53 ACS2000 AFE 1MVA UM 3BHS297030 ZAB E01 REV. J

Parameters

The control system is configured, customized, and

tuned with a set of application parameters. The

application parameters are organized in functional

groups and have factory-set default values.

The default parameter values are adjusted during

commissioning to the specific application of the

drive to activate the specific control, monitoring

and protection functions for the driven process,

and to define the signals and data to be trans-

ferred between drive and external equipment.

The parameters and parameter groups referred to

in the signal allocation tables in this chapter are

valid for drives with software version LDOI6xxx

revision "-" and later versions.

Main circuit breaker

The main circuit breaker (MCB) is

an important switching and pro-

tection device of the drive system.

Therefore it must only be con-

trolled and monitored by the

drive.

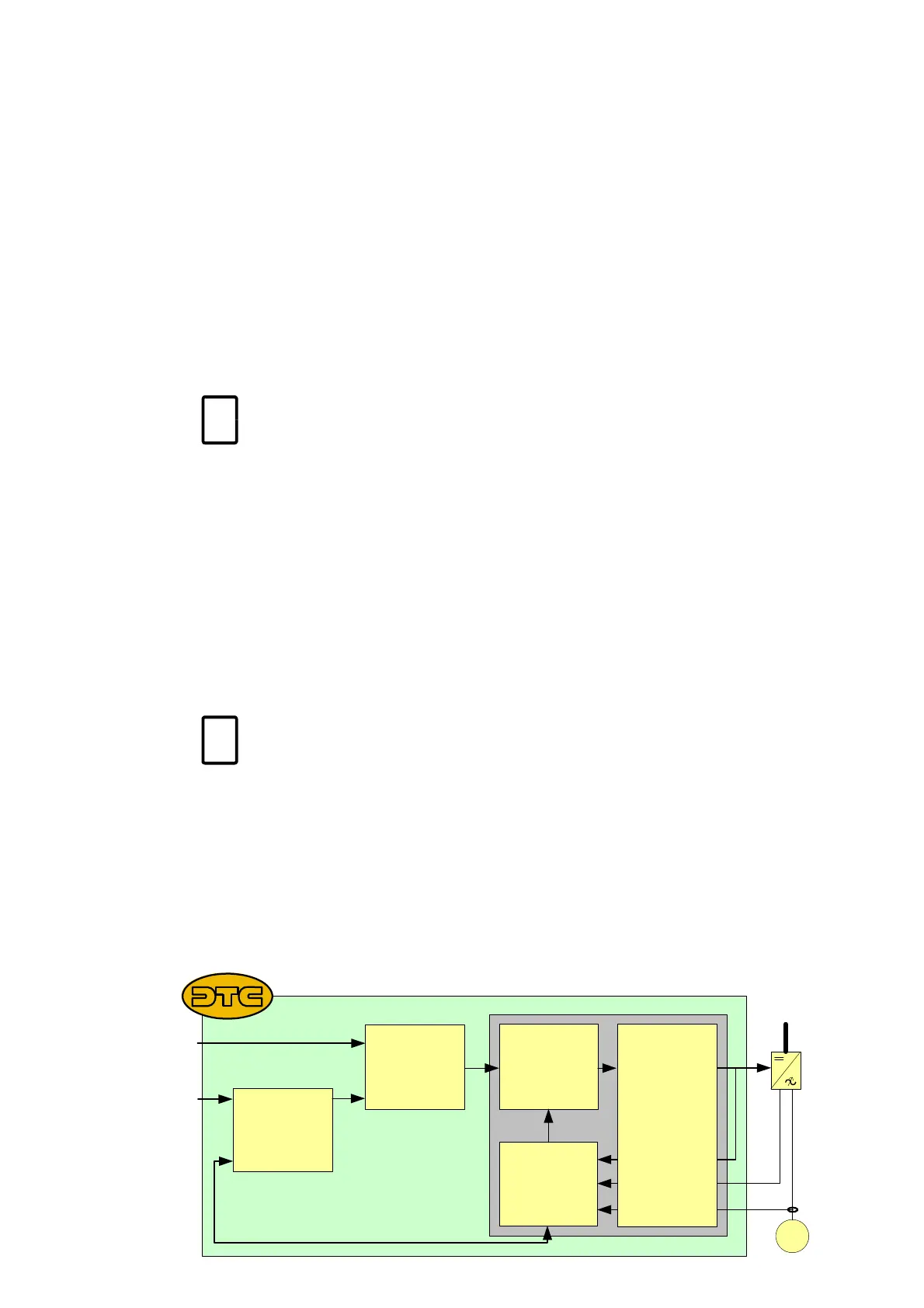

Direct torque control

The speed and torque of the motor is controlled by

DTC (Direct Torque Control). DTC provides accu-

rate speed and torque control, and high dynamic

speed response.

Switching of the semiconductors in the INU is

directly controlled in accordance with the motor

core variables flux and torque.

The measured motor currents and DC link voltages

are inputs to an adaptive motor model. The model

produces exact values of torque and flux every 25

microseconds. Motor torque and flux comparators

compare the actual values to reference values

which are produced by the torque and flux refer-

ence controllers.

Depending on the outputs from the hysteresis con-

trollers, the switching logic directly determines the

optimum switch positions every 50 microseconds

and initiates switching whenever required.

Peripheral I/O devices

The peripheral input and output devices connected

to the AMC circuit board of the INU include:

•Local CDP control panel

• I/O interfaces for parallel signal transfer to exter-

nal devices

• Optional fieldbus adapters for serial data trans-

fer to a higher-level control system

• PC-based service tools comprising:

-DriveWare

®

software tools

DriveWare

®

includes software tools such as

the commissioning and maintenance tools

DriveWindow and DriveDebug, and

DriveOPC for data transfer between ABB

drives and Windows

®

-based applications.

-DriveMonitor

(option)

DriveMonitor is a monitoring and diagnos-

tics tool that allows access to the drive from

any location in the world via a secure inter-

net connection.

For further information on the parame-

ters for signal allocation, signal type

selection, signal inversion, scaling, and fil-

tering, see signal and parameter table.

For further information, see:

• Main circuit breaker engineering

guideline

• Important note on main circuit

breaker

3-5 Direct torque control

3-5

Speed

controller

Torque-

reference

controller

Torque

flux

comparator

Motor

model

Switching

logic

Switch

positions

Voltage

Current

M

Torque reference

Speed reference

Actual speed

or

Loading...

Loading...