Operation Manual / A100-L

9 Disassembly and assembly / 9.12 Dismantling the gas inlet casing (≥

A180-L)

© Copyright 2021 ABB. All rights reserved. HZTL4034_EN Rev.T December 2021

9.12 Dismantling the gas inlet casing (

≥

A180-L)

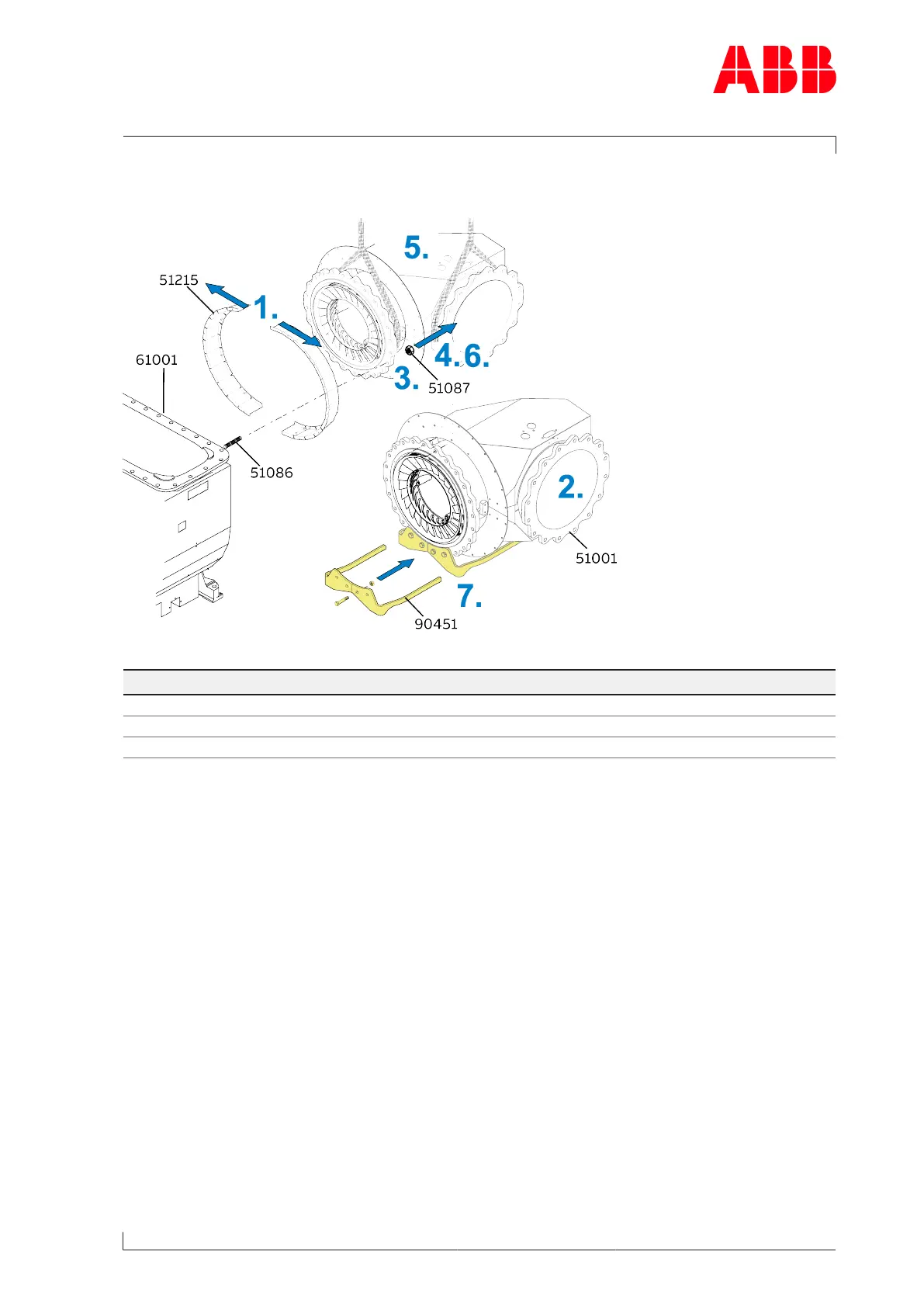

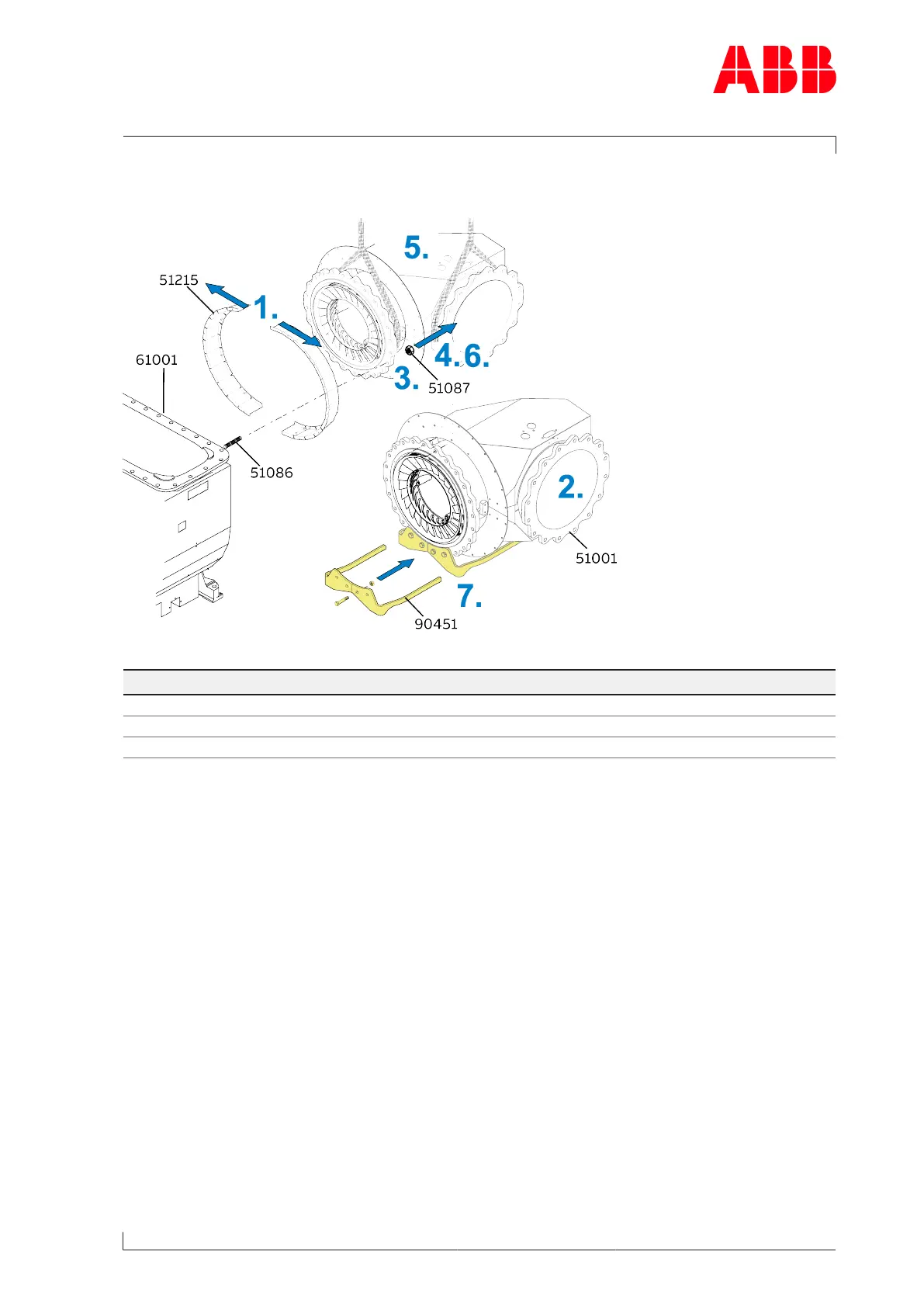

Fig.45: Dismantling the gas inlet casing (180-L and larger)

Product Maximum loosening torque [Nm]

A180-L 840

A185-L 1225

A190-L 1610

Table33: Maximum admissible loosening torque (51087)

u If a threaded stud (51086) shears off when loosening, an ABB Turbocharging Service Sta-

tion should be contacted.

u If a threaded stud (51086) works loose when removing the nut (51087), it should be refit-

ted, after disassembling the gas outlet casing, up to the stop in the gas inlet casing until

hand-tight.

u If the nut (51087) cannot be removed with the maximum permissible loosening torque, it

can be heated or removed with an appropriate tool.

1. Dismantle both halves of the insulation segment(51215) and remove with all fixing ele-

ments.

2. Detach flange connection between gas inlet casing(51001) and bellows.

3. Treat nuts (51087) with rust remover.

4. Loosen crosswise and remove all nuts(51087) except for two opposite nuts. Note max-

imum admissible loosening torque.

5. Loop around the gas inlet casing(51001) with lifting gear.

6. Loosen and remove remaining nuts(51087).

7. Fit support(90451) on gas inlet casing and put down casing.

Page 87 / 141

Loading...

Loading...