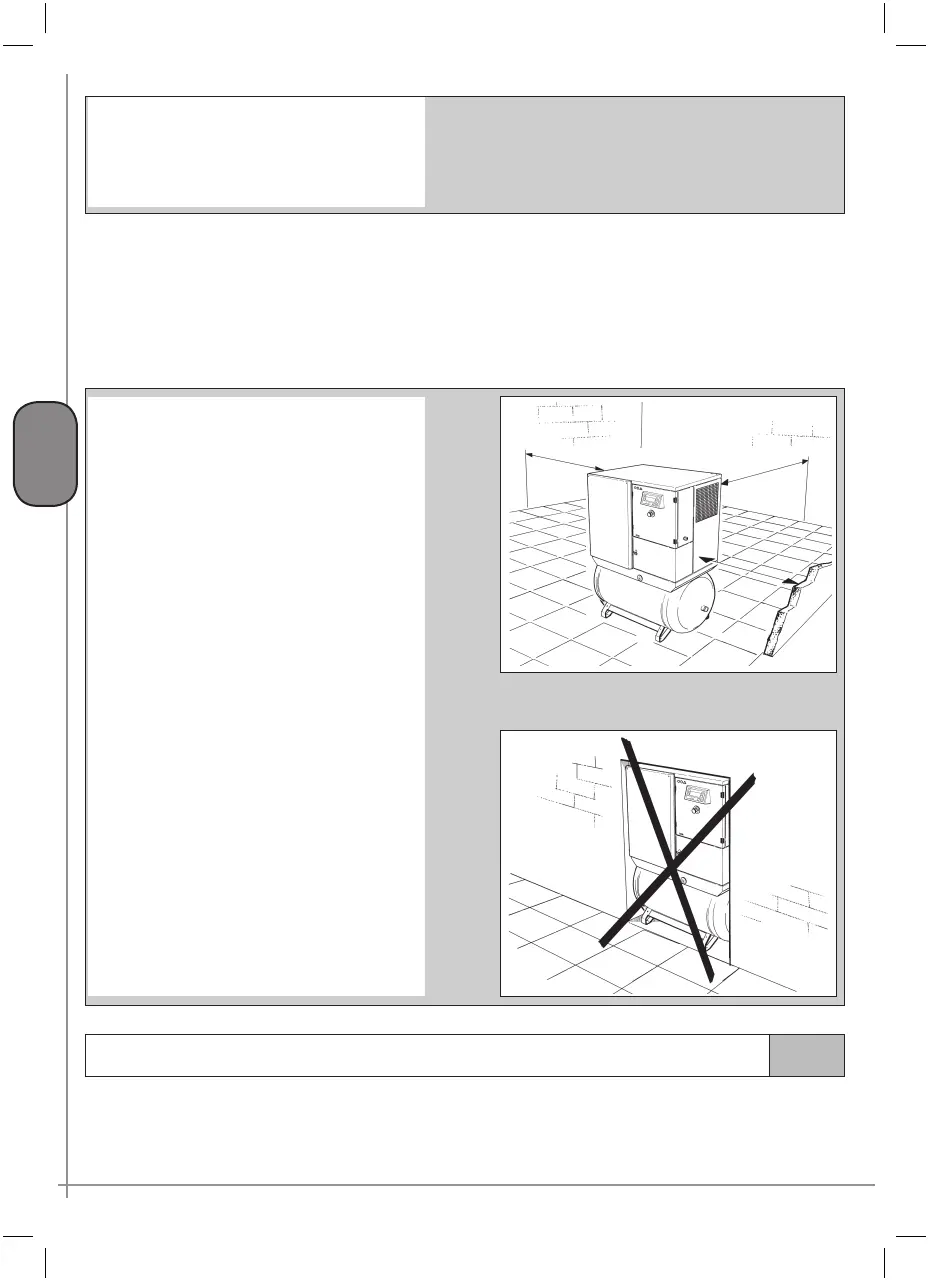

The compressor should not be installed in a

recess which does not allow correct ventila

-

tion. Hot air flow should not be obstructed in

any way and recirculation must be prevented

(Fig. 32).

Fig. 31

Fig. 32

600

600

600

6.3

Air connection

When connecting the compressor to the receiver or to the distribution line, it is good practice to insert a hose

of suitable size and specifications (pressure and temperature) connected to the

MA sleeve (Figs. 14, 16, 18,

20, 22, 24). The compressed air lines must be in perfect conditions and suitably fastened.

Loading...

Loading...